A furniture manufacturer in Vietnam offers North American contractors and cabinet brands a reliable solution for high-volume, cost-effective production. With $12 billion in exports in 2024 and growing at 8% annually, Vietnam has become a top global hub for furniture manufacturing. These factories combine European-grade automation with competitive pricing, meeting strict VOC and sustainability standards. From hotels to apartments, leading furniture manufacturers in Vietnam deliver quality, scale, and design flexibility—often at 25–40% savings over U.S. production. This blog will help you identify the right partner with clear evaluation criteria, case studies, and a practical sourcing checklist.

Table of Contents

1. Six Evaluation Criteria for Leading Vietnamese Furniture Manufacturers

Selecting the right furniture manufacturer in Vietnam is a critical decision for contractors, cabinet brands, and developers looking to balance scale, quality, and cost efficiency. Below are the six pillars every buyer should evaluate when comparing top furniture manufacturers in Vietnam and furniture made in Vietnam manufacturers.

1.1 Quality of Craftsmanship & Materials

A high‑performing furniture manufacturer in Vietnam will consistently produce components with precision and durability. Many leading factories use European CNC machinery to achieve tolerances as tight as ±0.1 mm, ensuring every panel, joint, and edge fits flawlessly.

Key quality factors include:

- Materials: FSC-certified solid wood, premium veneers, and engineered boards for stability and long life.

- Durability Tests: Resistance to scratches, moisture, and UV exposure to maintain appearance over the years of use.

- Edge Protection: PUR hot‑melt edge banding that seals against moisture and prevents peeling over time.

1.2 Manufacturing Technology & Automation

The most efficient furniture manufacturers in Vietnam leverage high levels of automation to ensure consistent quality and scalable production. Advanced technology not only speeds up output but also reduces errors and waste.

Typical investments include:

- CNC Routers (HOMAG, Biesse, SCM) for precise cutting.

- Automated Edge-Banding using PUR hot‑melt or laser technology for seamless finishes.

- In‑Line Sanding & Finishing to deliver uniform surface quality across every unit.

1.3 Certifications & Health Safety

Certifications are non‑negotiable when selecting a furniture made in Vietnam manufacturer for North American projects. They ensure compliance with environmental, safety, and quality standards.

Essential certifications:

- CARB Phase 2: Formaldehyde emissions ≤ 0.05 ppm.

- FSC Mix‑Credit: Proof of responsible forestry sourcing.

- E1 European VOC Standard: Low emissions for improved indoor air quality.

Many top furniture manufacturers in Vietnam conduct both in‑house QC audits and independent third‑party inspections before shipping.

1.4 Production Capacity & Lead Times

A furniture manufacturer in Vietnam must have the capacity to meet your project demands without risking delays.

Typical ranges:

- Mid‑Size Factories: 500–1,000 kitchen sets/month — suited for smaller developments.

- High‑Capacity Plants: 1,500–2,000+ sets/month, scalable for peak season demand.

Lead times for most furniture manufacturers in Vietnam are 30–45 days for export orders, including production and ocean freight.

Learn more: Lead Times & Supply Chain Resilience: Navigating Potential Disruptions

1.5 Customization & Design Support

Customization is a key differentiator for top furniture manufacturers in Vietnam. Buyers should look for factories with strong design teams and flexible workflows.

Features to expect:

