Advanced cabinet technology significantly enhances the quality, efficiency, and sustainability of modern cabinetry production, providing critical competitive advantages for North American contractors and cabinet/furniture brands. This article defines cabinet technology, details the top 10 innovations reshaping the industry, analyzes current market trends, and illustrates how Casta Cabinetry integrates these advancements. With over 20 years of expertise, Casta combines high-quality production at its Vietnam facility, using precision European machinery, iterative customization processes (typically 3–5 design rounds), FSC/PEFC-certified and low VOC materials, and robust logistics ensuring over 98% on-time delivery—effectively accommodating large-scale orders without compromising quality.

Table of Contents

1. Understanding Cabinet Technology in the Modern Market

1.1 Defining Cabinet Technology

- Cabinet technology represents the strategic integration of advanced machinery, digital design systems, and sustainably certified materials to manufacture high-performance cabinetry with greater precision and quality than traditional methods.

- Core Elements of Cabinet Technology:

- Advanced Machinery:

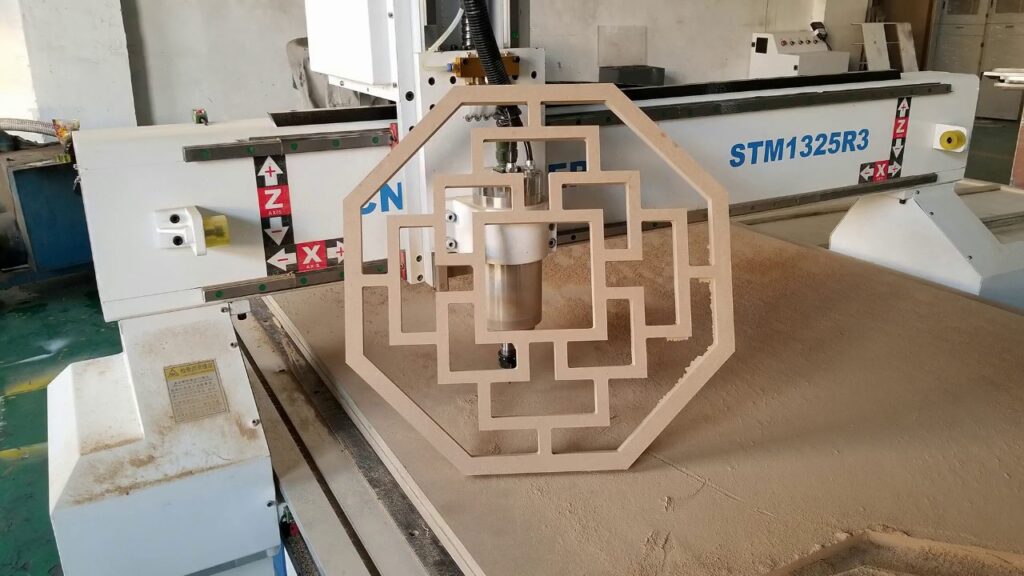

- CNC Equipment: Provides precise cutting, drilling, and milling, achieving tolerances within 0.1% accuracy, significantly reducing waste and enhancing overall product consistency.

