In recent years, growing awareness of indoor air quality and its profound impact on human health has spurred a significant shift toward healthier building materials. Among these, low VOC cabinets have emerged as a critical choice for environmentally-conscious contractors, cabinet brands, and homeowners. These cabinets reduce harmful chemical emissions, contributing to cleaner air and safer living environments, especially in homes and workplaces where indoor air quality plays a crucial role in health.

Table of Contents

1. What are the VOC Cabinets?

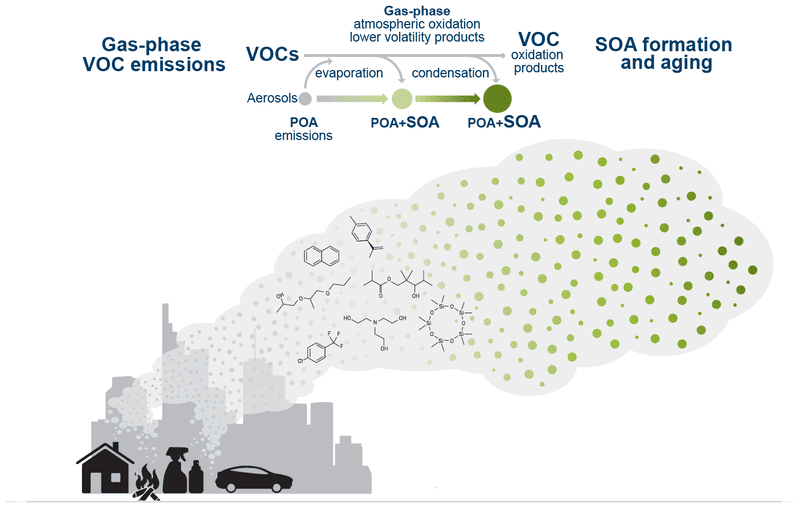

VOCs, or Volatile Organic Compounds, are chemicals that evaporate at room temperature, commonly found in paints, adhesives, and building materials. Traditional cabinets, made from materials like plywood, MDF (medium-density fiberboard), and particleboard, can off-gas VOCs over time. This process, called off-gassing, releases pollutants into the air, which may cause respiratory problems, headaches, and even long-term health issues like cancer.

As the demand for healthier and more eco-friendly building solutions increases, contractors and cabinet brands are turning to low VOC cabinets to meet these needs. This guide explores why these cabinets are essential, how they can improve your projects, and what you need to know when choosing them.

2. What Are VOCs and Why Are They Harmful?

VOCs are carbon-based chemicals commonly found in paints, stains, varnishes, and adhesives used in cabinet manufacturing. When these chemicals evaporate into the air, they can cause indoor air pollution, leading to various health problems. Some of the most harmful VOCs include formaldehyde, benzene, and toluene, which are prevalent in many conventional building materials.

The off-gassing of these chemicals can continue for years, especially in closed environments with poor ventilation. Prolonged exposure to high levels of VOCs can lead to chronic health issues such as asthma, allergies, and other respiratory conditions. As more studies reveal the dangers of VOCs, there’s a growing push to minimize their use in building materials, particularly in spaces like kitchens and bathrooms, where families spend much of their time.

By choosing low VOC kitchen cabinets, contractors and brands can significantly reduce these harmful emissions, offering a safer, healthier alternative. Low VOC cabinets are made using formaldehyde-free adhesives, water-based finishes, and sustainable materials that minimize harmful off-gassing.

3. The Impact of Low VOC Standards in the U.S. and Canada

The shift toward low VOC cabinets in North America is largely driven by stricter regulations from environmental agencies like the California Air Resources Board (CARB) and the Environmental Protection Agency (EPA). These agencies set stringent limits on the amount of formaldehyde and other VOCs that can be emitted from building products.

Learn more: What is CARB Compliance? Why is It Important?

For instance, CARB Phase 2 regulations require that formaldehyde emissions from composite wood products do not exceed 0.05 parts per million (ppm). This standard is widely regarded as the benchmark for low VOC compliance in the U.S., and many products that meet CARB Phase 2 standards also comply with international standards, such as the European E1 Standard.

By adopting low VOC cabinets, contractors can align their projects with LEED (Leadership in Energy and Environmental Design) certification requirements. LEED certification is awarded to buildings that prioritize sustainability, energy efficiency, and health-conscious materials. In fact, LEED-certified buildings can add up to 8-12% more value to a property, according to the U.S. Green Building Council.

