The best materials for modular kitchen cabinets shape how well a kitchen performs over time—affecting durability, stability, maintenance, and long-term cost. Choosing the right modular cabinet materials ensures consistent strength, cleaner installations, and fewer replacement issues. As demand rises in North America, builders and brands now prioritize the best materials for modular kitchen cabinets that support scalable production and reliable quality. This guide highlights the leading options so decision-makers can specify with confidence and protect project value.

Table of Contents

1. What Materials Are Used in Modular Kitchen Cabinets?

Modular kitchen cabinets are built using a combination of structural and decorative materials.

Choosing the best materials for modular kitchen cabinets starts with understanding how different material types contribute to strength, durability, and long-term performance. Modular kitchens rely on a combination of structural and decorative materials, each serving a specific function in the overall system.

1.1 Structural vs. Decorative Materials

Structural materials form the backbone of the system. These are the best materials for modular kitchen cabinets when stability, long-term load capacity, and installation reliability matter most.

They are typically used for carcasses, shelves, and internal framing.

Typical structural materials include:

- Engineered plywood

- MDF (Medium Density Fiberboard)

- Particle board

Decorative materials define the appearance and surface performance of the cabinet. These materials are applied to visible areas such as doors, drawer fronts, and side panels.

Common decorative materials include:

- Laminates and melamine finishes

- Acrylic and high-gloss panels

- Veneer surfaces

- Edge banding materials

Using the best materials for modular kitchen cabinets means pairing strong internal structures with durable finishes, resulting in kitchens that perform well, look cohesive, and meet long-term homeowner expectations.

1.2 Key Performance Criteria for Modular Kitchen Cabinet Materials

When selecting the best materials for modular kitchen cabinets, the following performance factors should be carefully evaluated:

- Moisture resistance: Materials must withstand humidity, steam, and frequent cleaning without swelling or delamination.

- Load-bearing strength: Cabinets should support countertops, appliances, and daily use without deformation.

- Dimensional stability: High-quality materials maintain shape and alignment over time, even under temperature changes.

- Finish adhesion: Surface finishes must bond securely to prevent peeling, chipping, or discoloration.

- Health and safety compliance: Materials should meet recognized indoor air quality and emission standards for residential use.

Choosing the best materials for modular kitchen cabinets means matching strength, finish durability, and safety requirements to project size and usage needs—ensuring kitchens that last, perform, and look consistent across time.

Learn more: Types of Kitchen Cabinet Materials

2. Core Material Categories Used in Modular Kitchen Cabinets

Choosing the right core material is essential for durability and performance. The best materials for modular kitchen cabinets balance strength, moisture management, cost, and long-term visual quality. Each substrate suits different applications, budgets, and project requirements.

2.1 MDF (Medium Density Fiberboard)

MDF is one of the most widely used materials in modular kitchen cabinet manufacturing due to its smooth surface and consistent density.

Key characteristics:

- Made from fine wood fibers bonded under heat and pressure

- Provides an even, smooth surface ideal for painted and lacquered finishes

- Commonly used for cabinet doors, drawer fronts, and decorative panels

Advantages:

- Excellent surface quality for paint and acrylic finishes

- Cost-effective and easy to machine

- Uniform density with minimal surface defects

Limitations:

- Lower moisture resistance compared to plywood

- Requires proper sealing to prevent swelling in humid environments

As a result, MDF is considered one of the best materials for modular kitchen cabinets when visual uniformity is a priority.

Learn more: What are MDF Cabinets?

2.2 Plywood

Plywood is a premium structural choice among the best materials for modular kitchen cabinets, valued for strength, rigidity, and resistance to distortion.

Key features:

- High load-bearing capacity suitable for cabinet carcasses

- Strong resistance to warping and bending

- Better screw-holding strength than MDF or particle board

Applications:

- Cabinet boxes and structural panels

- Areas requiring enhanced durability or moisture resistance

Considerations:

- Higher material cost compared to MDF

- Quality varies depending on core construction and adhesive standards

Learn more: Plywood Kitchen Cabinets Pros/Cons

2.3 Particle Board (Engineered Wood Panels)

Particle board is manufactured from wood particles bonded with resin under heat and pressure. It is commonly used in cost-sensitive modular kitchen systems.