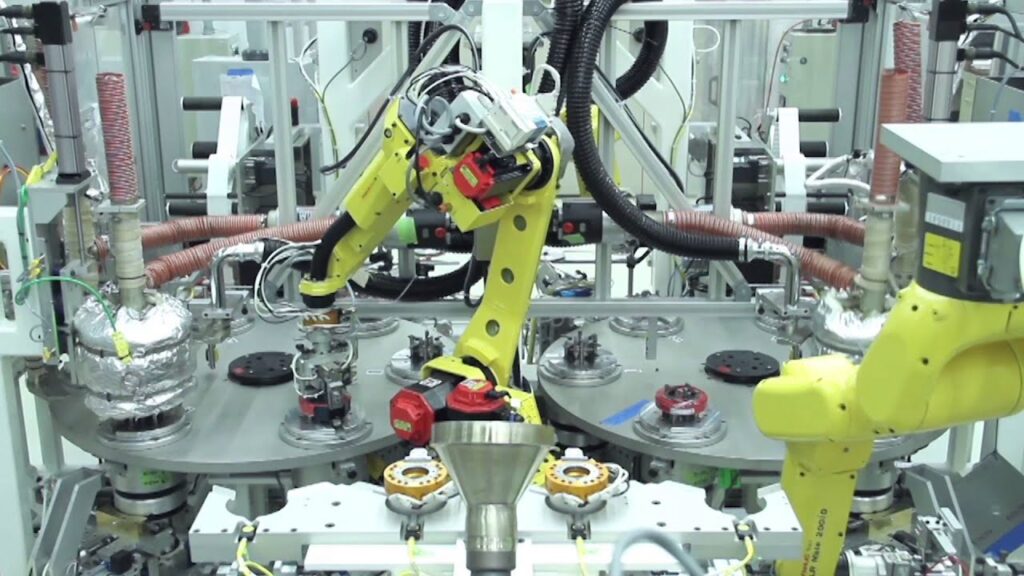

- Robotic Systems & Automation: Enable rapid, consistent assembly processes, reducing production time and labor costs, while lowering defect rates below 2%.

- Digital Design Tools:

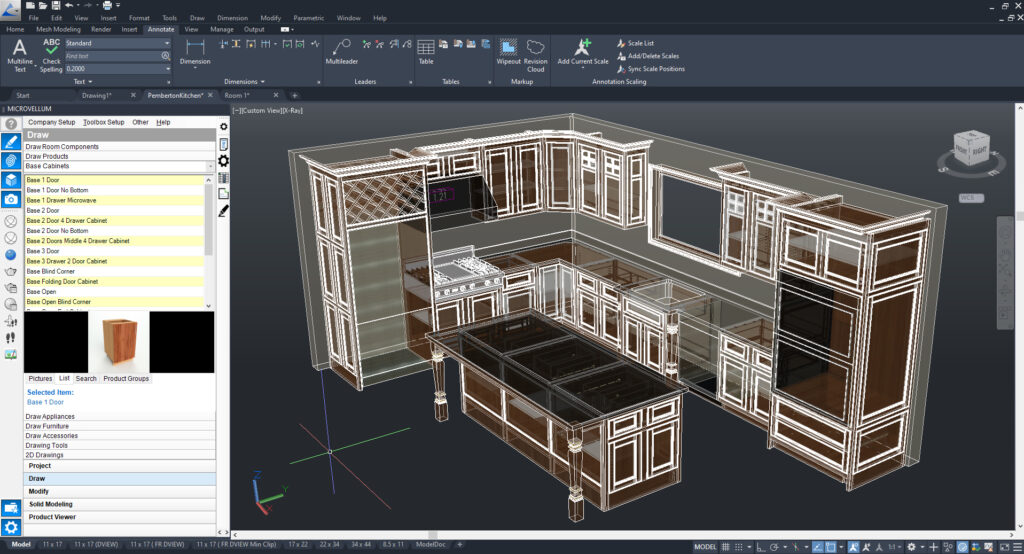

- 3D Visualization Software: Offers interactive digital prototypes, allowing clients and manufacturers to visualize finished cabinets accurately, streamlining customization.

- AI-Driven Optimization: Utilizes artificial intelligence algorithms to optimize layouts, minimize material usage, and forecast potential production issues, thus boosting efficiency by up to 15%.

- Certified Materials:

- FSC/PEFC-Certified Wood: Ensures sourcing from responsibly managed forests, aligning with sustainability initiatives and enhancing brand reputation.

- Low VOC Panels: Compliant with stringent standards like CARB (California Air Resources Board) and JIS (Japanese Industrial Standards), improving indoor air quality and overall product safety.

- Advanced Machinery:

- Primary Applications:

- Kitchen Cabinet Technology: Incorporates features like modular design, smart storage solutions, and durable finishes, transforming kitchen usability and aesthetics.

Learn more: The Ultimate Guide to Modern Design Kitchen Cabinets

- Technology Storage Cabinets: Utilized in commercial or industrial settings, these cabinets employ smart sensors and IoT integration for efficient inventory management and security.