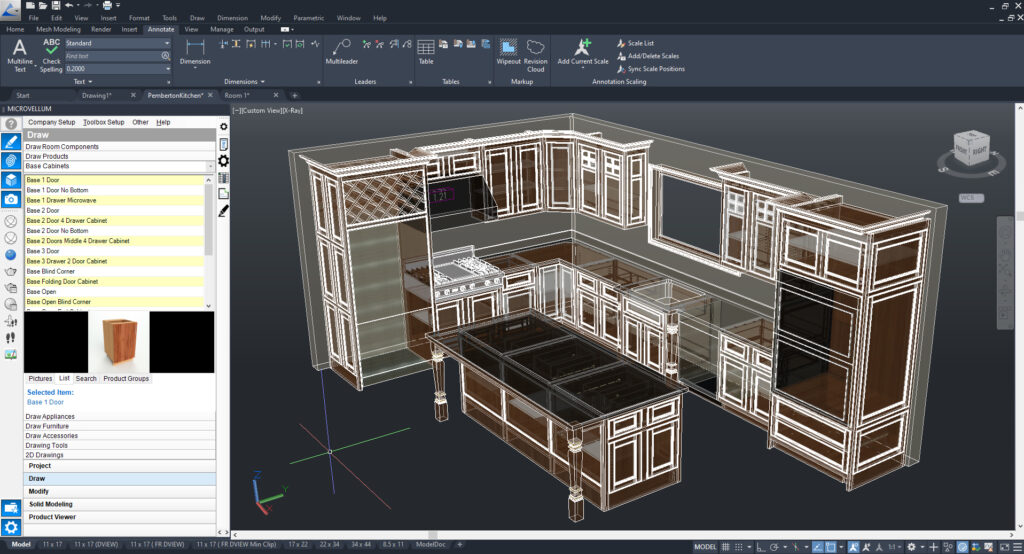

- CAD/BIM Integration for precise planning and multiple design revisions.

- Private‑Label Branding with custom doors, packaging, and documentation.

- MOQ Flexibility: Some furniture made in Vietnam manufacturers offer custom runs starting from just 20 sets.

Learn more: Best custom cabinet manufacturers

1.6 Logistics & Total Cost

A reliable furniture manufacturer in Vietnam will have a streamlined logistics process, from port-to-door delivery to U.S. customs clearance.

Advantages include:

- AD/CVD Exemption: Many Vietnam‑made products are free from AD/CVD tariffs and unaffected by trade war tariffs, lowering total landed costs.

- Cost Advantage: 25–40% savings compared to U.S. domestic production.

- Local Support: Some furniture manufacturers in Vietnam maintain U.S. service hubs for spare parts and warranty handling.

2. Casta: Benchmark Furniture Manufacturer in Vietnam

When discussing the top furniture manufacturers in Vietnam, Casta consistently ranks as one of the most trusted names for North American contractors, cabinet brands, and large‑scale developers. As a high‑capacity furniture manufacturer in Vietnam, Casta has built a reputation for blending advanced European production technology with strict quality assurance, scalable capacity, and reliable global logistics.

For buyers seeking furniture made by Vietnamese manufacturers, Casta offers a rare balance of precision, customization, and cost efficiency — making it a preferred choice for demanding multi‑unit residential, hospitality, and commercial projects.

2.1 Company Overview

Casta operates a 100,000 m² state‑of‑the‑art facility in Ho Chi Minh City, strategically located near Vietnam’s busiest export ports. This allows for faster container loading, reduced inland transport costs, and more efficient shipment scheduling to North America. The plant is designed to handle both high‑volume standard production and complex, fully customized OEM projects for hotel chains, apartment complexes, and luxury developments.

- Automation Level: 90% automated production lines, with every stage — from CNC cutting to final finishing — digitally integrated for real‑time monitoring and consistent output.

- U.S. Presence: Sales and service offices in California, Texas, and New York ensure smooth communication, sample handling, order tracking, and after‑sales support for North American clients.

- Export Focus: Over 80% of production is exported, with the U.S. as the main market, supported by a dedicated logistics team managing port‑to‑door delivery and customs processes.

2.2 Excellence Across Evaluation Criteria

Casta meets or exceeds all six key criteria for selecting a furniture manufacturer in Vietnam, making it a benchmark in the industry:

- Craftsmanship: All panels are cut with ±0.1 mm precision on advanced CNC machinery. PUR hot‑melt edge sealing enhances moisture resistance and durability — essential for high‑traffic, multi‑family housing and coastal projects.

- Technology: Equipped with HOMAG and Biesse CNC routers, laser edgebanders, and automated sanding systems, ensuring consistent finishes across thousands of units.

- Certifications: Fully compliant with CARB Phase 2, FSC Mix‑Credit, and E1 European VOC standards — critical for U.S. market health and environmental regulations.

- Capacity: Current output of 2,000 kitchen sets per month, with scalability to 3,000 sets for peak demand periods.

- Customization: Offers MOQs as low as 20 sets for custom projects. Provides 3–5 CAD/BIM design iterations pre‑production to ensure every detail meets client specifications.