Learn more: Cabinet Certification - Setting the Gold Standard for Quality and Reliability

4. Types of Low VOC Cabinets

4.1 Low VOC Kitchen Cabinets

In a space where families gather and spend significant time, it’s crucial to prioritize low VOC kitchen cabinets. Traditional cabinets, especially in kitchens, often trap VOCs, releasing them slowly over time, affecting the air quality. Kitchens are particularly vulnerable because cooking can produce heat and moisture, which can exacerbate off-gassing.

Low VOC cabinets are typically made from materials like formaldehyde-free plywood, eco-friendly MDF, and sustainable hardwoods. Water-based finishes and low-VOC adhesives ensure that these kitchen cabinets contribute to a healthier indoor environment while still offering durability and aesthetic appeal. Contractors working on kitchen projects can assure homeowners that their cabinets are free from harmful emissions, contributing to a safer living environment.

Learn more: Everything You Need to Know About Formaldehyde-Free Cabinets

4.2 Low VOC Cabinet Paint Options

Low VOC cabinet paint is another critical component of environmentally friendly cabinetry. Conventional paints can release high levels of VOCs for years after application, affecting indoor air quality long after the project is complete. Water-based, zero-VOC paints, in contrast, contain fewer than 50 grams of VOCs per liter, compared to up to 300 grams per liter found in traditional oil-based paints.

Low VOC paints and finishes have become more durable in recent years, rivaling their traditional counterparts in terms of performance. While they dry more quickly and are easier to clean up, they also have lower odor levels, making them more pleasant to work with during installation. Offering low VOC cabinet paint options is an easy way for contractors to boost their projects’ sustainability while ensuring clients’ homes are safe and healthy.

4.3 Cabinets with Low VOC Materials

Cabinets that use low VOC materials are an integral part of creating healthy, sustainable spaces. Common materials include:

- Formaldehyde-Free Plywood: Traditional plywood often contains formaldehyde-based adhesives, but newer, eco-friendly versions eliminate this harmful chemical without sacrificing durability.

- Sustainable MDF: Engineered wood products like MDF can now be made with adhesives that meet low VOC standards, offering a cost-effective and durable alternative to solid wood.

- FSC-Certified Hardwood: The Forest Stewardship Council (FSC) certifies that the wood used in these cabinets is sustainably harvested, ensuring that both environmental and health standards are met.

Here’s a comparison of low VOC cabinet materials:

| Material | VOC Emissions | Durability | Cost |

| Formaldehyde-Free Plywood | Very Low | High | Moderate |

| Sustainable MDF | Low | Moderate | Affordable |

| FSC-Certified Hardwood | Very Low | Very High | High |

5. Benefits of Low VOC Cabinets for Contractors and Cabinet Brands

5.1 Health and Safety: Meeting Consumer Demands

As consumers become more educated about the impact of indoor air quality on their health, they are actively seeking healthier options. Offering low VOC cabinets positions contractors and brands as leaders in this growing market. For example, a recent Houzz survey found that 35% of homeowners opted for low VOC materials in their kitchen renovations in 2023, citing health concerns as a primary factor.

By offering cabinets with low VOC emissions, contractors and cabinet brands can cater to these health-conscious consumers while reducing liability risks associated with poor indoor air quality. This proactive approach helps brands differentiate themselves from competitors, boosting long-term customer loyalty.

5.2 Environmental Impact: Sustainability and LEED Points

Low VOC cabinets are also a significant asset when it comes to achieving LEED certification. Green building practices are no longer just a trend—they’re becoming the norm. Buildings designed with sustainability in mind can command higher prices, with LEED-certified properties seeing 8-12% higher value on the market, according to the U.S. Green Building Council.

By using low VOC materials, contractors can accrue points toward LEED certification, contributing to both environmental sustainability and market appeal.

5.3 Cost and Long-Term Value

While low VOC cabinets may come with a slightly higher upfront cost due to the more expensive materials and manufacturing processes, the long-term benefits outweigh these initial expenses. Homes featuring low VOC materials, including cabinetry, often sell for 5-10% higher than homes with conventional materials. The health benefits, combined with the eco-friendly appeal, provide a strong return on investment.

Contractors can also emphasize the long-term cost savings associated with reduced healthcare risks and fewer complaints about off-gassing, making low VOC cabinets an economically sound choice in the long run.

6. Key Considerations When Choosing Low VOC Cabinets

6.1 Certifications and Standards to Ensure Low VOC

When selecting low VOC cabinets, it’s important to verify their certification to ensure compliance with health and environmental standards. Some of the most recognized certifications include:

- CARB Phase 2: Ensures compliance with formaldehyde emission standards.