Key characteristics:

- Uniform density and smooth surface

- Compatible with laminates and melamine finishes

- Economical choice for large-volume projects

Limitations:

- Lower moisture resistance compared to plywood

- Reduced load-bearing capacity

- Best suited for dry areas and low-impact applications

Learn more: Particle Board Cabinets

2.4 Solid Wood (Selective Use)

Solid wood is typically used selectively in modular kitchens, primarily for door frames or decorative accents rather than full cabinet construction.

Key considerations:

- Natural appearance and premium aesthetic

- Subject to expansion and contraction due to humidity changes

- Higher material and maintenance costs

This hybrid approach blends aesthetics with performance—making it a strategic addition to the best materials for modular kitchen cabinets toolkit.

3. Surface Finish Options for Modular Kitchen Cabinets

Selecting the best materials for modular kitchen cabinets goes beyond structural strength—surface finishes play a critical role in appearance, durability, and long-term performance. The right finish enhances aesthetics, protects underlying materials, and ensures consistent quality across large-scale production.

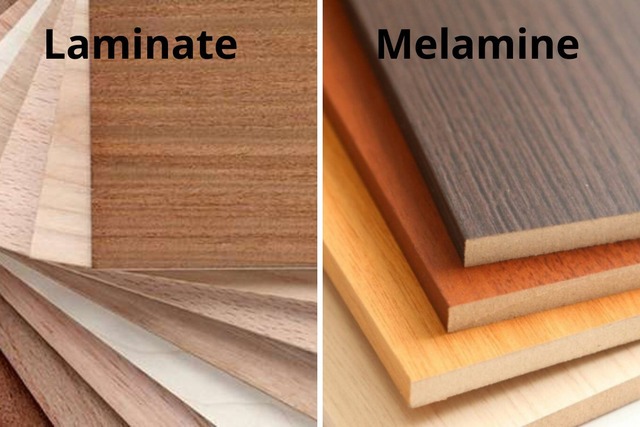

3.1 Melamine & Laminates

Melamine and laminate finishes are among the most widely used materials in modular kitchen cabinet production due to their balance of durability and cost efficiency.

Key advantages:

- High resistance to scratches, stains, and everyday wear

- Easy to clean and maintain, ideal for high-traffic kitchens

- Wide range of colors, textures, and woodgrain effects

- Stable performance in large-scale manufacturing

These finishes are commonly used in residential developments, rental projects, and budget-conscious modular kitchen systems.

Learn more: What are Melamine Cabinets?

3.2 Acrylic Finishes

Acrylic finishes are known for their smooth, high-gloss or matte appearance, making them popular in modern and premium modular kitchens.

Key characteristics:

- High-gloss or matte surfaces with excellent color consistency

- Superior visual depth compared to laminates

- Resistant to fading and discoloration when properly manufactured

Manufacturing considerations:

- Requires precise lamination and clean-room production conditions

- Demands careful handling to avoid surface damage during installation

Acrylic finishes are often selected when visual impact and contemporary design are priorities.

Learn more: Acrylic Kitchen Cabinets Pros/Cons

3.3 Painted & Lacquered Finishes

Painted and lacquered surfaces provide the highest level of design flexibility for modular kitchen cabinets. They allow customization across a wide color range and multiple texture options.

Key features:

- Multi-layer paint systems for enhanced durability

- Options for matte, satin, or high-gloss finishes

- UV-cured coatings for improved resistance to fading and wear

These finishes are ideal for premium kitchens where color consistency and long-term performance are essential.

Learn more: Painted Kitchen Cabinets

3.4 Veneer Finishes

Veneer finishes use thin layers of real wood applied over stable core materials, offering a balance between natural aesthetics and engineered performance.

Advantages include:

- Authentic wood appearance with improved dimensional stability

- Suitable for modern and high-end kitchen designs

- Reduced risk of warping compared to solid wood

Veneer finishes are commonly chosen for projects that prioritize natural textures while maintaining control over cost and durability.

4. Performance Considerations for Modular Kitchen Materials

Choosing the best materials for modular kitchen cabinets is essential for achieving long-term durability, consistent performance, and cost efficiency. Material performance directly affects how well modular kitchen cabinets withstand daily use, moisture exposure, and structural stress. For developers and cabinet brands, selecting the right materials ensures both functional reliability and long-term value.

4.1 Durability Analysis

Durability is one of the most critical factors when evaluating the best materials for modular kitchen cabinets, particularly in high-traffic residential or commercial environments.

Key durability considerations include:

- Resistance to wear, impact, and repeated daily use

- Ability to maintain structural integrity over time

- Performance under frequent opening, closing, and load-bearing conditions

High-quality modular kitchen cabinet materials such as engineered plywood and reinforced MDF deliver long-term durability while maintaining consistent appearance and performance.

