Choosing the right kitchen cabinet materials can make or break a project’s success. Material selection influences durability, moisture resistance, finish options, cost-efficiency, and even assembly compatibility. Contractors, cabinet brands, and furniture companies sourcing in bulk must avoid overpaying for specs they don’t need or underestimating performance requirements for high-traffic or commercial applications. In this guide, we cover five primary types of kitchen cabinet materials, their sub-types, pros and cons, certifications, and real-world use cases—so you can specify the best material for kitchen cabinets.

Table of Contents

1. The 5 Main Types of Kitchen Cabinet Materials and Their Sub-Types

1.1 Plywood

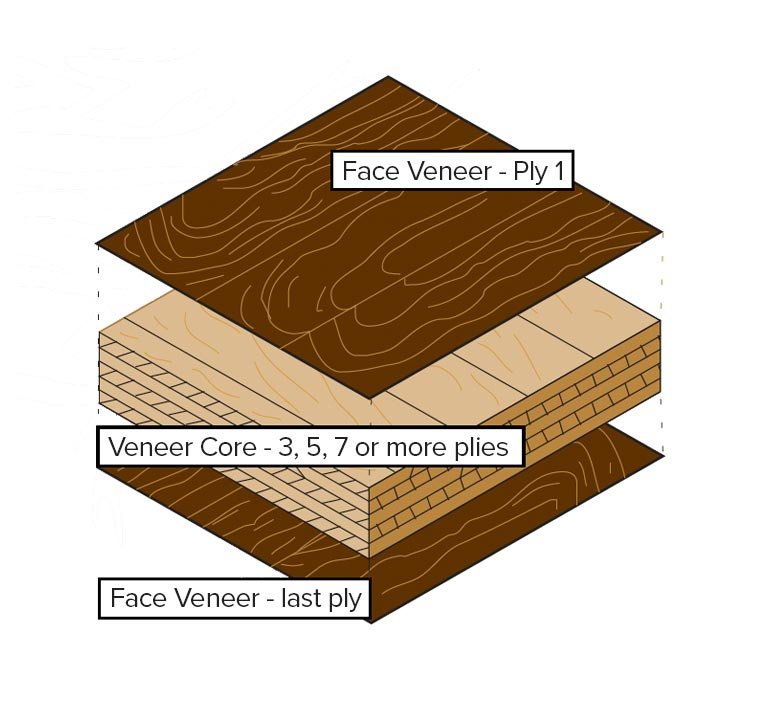

Plywood remains one of the most popular types of kitchen cabinet materials thanks to its exceptional strength-to-weight ratio and resistance to warping. It’s constructed by cross-laying thin wood veneers—often 1–2 mm thick—at 90° grain orientation, then bonding them under heat and pressure with waterproof adhesives.

Key Technical Specs:

- Thicknesses Available: ¼″ (6 mm), ½″ (12 mm), ¾″ (18 mm)

- Typical Densities: 550–700 kg/m³

- Core Types: Birch (constant thickness), radiata pine (cost-effective), hardwood (premium)

- Edge Treatment: Requires veneer edge banding or solid wood trim

Performance and Use Cases:

- Load Capacity: Shelves support up to 80 lbs per linear foot when braced properly.

- Moisture Resistance: Exterior-grade (BS 1088) plywood can withstand occasional splashes if sealed.

- Finish Options: Paint, veneer, thermofoil, or lacquer.

| Sub-Type | Description | Best For |

| 3-Ply | Three alternating veneer layers | Small cabinet boxes, under-sink enclosures |

| 5-Ply | Five veneers for uniform strength | Standard base/upper cabinets |

| Multi-Ply (7+ layers) | Premium build for maximum stability | Heavy-duty kitchen islands, commercial RTA |

Pros:

- Superior screw-holding strength (50 % more than particle board)

- Excellent dimensional stability under temperature changes

- Holds up well in high-use environments

Cons:

- Premium grades can cost 20–30 % more than MDF

- Visible edges require careful finishing

Learn more: Difference between mdf and mfc vs plywood vs hdf

1.2 Blockboard

Blockboard is engineered by edge-gluing 15–30 mm wide softwood strips into a solid core and sandwiching between hardwood veneers. It delivers flat panels with reduced risk of split edges.

Key Technical Specs:

- Panel Thicknesses: 12 mm, 18 mm, 25 mm

- Core Density: 350–400 kg/m³ (softwood)

- Veneer Faces: Oak, maple, birch—0.6–1 mm

Performance and Use Cases:

- Span Capacity: Ideal for door heights up to 3 ft without sagging.

- Weight Savings: Up to 25 % lighter than equivalent plywood.