- FSC (Forest Stewardship Council): Guarantees sustainably sourced wood.

- GREENGUARD: Certifies that products are tested for chemical emissions and are safe for indoor air quality.

Here’s a quick reference chart for these certifications:

| Certification | Focus | Applicable to |

| CARB Phase 2 | Formaldehyde Emissions | Composite Wood |

| FSC (Forest Stewardship Council) | Sustainable Sourcing | Wood Materials |

| GREENGUARD | Chemical Emissions Testing | Finished Cabinets |

6.2 Supplier Selection and Materials

Partnering with reputable suppliers that prioritize low VOC materials is crucial for contractors and cabinet brands aiming to offer eco-friendly solutions. Reliable suppliers should provide documentation on their manufacturing processes and compliance with VOC standards.

At Casta Cabinetry, we offer fully customizable low VOC cabinets designed to meet North American standards. Our materials are sourced responsibly, and we adhere to strict health and safety guidelines, ensuring that our cabinets not only meet but exceed expectations.

7. Casta Cabinetry: Low VOC Cabinet Solutions for Contractors and Brands

7.1 Manufacturing Process and Certifications

At Casta Cabinetry, we take pride in producing cabinets that are not only stylish and functional but also safe for your clients’ health. All of our products are manufactured using state-of-the-art European machinery, and we adhere to CARB Phase 2, FSC, and E1 emission standards. This ensures that every cabinet we produce is free from harmful VOCs, making them ideal for modern, health-conscious spaces.

7.2 Customization and Design Flexibility

Our low VOC cabinets can be fully customized to fit the unique requirements of any project. Whether you’re working on a residential renovation or a commercial build, Casta Cabinetry offers endless options for low VOC cabinet paint, finishes, and materials. Choose from a range of eco-friendly paints and sustainably sourced wood to create the perfect design for your clients.

Learn more: Casta’s Projects

7.3 Delivery Support

Casta Cabinetry also understands the importance of meeting project timelines. That’s why we offer comprehensive delivery support, ensuring that our cabinets arrive on time and in perfect condition, allowing contractors and cabinet brands to meet their deadlines without compromise.

8. Trends in Low VOC Cabinets for the North American Market

The market for low VOC cabinets in North America is growing as more homeowners and builders become aware of the benefits of healthy indoor environments. Trends indicate an increase in the use of formaldehyde-free MDF, nano-tech coatings, and bio-based adhesives that minimize VOC emissions. These innovations allow cabinet manufacturers to produce durable, stylish products without compromising air quality.

According to a report by Houzz, 30% of kitchen remodels now include low VOC materials, with more homeowners willing to invest in eco-friendly solutions. As consumer awareness continues to grow, the demand for low VOC cabinets will only increase, driving innovation and sustainability in the cabinetry industry.

9. FAQ

What are low VOC cabinets?

Are low VOC cabinets as durable as traditional cabinets?

What certifications should I look for in low VOC cabinets?

Low VOC cabinets represent the future of healthy, sustainable living spaces. As awareness around indoor air quality continues to rise, contractors and cabinet brands that prioritize low VOC options will stand out in the market. These cabinets not only offer health benefits by reducing harmful emissions but also contribute to environmental sustainability.

Casta Cabinetry offers customizable low VOC cabinet solutions designed to meet the demands of modern projects. By choosing low VOC options, you ensure that your clients enjoy both style and safety, all while promoting a healthier future.

Related articles:

Top Cabinet Manufacturers in Florida: A Capability-Based Buy...

Cabinet manufacturers in Florida play a critical role in one of the fastest-growing construction markets in North Americ...

01/10/2026 | David Nguyen

Top North Carolina Cabinet Manufacturers | Best NC Kitchen ...

North Carolina cabinet manufacturers have long been trusted across the U.S. thanks to the state’s deep heritage in woodw...

01/08/2026 | David Nguyen

Top Cabinet Manufacturers in Arizona | Best Arizona Kitchen ...

Cabinet manufacturers in Arizona have gained increasing attention as construction activity accelerates across Phoenix, T...

01/06/2026 | David Nguyen

Top Cabinet Manufacturers Indiana | Best Indiana Kitchen Cab...

Cabinet manufacturers Indiana have become increasingly relevant as contractors and developers look for dependable Midwes...

01/04/2026 | David Nguyen

Contact us

Casta is always ready to listen and answer all customers' questions