- Logistics: Port‑to‑door delivery in 30–45 days, including customs clearance. Eligible for AD/CVD duty exemptions, cutting total landed costs for U.S. buyers by up to 40% compared to domestic manufacturing.

Learn more: Casta’s ideal custom cabinets

2.3 Case Studies

Gravity – Columbus, OH

- Order: 234 kitchen sets for a large apartment complex.

- Lead Time: 38 days port‑to‑door.

- Results: Achieved 28% cost savings compared to U.S. production, with a defect rate under 1%. Reinforces Casta’s standing as a furniture manufacturer in Vietnam delivering both cost efficiency and quality consistency.

Ridgegate Station – Lone Tree, CO

- Order: 269 kitchen sets for a high‑density residential project.

- Lead Time: 42 days total, including customs.

- Results: Zero rework required, with high tenant satisfaction due to uniform finishes and precise installations — a hallmark of a top‑tier furniture manufacturer in Vietnam.

CityView Towers – Chicago, IL

- Order: 500 kitchen sets for a major urban high‑rise.

- Lead Time: 40 days from factory dispatch to site delivery.

- Results: Delivered a 30% landed‑cost advantage while ensuring consistent quality across all units. Demonstrated the scalability and reliability that distinguish Casta from other furniture made in Vietnam manufacturers.

Learn more: Casta’s outstanding international projects

4. ROI & Total Cost Analysis

Partnering with a reputable furniture manufacturer in Vietnam can have a transformative impact on project profitability for North American contractors, cabinet brands, and large‑scale developers. The value goes well beyond the initial price per unit — combining lower material and production costs, reduced installation labor, and minimal post‑completion maintenance. This holistic advantage results in a measurable and sustainable boost to return on investment when compared to sourcing from domestic suppliers.

4.1 Material & Production Savings

Collaborating with furniture manufacturers in Vietnam can lower per‑unit costs by 25–40% without compromising build quality. These savings are driven by Vietnam’s competitive labor market, high‑capacity automated production lines, and trade benefits such as AD/CVD duty exemptions.

For major multi‑unit projects, this pricing advantage can easily result in hundreds of thousands of dollars in cost reductions over the course of a single development.

4.2 Labor Savings

Many furniture made in Vietnam manufacturers offer precision‑engineered RTA (ready‑to‑assemble) kits that are optimized for quick, error‑free installation. These systems can cut on‑site labor requirements by 15–20%, allowing installation crews to complete more units in less time.

This faster turnaround is particularly beneficial in multi‑family housing, hospitality developments, and high‑rise projects where every day saved reduces holding and operational costs.

4.3 Maintenance Savings

A high‑performing furniture manufacturer in Vietnam like Casta maintains defect rates of less than 1% due to advanced European CNC precision and rigorous in‑line quality control. Fewer defects mean fewer callbacks, warranty claims, and costly schedule disruptions — ensuring smoother handovers and happier end users.

Example ROI Calculation:

- 100 kitchens at U.S. domestic cost = $500,000

- Vietnam sourcing at 30% savings = $350,000

- Total Direct Savings = $150,000

These figures don’t even include indirect benefits such as faster installations, reduced replacement part needs, and the ability to reinvest saved budget into upgraded finishes, premium hardware, or additional units. For any business evaluating international sourcing, the ROI from selecting the right furniture manufacturer in Vietnam is not just immediate — it compounds over future projects, improving both margins and competitive positioning in the market.

Learn more: Why Vietnam Became a Top Supplier of Premium Furniture to America?

5. Buyer’s Checklist for Selecting a Furniture Manufacturer in Vietnam

Selecting the right furniture manufacturer in Vietnam is a decision that can influence your project’s cost efficiency, delivery timeline, and long‑term quality outcomes. This process is about more than just finding the lowest bid — it’s about ensuring your supplier has the production capacity, technical expertise, and logistical capabilities to meet the demands of complex, large‑scale projects. The most successful sourcing strategies involve partnering with top furniture manufacturers in Vietnam that have a strong track record in the North American market and the ability to adapt to your specific requirements.