4.2 Moisture & Heat Resistance Analysis

Kitchens are exposed to constant humidity, heat, and temperature fluctuations, making moisture resistance a critical factor when selecting the best materials for modular kitchen cabinets.

Important performance factors include:

- Resistance to moisture penetration near sinks and cooking zones

- Heat tolerance around ovens and appliances

- Quality of edge sealing and surface lamination

Materials with proper moisture-resistant treatment significantly reduce the risk of swelling, delamination, and structural damage over time.

Learn more: Moisture-Resistant Cabinets

4.3 Stability & Precision Analysis

Dimensional stability plays a major role in the long-term functionality of modular kitchens. The best materials for modular kitchen cabinets maintain consistent shape and alignment under varying environmental conditions.

Key considerations include:

- Resistance to warping and expansion

- Precision machining for tight tolerances

- Compatibility with modular cabinet systems

Stable materials ensure smooth drawer operation, accurate door alignment, and a refined finished appearance.

4.4 Maintenance & Lifecycle Cost Analysis

Beyond initial cost, the best materials for modular kitchen cabinets must offer long-term value through minimal maintenance and extended service life.

Key factors include:

- Ease of cleaning and stain resistance

- Lower frequency of repairs or replacements

- Reduced lifecycle cost over years of use

Materials that maintain appearance and performance over time help reduce total ownership cost for residential and commercial projects.

4.5 Health & Environmental Safety Analysis

Health and sustainability are increasingly important in modern kitchen design. Selecting certified materials helps ensure indoor safety and environmental responsibility.

Important criteria include:

- Compliance with formaldehyde emission standards (CARB, E0/E1)

- Use of low-VOC adhesives and finishes

- Contribution to healthier indoor air quality

Learn more: Low VOC Cabinets

5. Best Material Combinations for Modular Kitchen Cabinets

Selecting the best materials for modular kitchen cabinets requires matching each cabinet component with the most suitable material for performance, durability, and long-term value. The table below outlines the most effective material combinations used in professional modular kitchen systems.

| Application Area | Recommended Material | Key Benefits |

| Cabinet Carcass | Plywood / Engineered Board | High structural strength, excellent load-bearing capacity, long-term dimensional stability |

| Door Panels | MDF or Acrylic | Smooth surface finish, ideal for paint or high-gloss designs, consistent appearance |

| High-Moisture Zones | Moisture-resistant board or marine-grade plywood | Superior resistance to humidity, swelling, and water exposure |

| Premium Designs | Veneer over engineered core | Natural wood appearance with enhanced stability and reduced warping |

Using the right combination of materials allows manufacturers and developers to balance durability, aesthetics, and cost efficiency. Selecting the best materials for modular kitchen cabinets ensures long-term performance, easier maintenance, and consistent quality across residential and commercial projects.

6. Manufacturing Quality: Why Materials Alone Are Not Enough

Using the best materials for modular kitchen cabinets is only effective when supported by precise manufacturing processes. Even premium materials can underperform without proper machining, finishing, and quality control.

6.1 Precision Cutting & CNC Processing

High-accuracy CNC machining ensures consistent sizing and alignment across all cabinet components.

- Improves fit and installation accuracy

- Reduces material waste and defects

- Essential for large-scale modular kitchen cabinet production

Learn more: Cabinet Manufacturing Process

6.2 Edge Banding & Sealing Quality

Proper edge banding protects cabinet panels from moisture and impact, extending product lifespan.

- Prevents swelling and delamination

- Enhances durability of modular kitchen cabinet materials

- Improves visual finish and edge consistency

6.3 Controlled Finishing Environments

Surface quality depends heavily on controlled production conditions.

- Maintains uniform color and texture

- Supports high-performance finishes like acrylic and lacquer

- Ensures consistency across large production batches

6.4 Role of Advanced Manufacturing Technology

Modern CNC and automated systems maximize the performance of the best materials for modular kitchen cabinets by ensuring accuracy, repeatability, and long-term reliability. This combination of quality materials and advanced production is essential for scalable, high-performance modular kitchen solutions.

7. Vietnam-Based Manufacturing with European Technology: A Strategic Advantage

Vietnam has become a key global hub for producing the best materials for modular kitchen cabinets, offering a strong balance of cost efficiency, scalability, and manufacturing precision.