- Finishing: Requires sanding and sealing before paint or laminate.

| Sub-Type | Description | Best For |

| Standard Blockboard | Untreated core + veneer faces | Pantry doors, tall cabinets |

| Moisture-Resistant Blockboard | Core treated with melamine resin | Coastal kitchens, laundry rooms |

Pros:

- Lighter panels simplify installation on tall frames

- Reduced material waste—core strips are milled from offcuts

Cons:

- Veneer peeling if improperly bonded

- Limited option for invisible joints

Learn more: Blockboard - Best Choice for Cabinets

1.3 MDF (Medium-Density Fiberboard)

MDF is made by blending wood fibers (~0.1 mm) with urea-formaldehyde resin, then pressing at 850–1,000 psi. Its uniform density and smoothness make it a go-to among types of kitchen cabinet materials for painted finishes.

Key Technical Specs:

- Densities: 650–800 kg/m³

- Sheet Sizes: 4′×8′, 5′×10′

- Thicknesses: 3 mm–32 mm

Performance and Use Cases:

- Edge Profiling: CNC-machinable for intricate door styles (e.g., Shaker, raised panels).

- Surface Finish: Virtually void-free—optimal for high-gloss paints.

- Weight: 30–40 % heavier than plywood per square foot.

| Sub-Type | Description | Best For |

| Standard MDF | Economy grade, smooth core | Painted budget cabinetry |

| Moisture-Resistant MDF (MR) | Wax or resin-treated core | Bathroom vanities, coastal cabinets |

| High-Density Fiberboard (HDF) | Higher compressive strength (up to 900 kg/m³) | Detailed mouldings, sliding doors |

Pros:

- No veneer defects—consistent finish across large panels

- Lower material cost than plywood

Cons:

- Requires full sealing against moisture—edges particularly vulnerable

- Heavier panels increase strain on hinges

Learn more: What is mdf cabinets?

1.4 Particle Board (Chipboard)

Particle board uses wood chips and sawdust bonded under low pressure. It’s the most cost-effective of the types of kitchen cabinet materials, but its performance is best reserved for budget or concealed applications.

Key Technical Specs:

- Density Range: 600–800 kg/m³

- Thickness Range: 12 mm–38 mm

- Face Treatments: Melamine, laminate, foil

Performance and Use Cases:

- Flat-Pack (RTA): Ideal for ready-to-assemble boxes that ship economically.

- Edge Finishing: Edgeband tape essential to prevent moisture ingress.

- Load Capacity: Holds ~30 lbs per shelf; best for light-duty use.

| Sub-Type | Description | Best For |

| Standard Particle Board | Basic density, no moisture treatment | Entry-level base cabinets |

| Moisture-Resistant PB | Wax-impregnated core | Low-budget bathroom cabinets |

| Veneered Particle Board | Real wood veneer facings | Economical wood-grain appearance |

Pros:

- Lowest material cost (~40 % below plywood)

- Simplified machine-cut processing

Cons:

- Susceptible to swelling—avoid under-sink areas

- Lower screw retention—use confirmat screws

Learn more: Are particle board cabinets good?

1.5 Hardboard (High-Density Fiberboard Sheets)

Hardboard, pressed at very high pressures (up to 2,200 psi), creates a thin, dense panel—usually 1–4 mm thick—used non-structurally in cabinets.

Key Technical Specs:

- Thickness: 1.5 mm, 3 mm, 4 mm

- Density: ~900 kg/m³

- Face Finish: Smooth, amenable to laminates

Performance and Use Cases:

- Back Panels: Secured by grooves in the cabinet carcass for seamless look.

- Drawer Bottoms: Provides stiff, stable floor for smooth gliding.

| Sub-Type | Description | Best For |

| Standard Hardboard | Uncoated, raw backer | Sealed cabinet backs, shelving |

| Laminated Hardboard | Factory-bonded finish | Exposed interior panels |

Pros:

- Inexpensive back material keeps overall cost down

- Very uniform thickness—easy to line up

Cons:

- Not suitable for weight support

- Prone to delamination if edges aren’t sealed

By diving deeper into each of these types of kitchen cabinet materials, you can match the right substrate to your project’s structural needs, finish requirements, and budget—ensuring a kitchen that looks great and lasts for decades.