Below is a detailed checklist to guide your selection:

5.1 Match Project Scale with Factory Capacity

Confirm that your chosen furniture manufacturer in Vietnam can handle your required output without delays or quality drops. For large multi‑family, hospitality, or commercial projects, prioritize furniture manufacturers in Vietnam with the proven ability to produce 1,500–3,000 sets per month while maintaining consistent finishes and precision standards.

5.2 Ensure Lead Time Fits Your Construction Schedule

A dependable furniture manufacturer in Vietnam should provide clear, realistic port‑to‑door timelines — typically 30–45 days for export orders — and have contingency plans in place for peak production seasons or rush orders. Delays can be costly, so reliability in scheduling is critical.

5.3 Verify Certifications

Always demand verifiable certifications such as CARB Phase 2 (low formaldehyde emissions), FSC Mix‑Credit (responsible forestry sourcing), and E1 VOC standards (European low‑emission compliance). These credentials confirm your furniture made in Vietnam manufacturer meets North American environmental and safety standards — crucial for both compliance and brand reputation.

5.4 Check Customization Workflow & MOQ Flexibility

Review the factory’s design process, including how many CAD/BIM iterations are included before production approval, and confirm the minimum order quantity (MOQ). Many top furniture manufacturers in Vietnam offer MOQs as low as 20 sets for custom projects, giving you the flexibility to test designs and finishes before scaling up.

5.5 Review Logistics Handling & Duty Exemptions

The best furniture manufacturers in Vietnam manage end‑to‑end logistics, including port‑to‑door shipping and customs clearance. Many qualify for AD/CVD duty exemptions for U.S. clients, reducing total landed costs by up to 40% compared to domestic production.

5.6 Request Samples, CAD/BIM Files, and Pilot Runs

Before committing to a large order, ask your selected furniture manufacturer in Vietnam for product samples, detailed technical drawings, and a pilot production run. This ensures that materials, dimensions, finishes, and assembly processes meet your expectations before full‑scale manufacturing begins.

By following this checklist, you’ll be equipped to choose a furniture manufacturer in Vietnam that not only meets your immediate project needs but also becomes a long‑term, strategic sourcing partner. The right choice will deliver scalable production, certified quality, competitive costs, and dependable logistics — ensuring success across current and future projects.

Learn more: Sourcing Cabinets and Furniture from Vietnam: Your Ultimate Guide

6. Vietnam as a Strategic Sourcing Advantage for North American Projects

Partnering with a Vietnamese furniture manufacturer offers North American contractors, cabinet brands, and developers the ability to scale efficiently while maintaining certified quality and competitive pricing. With proven leaders like Casta setting industry standards, the top furniture manufacturers in Vietnam demonstrate that furniture made in Vietnam manufacturers can consistently outperform domestic suppliers in cost efficiency, production precision, customization options, and on-time delivery. For large-scale projects — from multi-family housing to hospitality fit-outs — choosing the right furniture manufacturer in Vietnam is not just a cost-saving decision, but a strategic move to ensure quality, compliance, and long-term sourcing reliability.

7. Frequently Asked Questions (FAQ)

What’s the lowest MOQ for custom furniture lines?

Are Vietnam-made cabinets exempt from AD/CVD duties?

How long is port-to-door lead time?

Can I get CAD/BIM files before production?

What certifications should I look for?

Top Cabinet Manufacturers in Florida: A Capability-Based Buy...

Cabinet manufacturers in Florida play a critical role in one of the fastest-growing construction markets in North Americ...

01/10/2026 | David Nguyen

Top North Carolina Cabinet Manufacturers | Best NC Kitchen ...

North Carolina cabinet manufacturers have long been trusted across the U.S. thanks to the state’s deep heritage in woodw...

01/08/2026 | David Nguyen

Top Cabinet Manufacturers in Arizona | Best Arizona Kitchen ...

Cabinet manufacturers in Arizona have gained increasing attention as construction activity accelerates across Phoenix, T...

01/06/2026 | David Nguyen

Top Cabinet Manufacturers Indiana | Best Indiana Kitchen Cab...

Cabinet manufacturers Indiana have become increasingly relevant as contractors and developers look for dependable Midwes...

01/04/2026 | David Nguyen

Contact us

Casta is always ready to listen and answer all customers' questions