1.2 Industry Standards & Market Drivers

- Key Industry Standards Governing Cabinet Technology:

- ASTM (American Society for Testing and Materials): Provides rigorous protocols to test cabinetry for durability, material strength, and resilience against environmental factors.

- ANSI (American National Standards Institute): Defines strict quality and safety benchmarks, ensuring cabinetry products consistently meet industry and consumer expectations.

- CARB (California Air Resources Board): Enforces formaldehyde emission regulations, safeguarding indoor air quality and public health, critical for cabinetry utilized in residential and commercial interiors.

- FSC/PEFC (Forest Stewardship Council/Programme for the Endorsement of Forest Certification): Sets standards for sustainably harvested materials, promoting responsible environmental practices within the cabinetry industry.

- JIS (Japanese Industrial Standards): Establishes precise quality and safety standards, particularly influential for manufacturers aiming for global market competitiveness.

- Market Drivers Influencing Cabinet Technology Adoption:

- Sustainability Demand: Consumer awareness and regulatory policies emphasize sustainable, health-safe cabinetry, pushing manufacturers toward certified, environmentally responsible materials.

- Efficiency & Cost Reduction: Competitive market conditions drive manufacturers to reduce waste and streamline operations through automation, CNC precision, and AI-driven process optimization.

- Customization Needs: Increasingly, contractors and consumers require cabinetry that meets specific aesthetic, functional, and spatial criteria. Digital design tools and modular systems effectively address these personalized demands.

- Quality Expectations: Heightened industry standards demand cabinetry with enhanced durability, flawless finishes, and consistent reliability, necessitating integrated quality control systems and advanced cabinet technology practices.

2. Top 10 Cabinet Technology Innovations

2.1 Advanced CNC and Robotic Cutting

- Description: Advanced CNC machinery combined with robotic cutting technologies represents a breakthrough in cabinet manufacturing, significantly boosting accuracy and reducing material waste.

- Key Benefits:

- Precision cutting accuracy within 0.1% tolerance ensures consistently high-quality cabinetry.

- Material waste minimized to less than 2%, enhancing sustainability and reducing costs.

- Increased manufacturing speed, improving production timelines and overall efficiency.

- Impact on Industry: Contractors and cabinet brands benefit from superior-quality end products, faster project completions, and reduced environmental footprints.

Traditional Cutting vs. CNC & Robotic Cutting

Before the advent of CNC and robotic systems, cabinet production relied heavily on manual cutting techniques. This traditional method often resulted in:

- Lower Precision: Manual cutting typically had higher tolerances, leading to variability in dimensions and inconsistencies in quality.

- Higher Material Waste: Errors in manual cutting frequently resulted in 5-10% waste, increasing both cost and environmental impact.

- Slower Production: The labor-intensive nature of traditional cutting slowed down production, extending lead times and increasing labor costs.

- Inconsistent Quality: Variability in human performance can lead to non-uniform products, affecting the overall appearance and functionality of the cabinets.

With CNC and robotic cutting, these challenges are effectively addressed:

| Aspect | Traditional Cutting | CNC & Robotic Cutting |

| Precision | Lower accuracy, higher tolerance variability | High precision with tolerances as low as 0.1% |

| Material Waste | 5-10% waste due to manual cutting errors | Less than 2% waste through automated processes |

| Production Speed | Slower, labor-intensive processes | Faster, streamlined production reducing lead times |

| Consistency | Quality varies with manual methods | Uniform, high-quality output with strict repeatability |

| Labor Efficiency | High labor dependency and cost | Reduces manual labor, lowering overall production costs |

2.2 Digital Design & 3D Visualization Tools

- Description: Modern digital design software enables detailed 3D cabinet modeling, providing precise visualization and customization before physical production begins.

- Key Benefits:

- Real-time revisions and client feedback integrated rapidly (typically 3–5 rounds), minimizing costly production errors.

- Reduced design-related production errors by up to 40%, streamlining workflows and cutting project timelines significantly.

- Enhanced client satisfaction through accurate, lifelike digital presentations.

- Impact on Industry: Dramatically reduces rework and increases efficiency, critical for contractors aiming for accuracy, customization, and rapid project delivery.