2. Material Performance Comparison Table

To help you evaluate the types of kitchen cabinet materials side-by-side, the table below breaks down key performance metrics—strength, moisture resistance, cost efficiency, finish quality, structural use, and flat-pack suitability. This comparison supports informed decisions on which material best fits your project’s demands and budget.

| Material Type | Strength | Moisture Resistance | Cost Efficiency | Finish Quality | Structural Use | Flat-Pack Suitability |

| 3-Ply Plywood | Medium | Moderate | Medium | Good | Light-duty boxes | Yes |

| 5-Ply Plywood | High | Good | Medium | Good | Cabinet boxes | Yes |

| Multi-Ply Plywood | Very High | High | Low | Excellent | Premium cabinetry | No |

| Blockboard | Medium | Moderate–High | Medium | Veneer only | Tall panels | Yes |

| Standard MDF | Medium | Low | High | Paint-ready | Doors, panels | Yes |

| MR MDF | Medium | Moderate | Medium | Paint-ready | Wet-area uses | Yes |

| HDF | High | Low–Moderate | Med–High | Paint/detail | Doors | Yes |

| Std Particle Board | Low | Low | Very High | Melamine veneer | Low-cost boxes | Yes |

| MR Particle Board | Low–Med | Moderate | Medium | Melamine veneer | Wet-area boxes | Yes |

| Veneered PB | Low–Med | Low | Medium | Wood-look veneer | Budget cabinetry | Yes |

| Hardboard | Low | Low | Very High | Low | Back panels | Yes |

By reviewing this performance matrix of the main types of kitchen cabinet materials, you can pinpoint which substrate aligns with your design goals and project constraints:

- Plywood variants (3-Ply, 5-Ply, Multi-Ply) offer progressively greater strength and moisture resistance, though cost increases with layer count.

- Blockboard delivers a lightweight alternative for tall doors while still accommodating flat-pack assembly.

- Engineered fibreboards (MDF, MR MDF, HDF) excel in finish quality—ideal for painted or intricately profiled doors—and vary in moisture tolerance.

- Particle board options prioritize cost efficiency, especially in entry-level or RTA cabinetry, but require edge banding and careful moisture management.

- Hardboard remains the go-to for inexpensive, non-load-bearing back panels and drawer bottoms.

Use this detailed comparison to guide your choice among the types of kitchen cabinet materials that best balance performance, aesthetics, and budget for your next build.

3. How to Choose the Right Material by Project Type

Selecting among the various types of kitchen cabinet materials depends heavily on your buyer’s needs, project scale, and performance priorities. Below are expanded recommendations for each buyer type, including why each material shines for that segment and how it aligns with common project requirements.

3.1 Contractors (Bulk Purchases)

Goal: Durable and cost-effective cabinets that are quick to build and consistent across high-volume installs.

Recommended Materials:

- 5-Ply Plywood: Excellent strength and screw-holding; works well in load-bearing cabinetry and wet areas.

- Moisture-Resistant (MR) MDF: Holds paint well, resists humidity better than standard MDF, ideal for budget-friendly kitchens.

- Veneered Particle Board: Natural wood veneer aesthetics with low-cost particle board core for mass deployment.

Key Tips:

- Verify CARB Phase 2 and E1 certifications for safety compliance.

- Reinforce weaker cores (e.g., particle board) using dowel joints or confirmat screws to reduce return rates.

3.2 Custom Cabinet Brands

Goal: Premium finishes, structural integrity, and customization options that reinforce your brand image.

Recommended Materials:

- Multi-Ply Plywood: Stable for custom joinery and luxury wood veneer overlays.

- HDF (High-Density Fiberboard): Ideal for intricate CNC profiles, sharp corners, and smooth paint application.

- Veneered Blockboard: Lightweight with great span support—suited for large doors and vertical panels.

Key Tips:

- Choose FSC-certified cores and veneers to build a sustainable brand story.

- Pre-seal cut edges for moisture protection before applying finishes.

Learn more: Leading kitchen cabinet manufacturers

3.3 Retailers (Budget SKUs)

Goal: Scalable, low-cost, flat-packable materials with fast assembly for warehouse distribution.

Recommended Materials:

- Standard MDF: Smooth, stable core for paint or foil; performs well in high-speed production lines.

- Melamine-Coated Particle Board: Pre-finished surface cuts down on labor; available in modern colorways.

Key Tips:

- Ensure color-matched edge banding to elevate product perception.

- Bundle with hardware and clear instructions to reduce after-sale service costs.

3.4 Luxury Builders

Goal: High-end detailing, material depth, and long-lasting structure for top-tier residential or hospitality projects.

Recommended Materials:

- Solid Wood (Maple, Oak, Walnut): Natural textures and prestige; accepts stains and finishes beautifully.

- Multi-Ply Plywood with Veneer: Blends the strength of engineered wood with a natural wood appearance.

- Painted HDF: Smooth, defect-free surface for matte or gloss finishes on high-detail profiles.