Many international brands now rely on Vietnam-based factories to achieve consistent quality while maintaining competitive production costs.

At the center of this shift is Casta, which combines European production standards with a skilled local workforce to deliver high-quality modular kitchen solutions for residential and commercial projects.

7.1 High-Quality Material Processing at Scale

Casta’s production facilities are built to support large-volume manufacturing while maintaining strict quality control. By using carefully selected substrates and engineered panels, Casta ensures that the best materials for modular kitchen cabinets perform consistently across all orders.

Key advantages include:

- Controlled material sourcing and stable quality

- Consistent output across large production batches

- Reduced variation between project phases

7.2 European CNC and Finishing Systems

Casta operates advanced European CNC machinery and automated finishing lines to ensure precision and uniformity. These systems support:

- Accurate cutting and drilling for modular components

- Smooth, consistent surface finishing

- Reduced production errors and rework

This technology enables reliable production of high-performance modular kitchen cabinets at scale.

7.3 Consistent Output for Large-Scale Modular Projects

Large residential and mixed-use developments require repeatability and precision. Casta’s manufacturing process ensures uniform cabinet dimensions, finishes, and performance across all production runs.

By combining modern European machinery with strict quality control, Casta delivers dependable, scalable solutions using the best materials for modular kitchen cabinets, meeting the demands of long-term, high-volume projects.

Learn more: Casta’s outstanding international projects

8. Case Application: Material Selection for a Modular Kitchen Project

In large residential developments, choosing the best materials for modular kitchen cabinets is essential for maintaining quality, efficiency, and long-term performance.

Project overview:

The project required a consistent, cost-effective cabinet system that could be produced at scale while meeting durability and aesthetic standards.

Selected material combination:

- Cabinet carcass: Moisture-resistant engineered boards for strength and stability

- Door panels: MDF with acrylic or laminate finishes for a clean, modern look

- Edge treatment: High-quality edge banding to improve durability and lifespan

Performance outcomes:

- Strong durability and long-term performance

- Controlled costs through standardized materials

- Faster installation due to precise manufacturing

This approach ensured reliable results across all units while maintaining the performance expected from the best materials for modular kitchen cabinets.

Learn more: Modular Kitchen Cabinets

9. Decision Checklist: Choosing the Best Materials for Modular Kitchen Cabinets

Selecting the best materials for modular kitchen cabinets requires a clear evaluation framework to ensure long-term performance, safety, and scalability. Use the checklist below to guide material selection for residential, commercial, or large-scale projects:

- Does the material meet durability requirements?

The material should withstand daily use, impact, and environmental stress without warping, cracking, or surface failure.

- Is the material suitable for modular construction?

Materials must support standardized sizing, precise machining, and repeatable installation across multiple units.

- Are surface finishes stable and compatible?

Finishes should adhere properly, resist peeling or discoloration, and maintain appearance over time.

- Does the material comply with health and safety standards?

Look for compliance with CARB, E0/E1, or other recognized indoor air quality regulations to ensure safe indoor environments.

- Can the material be produced consistently at scale?

Reliable materials should support high-volume production without variations in quality, color, or performance.

Using this checklist helps ensure that selected materials support long-term durability, consistent quality, and efficient production—key factors in delivering successful modular kitchen projects.

Learn more: Sustainable Furniture Materials

10. Frequently Asked Questions

What is the best material for modular kitchen cabinets?

Are acrylic finishes durable for kitchens?

Which material performs best in humid environments?

Can modular kitchen materials be customized?

Do material choices affect project cost significantly?

Top Cabinet Manufacturers in Florida: A Capability-Based Buy...

Cabinet manufacturers in Florida play a critical role in one of the fastest-growing construction markets in North Americ...

01/10/2026 | David Nguyen

Top North Carolina Cabinet Manufacturers | Best NC Kitchen ...

North Carolina cabinet manufacturers have long been trusted across the U.S. thanks to the state’s deep heritage in woodw...

01/08/2026 | David Nguyen

Top Cabinet Manufacturers in Arizona | Best Arizona Kitchen ...

Cabinet manufacturers in Arizona have gained increasing attention as construction activity accelerates across Phoenix, T...

01/06/2026 | David Nguyen

Top Cabinet Manufacturers Indiana | Best Indiana Kitchen Cab...

Cabinet manufacturers Indiana have become increasingly relevant as contractors and developers look for dependable Midwes...

01/04/2026 | David Nguyen

Contact us

Casta is always ready to listen and answer all customers' questions