2.3 Smart Storage Solutions with IoT Integration

- Description: Cabinets equipped with IoT technology include integrated sensors and smart connectivity, revolutionizing storage management and maximizing space utilization.

- Key Benefits:

- Intelligent sensor technology automatically tracks and organizes stored items, enhancing convenience and space efficiency.

- User-friendly digital interfaces facilitate easy interaction and management of cabinetry functions.

- Market demand is growing rapidly, with annual growth projected at 9%, highlighting consumer preference for smart home technology.

- Applications in Kitchen Cabinets:

- In upscale kitchens, IoT-integrated cabinets help monitor ingredient freshness, automatically alerting users when items need replenishment.

- Smart systems can adjust internal conditions to preserve food quality, ensuring optimal storage of perishable items.

- Enhanced data analytics provide insights into usage patterns, enabling better planning and inventory management.

- Impact on Industry: IoT integration addresses evolving consumer preferences for intelligent storage, driving competitive differentiation for cabinet manufacturers.

2.4 Automated Assembly Lines

- Description: Automated robotic assembly lines elevate production consistency and significantly lower labor costs, redefining operational efficiency.

- Key Benefits:

- Labor cost savings averaging 25%, substantially reducing overhead and enhancing competitive pricing.

- Consistent production quality, with defect rates reliably kept below 2%, ensures superior cabinetry durability and reliability.

- Accelerated production speed through continuous automated assembly operations.

- Impact on Industry: Enables manufacturers to deliver high-volume, high-quality orders swiftly, appealing strongly to contractors managing tight project schedules.

2.5 Sustainable Production & Certified Materials

- Description: Cabinet manufacturers increasingly employ FSC/PEFC-certified wood and low VOC-engineered panels, responding to growing consumer and regulatory demands for sustainable products.

- Key Benefits:

- Extended cabinet lifespan exceeding 20 years, improving consumer satisfaction and brand reputation.

- Compliance with stringent environmental regulations (CARB, JIS), ensuring safety and environmental responsibility.

- Strong market appeal among eco-conscious consumers and regulatory-driven markets.

- Economic Advantages: Sustainable production practices can reduce energy consumption and waste, leading to long-term cost savings and lower operational expenses.

- Impact on Industry: Sustainability practices position brands favorably amid growing regulatory requirements and consumer preferences for environmental responsibility.

Learn more: Cabinet certification

2.6 Modular & Adaptable Cabinet Systems

- Description: Modular cabinetry designs offer flexible, easy-to-assemble solutions that simplify installation and enable rapid customization and reconfiguration.

- Key Benefits:

- Reduces installation times by up to 30%, significantly shortening project completion timelines.

- Facilitates easy adjustments and expansions based on changing customer needs or spatial requirements.

- Cost-effective logistics and simplified inventory management due to standardized modular components.

- Impact on Industry: Modular systems appeal strongly to contractors and brands that require speed, flexibility, and scalability.

2.7 AI-Driven Design Optimization

- Description: AI software applications are transforming cabinetry design by optimizing layouts and material usage, delivering superior project outcomes and resource savings.

- Key Benefits:

- AI optimization achieves approximately 15% material savings through more efficient cutting layouts and reduced waste.

- Enhances profitability by improving efficiency in both design and manufacturing processes.

- Predictive analytics minimizes errors, ensuring smoother production processes and lower costs.

- Impact on Industry: AI-driven optimization strengthens market competitiveness through cost savings and superior operational efficiency.

2.8 Energy-Efficient Manufacturing Processes

- Description: Adoption of energy-efficient manufacturing technologies reduces energy use and environmental impacts, aligning with global sustainability targets.

- Key Benefits:

- Energy consumption reduced by up to 35%, leading to substantial operational cost savings.

- Compliance with environmental standards enhances brand positioning in sustainability-focused markets.

- Positive environmental impact aligns corporate strategies with customer and regulatory sustainability expectations.

- Impact on Industry: Energy-efficient processes offer financial and reputational benefits, increasingly vital for brand differentiation.

2.9 Innovative Finishing Techniques & Coatings

- Description: New UV-cured finishes and advanced coating techniques significantly enhance cabinets durability, aesthetic appeal, and environmental compliance.