Key Tips:

- Use zero-VOC finishes and formaldehyde-free substrates to meet indoor air-quality standards.

- Apply frame-and-panel construction to stabilize solid wood door panels.

3.5 Multi-Family Developers

Goal: Fast-to-install, budget-efficient cabinets that can be easily replaced or replicated across units.

Recommended Materials:

- RTA MDF: Pre-cut and pre-drilled for easy on-site assembly with minimal tooling.

- MR Particle Board: Offers moisture resistance with a lower cost than plywood.

- Standard Particle Board: Useful for short-term units or economy-grade builds.

Key Tips:

- Confirm all components are properly edge-sealed to prevent water damage in storage or transit.

- Request flat-pack packaging optimized for container shipments.

3.6 Common Mistakes When Choosing Kitchen Cabinet Materials

Avoid these pitfalls across the various types of kitchen cabinet materials, and implement the accompanying solutions to ensure durable, high-quality installations:

- Prioritizing Lowest Cost Alone

- Mistake: Selecting the cheapest particle board to cut material costs.

- Consequence: Warping, finish failures, and high warranty claims.

- Solution: Balance upfront savings with longer-term durability by specifying MR-treated or veneered options and validating load-capacity ratings.

- Skipping CARB/E1 & FSC Certification Checks

- Mistake: Assuming all engineered boards meet emissions and sustainability standards.

- Consequence: Regulatory delays, fines, and import rejections in key markets.

- Solution: Require mill test reports for CARB Phase 2, E1, and FSC certifications before purchase.

- Ignoring Moisture Resistance Needs

- Mistake: Using standard MDF or particle board in humid or wet-area kitchens.

- Consequence: Swelling, delamination, and peeling of veneers or laminates.

- Solution: Specify MR-MDF, MR-PB, or exterior-grade plywood in splash zones and always seal cut edges.

- Using Non-CNC-Compatible Substrates

- Mistake: Choosing low-grade particle board for precision-machined profiles.

- Consequence: Poor cut quality, chipped edges, and production delays.

- Solution: Reserve MDF or HDF for CNC profiling; test any new substrate in a small production run.

- Mismatching Finish and Substrate

- Mistake: Applying high-gloss paint directly onto unsealed plywood or blockboard.

- Consequence: Paint cracking, veneer blow-off, or visible seam telegraphing.

- Solution: Match finish systems to substrates—use primer/sealer coats on bare wood and pressure-sensitive adhesives for thermofoil on MDF.

Learn more: The Ultimate Guide to Modern Design Kitchen Cabinets

By understanding and addressing these common errors, you’ll make the most of the full range of types of kitchen cabinet materials—ensuring projects that look great, perform reliably, and satisfy clients across every segment.

4. Casta Cabinetry’s Material Capabilities for North American Buyers

Casta Cabinetry combines an extensive selection of types of kitchen cabinet materials with robust customization and logistics services—ensuring U.S. contractors, cabinet brands, and developers receive exactly what they need, on time and to specification.

4.1 Material Range

Casta Cabinetry offers a comprehensive supply chain and manufacturing capability that spans across all major types of kitchen cabinet materials used in the North American market. Their diverse inventory ensures that every buyer—whether focused on cost, performance, or customization—can specify the ideal material for their project scope.

They stock and fabricate across the full spectrum of types of kitchen cabinet materials, including:

- Plywood: Available in multiple constructions including 3-ply for lightweight box components, 5-ply for standard cabinet carcasses, and multi-ply plywood for premium frames and heavy-duty applications. Among the types of kitchen cabinet materials, plywood remains a top choice for its balance of strength, durability, and long-term dimensional stability.

- Blockboard: Casta offers both standard blockboard panels for tall cabinet doors and moisture-resistant (MR) blockboard specifically engineered for high-humidity kitchen environments. This material serves as a lighter alternative in the wider range of kitchen cabinet materials, particularly in tall vertical applications.

- MDF: Their inventory includes standard MDF for painted cabinet surfaces, MR MDF for added moisture resistance, and high-density fiberboard (HDF) for projects requiring CNC precision and smooth finishing. Among the types of kitchen cabinet materials, MDF and HDF are preferred for custom designs with detailed profiles.

- Particle Board: For budget-focused or flat-pack solutions, Casta provides standard particle board, MR particle board, and veneered particle board with real-wood finishes. These engineered wood panels are an essential part of affordable types of kitchen cabinet materials used in mass production for multi-family units or RTA furniture.