- Key Benefits:

- UV-curing reduces VOC emissions significantly, improving indoor air quality.

- Enhanced surface durability extends cabinetry life by 10 years or more compared to traditional finishing methods.

- Attractive, consistent finishes appeal to consumers demanding both aesthetics and functionality.

- Impact on Industry: Innovations in finishing techniques elevate product quality, aesthetics, and market appeal.

2.10 Integrated Quality Control & Data Analytics

- Description: Digital quality control systems using real-time analytics drive continuous improvement, significantly enhancing production quality and efficiency.

- Key Benefits:

- Reduction of production defects to under 2%, substantially enhancing product reliability.

- Real-time data analytics enable immediate identification and correction of issues during manufacturing, minimizing downtime and waste.

- Streamlined production management improves operational visibility and decision-making.

- Impact on Industry: Digital analytics transform production processes, delivering measurable improvements in quality, reliability, and profitability.

3. How Casta Implements & Excels in Cabinet Technology

Casta Cabinetry expertly integrates advanced cabinet technology into their sophisticated, large-scale manufacturing operations in Vietnam. By investing strategically in cutting-edge machinery, sustainable processes, and digital design capabilities, Casta effectively meets the complex requirements of North American contractors, cabinet brands, and furniture companies.

Here's an in-depth look at how they achieve excellence through modern cabinet technology:

3.1 Precision Production Using Advanced CNC Machinery and Robotics

- High-Tech Machinery Investment:

- Casta has invested over €6 million in top-of-the-line European CNC machines and robotic systems, ensuring unmatched precision and efficiency in cabinetry production.

- Their production lines consistently achieve cutting accuracy within an impressive 0.1% tolerance, guaranteeing uniform quality and precision across all cabinet products.

- This precision translates into flawless installations and superior product performance, reducing rework and ensuring that every cabinet meets high-quality standards.

- Waste Minimization and Efficiency:

- Advanced cabinet technology helps reduce material waste to under 2%, significantly lowering costs and enhancing environmental sustainability.

- Robotic automation and advanced cutting systems streamline manufacturing processes, dramatically reducing defects and increasing overall productivity.

- These efficiencies result in faster turnaround times, lower costs, and products that require less maintenance, directly benefiting projects with reliable, long-lasting cabinetry.

3.2 Customized Cabinetry Through Digital Design and 3D Visualization

- Sophisticated Digital Customization Tools:

- Casta employs advanced 3D visualization software, enabling highly accurate digital modeling and detailed customization tailored precisely to client requirements.

- Their digital design process typically involves 3–5 iterative design rounds, providing flexibility for contractors and cabinet brands to achieve the perfect, tailored cabinetry solutions.

- Reduced Errors and Improved Accuracy:

- By utilizing detailed digital previews and real-time client interactions, Casta reduces design-related errors by approximately 40%, significantly minimizing costly adjustments and production delays.

- Enhanced accuracy in digital design ensures that final products align perfectly with client expectations, thereby increasing customer satisfaction and project efficiency.

Learn more: Casta’s OEM Cabinet Manufacturer

3.3 Commitment to Sustainability and Certified Material Usage

- Environmentally Certified Wood & Panels:

- Casta rigorously sources FSC and PEFC-certified wood materials, reflecting a strong commitment to sustainable forestry and eco-responsible manufacturing practices.

- They exclusively use low VOC-engineered panels compliant with strict international standards such as CARB (California Air Resources Board) and JIS (Japanese Industrial Standards), ensuring health safety and superior indoor air quality.

- Long-Term Durability and Compliance:

- Cabinetry produced under Casta’s stringent sustainability guidelines ensures product life spans exceeding 20 years, making them ideal for long-term residential and commercial projects.

- Sustainability-focused practices also position their products favorably in eco-conscious North American markets, aligning with regulatory demands and consumer preferences.

Learn more: Casta’s ISO-Qualified Cabinet Certification: Setting the Gold Standard for Quality and Reliability

3.4 Robust Logistical Reliability and Delivery Excellence

- Advanced Logistics and Real-Time Tracking:

- Leveraging digital logistics management systems, Casta Cabinetry maintains an exceptional on-time delivery performance of over 98%, significantly surpassing industry averages.

- Contractors and furniture brands benefit from Casta’s reliable delivery schedules, critical for effective project planning and client satisfaction.

- Efficient Handling of Large-Scale Orders:

- With streamlined logistics processes supported by digital analytics, Casta efficiently accommodates large-volume orders, offering seamless scalability and timely fulfillment.

- Their ability to handle complex, high-volume orders without sacrificing customization or quality makes them a preferred choice among large-scale cabinet procurement projects in North America.

Learn more: Lead Times & Supply Chain Resilience: Navigating Potential Disruptions

3.5 Scalable and Efficient Bulk Order Production

- Automated Production Capabilities:

- The integration of advanced automated assembly lines and modular manufacturing systems allows Casta to rapidly scale production according to specific project demands.

- Modular designs, driven by sophisticated cabinet technology, significantly reduce installation and assembly times, enabling quicker project turnaround for contractors and commercial clients.

- Flexible Manufacturing Solutions:

- Casta’s production technology supports diverse requirements, from small, highly customized cabinetry orders to extensive standardized bulk productions.

- Their automated processes and standardized modular systems significantly enhance operational efficiency, positioning Casta as a versatile partner for cabinet brands seeking efficient, adaptable manufacturing solutions.

Learn more: Casta’s Outstanding International Projects

By continually refining their use of advanced cabinet technology, Casta Cabinetry solidifies their position as a market leader, effectively addressing evolving customer demands for precision, sustainability, and customization in cabinetry production.

4. Market Trends & Consumer Demand Analysis

The demand for advanced cabinet technology in North America is rapidly expanding, as contractors, cabinet brands, and furniture companies increasingly adopt innovative solutions to meet rising industry standards and consumer expectations. The strategic use of sophisticated cabinet technology enables significant improvements in efficiency, quality, sustainability, and customization, positioning companies advantageously in this highly competitive market.

Embracing modern kitchen cabinet technology is increasingly important for maintaining a competitive edge. Companies that integrate these advanced solutions are enjoying benefits such as reduced production costs, faster installation, and enhanced durability. Those who delay may find it challenging to keep pace with industry trends and evolving consumer demands, potentially affecting their long-term success.

4.1 Current Industry Data & Growth Projections for Cabinet Technology

- Robust Market Growth in Cabinet Technology:

- Industry analysis forecasts a robust annual growth rate of 5-7% for advanced cabinet technology adoption through 2030, driven by the growing demand for efficient, precise, and sustainable cabinetry solutions

- Increasing integration of robotics, CNC automation, digital design, and sustainable production processes is reshaping market dynamics.

- Rise of Modular and RTA Kitchen Cabinet Technology:

- Specialized segments such as modular and Ready-to-Assemble (RTA) cabinetry are rapidly gaining popularity, driven by their suitability for swift installation and customization flexibility.

- Market data indicates substantial year-over-year growth in modular kitchen cabinet technology, driven primarily by contractors requiring faster project turnarounds and reduced installation expenses.

4.2 Contractor Preferences & Consumer Behavior towards Cabinet Technology

- Priority on Quick Installation & Efficiency:

- Contractors increasingly emphasize cabinetry that enables rapid, efficient installation to shorten overall project timelines.

- Approximately 80% of commercial projects now explicitly require modular or RTA cabinetry, highlighting contractors' growing reliance on advanced cabinet technology to improve operational efficiency and reduce labor costs

Learn more: Top 10 RTA cabinet supplier and manufacturers

- Growing Demand for Advanced Customization Capabilities:

- North American contractors and cabinet brands strongly favor highly customizable cabinetry, prompting manufacturers to incorporate advanced digital design and 3D visualization tools as essential components of their cabinet technology offerings.

- Digital customization capabilities allow for real-time modifications, significantly enhancing client satisfaction and reducing costly post-production adjustments.

Learn more: Best custom cabinet manufacturers

- Rising Quality & Durability Standards:

- The industry expectation for product quality is increasingly stringent, demanding defect rates lower than 2%, contrasting sharply with the typical 5-10% defect rates associated with traditional cabinetry methods.

- Digital analytics and integrated quality control systems within advanced cabinet technology solutions provide essential tools to meet these heightened expectations consistently.

Learn more: Industrial Cabinets Made in Vietnam: Durability and Functionality for Demanding Applications

- Emphasis on Sustainable and Health-Safe Cabinet Technology:

- Market demand is strongly driven by consumer and regulatory preferences for sustainable, certified materials and low-emission cabinetry solutions.

- Manufacturers utilizing FSC/PEFC-certified wood, CARB-compliant panels, and low VOC-emitting materials significantly enhance their competitive positioning by aligning closely with market trends emphasizing health and environmental safety.

Learn more: Non toxic kitchen cabinets

4.3 Comparative Analysis: Traditional vs. Advanced Cabinet Technology

An insightful comparison between traditional cabinetry methods and advanced cabinet technology clearly highlights the considerable advantages gained by adopting innovative, technology-driven processes:

| Factor | Traditional Cabinets | Advanced Cabinet Technology |

| Customization Level | Limited | Extensive (Digital tools & Modular systems) |

| Production Efficiency | Moderate | High (Robotics & CNC automation) |

| Defect Rate | 5-10% | <2% (Precision & Analytics) |

| Assembly & Installation | Slow, manual assembly | Rapid (Automated, Modular solutions) |

| Environmental Impact | Moderate to High | Low (FSC-certified materials, energy-efficient processes) |

| Long-term Cost Savings | Low | High (Durability, efficiency, reduced defects) |

4.4 Future Outlook & Competitive Advantages of Advanced Cabinet Technology

- Sustained Innovation in Cabinet Technology:

- Future market forecasts indicate sustained growth driven by continuous innovation in digitalization, automation, AI optimization, and eco-friendly production practices.

- Cabinet manufacturers investing in advanced cabinet technology will achieve significant competitive advantages in terms of production efficiency, market responsiveness, and customer satisfaction.

- Strategic Importance for North American Contractors:

- North American contractors and furniture brands prioritizing advanced cabinet technology stand to benefit substantially through improved project timelines, enhanced product quality, and alignment with sustainable regulatory standards and consumer preferences.

- Adopting advanced kitchen cabinet technology and smart technology storage cabinets solutions presents clear opportunities for market differentiation and sustained competitive growth.

Learn more: Leading kitchen cabinet manufacturers

5. Conclusion

Embracing cabinet technology innovations brings considerable advantages in precision, sustainability, and efficiency, directly benefiting contractors, brands, and consumers. North American businesses seeking competitive advantages should consider partnering with industry leaders like Casta Cabinetry to leverage these technological benefits.

Ready to enhance your cabinetry projects with advanced technology? Contact Casta Cabinetry for expert consultation and solutions tailored to your needs.

6. Frequently Asked Questions (FAQs)

What exactly is cabinet technology?

Why should contractors adopt advanced cabinet technology?

How does Casta Cabinetry maintain precision in production?

What sustainable practices are integrated by Casta Cabinetry?

Does adopting advanced cabinet technology increase costs significantly?

Top Cabinet Manufacturers in Florida: A Capability-Based Buy...

Cabinet manufacturers in Florida play a critical role in one of the fastest-growing construction markets in North Americ...

01/10/2026 | David Nguyen

Top North Carolina Cabinet Manufacturers | Best NC Kitchen ...

North Carolina cabinet manufacturers have long been trusted across the U.S. thanks to the state’s deep heritage in woodw...

01/08/2026 | David Nguyen

Top Cabinet Manufacturers in Arizona | Best Arizona Kitchen ...

Cabinet manufacturers in Arizona have gained increasing attention as construction activity accelerates across Phoenix, T...

01/06/2026 | David Nguyen

Top Cabinet Manufacturers Indiana | Best Indiana Kitchen Cab...

Cabinet manufacturers Indiana have become increasingly relevant as contractors and developers look for dependable Midwes...

01/04/2026 | David Nguyen

Contact us

Casta is always ready to listen and answer all customers' questions