- Hardboard: Ideal for non-structural applications, their stock includes thin, dense hardboard sheets—both raw and laminated—used for drawer bottoms and cabinet back panels. Though less prominent, hardboard remains a functional option among specialized kitchen cabinet materials for lightweight or concealed sections.

Every board, regardless of type, undergoes strict internal testing for dimensional tolerance, bonding strength, surface consistency, and emission safety. Whether you're sourcing panels for ready-to-assemble cabinet lines or crafting custom cabinetry for high-end residential builds, Casta Cabinetry offers certified, quality-controlled types of kitchen cabinet materials tailored to your project requirements.

Learn more: Casta’s ideal custom cabinets

4.2 Certifications

To satisfy North American emissions and sustainability regulations, all of Casta Cabinetry’s types of kitchen cabinet materials meet or exceed the industry’s most recognized standards:

- CARB Phase 2 (California Air Resources Board): Ensures ultra-low formaldehyde emissions across engineered substrates like MDF, particle board, and plywood—commonly used in a wide range of types of kitchen cabinet materials specified for U.S. residential and commercial kitchens.

- FSC Mix-Credit: Verifies that wood fibers in all applicable types of kitchen cabinet materials are responsibly sourced from certified forests, supporting eco-conscious construction and LEED-aligned building projects.

- E1 (European Formaldehyde Emission Class): Sets low emission thresholds for MDF, plywood, and particle board, ensuring safer indoor air quality. E1 compliance is especially relevant when selecting types of kitchen cabinet materials for enclosed or high-traffic kitchen environments.

- JIS Four-Star (Japanese Industrial Standard): Applied to MDF, particle board, and hardboard, this rating certifies moisture resistance and formaldehyde control—two critical factors in choosing high-performance types of kitchen cabinet materials for humid climates or coastal projects.

These third-party certifications not only guarantee compliance with international safety and environmental benchmarks, but also offer North American buyers added assurance that their selected types of kitchen cabinet materials support both human health and long-term project durability.

Learn more: Cabinet certifications

4.3 Advanced Customization

Casta Cabinetry’s in-house design and engineering team leverages CAD/BIM workflows to support precision fabrication across a wide range of types of kitchen cabinet materials, from MDF and plywood to veneered blockboard and particle board.

- 3–5 Iterative Design Rounds: Rapid prototyping and virtual review sessions ensure every dimension, joint style, and grain pattern aligns with your specifications—no matter which types of kitchen cabinet materials are used for your base, wall, or tall units.

- Precision CNC Cutting: European-made CNC routers cut to ±0.1 mm tolerance, optimizing material yield and finish consistency across all types of kitchen cabinet materials, including high-density fiberboards and multi-ply plywood panels.

- Edge Banding & Finish Matching: Automated edge-banding stations apply seamless ABS or real-wood edges to every panel, while expert finish labs match paint, thermofoil, or veneer samples—regardless of the types of kitchen cabinet materials specified for the order.

This high level of customization ensures that every cabinet—whether RTA or pre-assembled—is built to exacting standards, with full compatibility across your chosen types of kitchen cabinet materials.

Learn more: Casta’s OEM cabinet manufacturer

4.4 Streamlined Logistics & Export Support

Understanding the complexities of international shipping, Casta Cabinetry offers logistics solutions specifically tailored for a wide range of types of kitchen cabinet materials, ensuring materials arrive safely, efficiently, and ready for installation:

- Flat-Pack & Knock-Down Packaging: Optimized crates and components are carefully configured for various types of kitchen cabinet materials, from lightweight MDF panels to multi-ply plywood carcasses—maximizing container space and reducing shipping costs.

- Pre-Assembled Container Loads: For projects that prioritize speed, fully assembled modular units made from different types of kitchen cabinet materials are delivered installation-ready, minimizing on-site labor and errors.

- U.S. Compliance Documentation: Casta Cabinetry prepares comprehensive export dossiers, including phytosanitary certificates, material safety data, and customs paperwork, for all shipments—regardless of the types of kitchen cabinet materials used. This ensures smooth clearance through ports and adherence to U.S. regulations.

By integrating manufacturing, certification, and end-to-end logistics, Casta Cabinetry simplifies the procurement of top-quality types of kitchen cabinet materials for buyers across the United States and Canada.

Learn more: Casta’s Outstanding International Projects

5. Certification & Safety Overview

Ensuring your project uses certified types of kitchen cabinet materials not only guarantees performance but also protects indoor air quality and sustainability goals. Below is a detailed look at the key certifications, the materials they cover, and why they matter for your next kitchen cabinet installation.

| Certification | Materials Covered | Purpose & Impact |

| CARB Phase 2 | MDF, Particle Board, Plywood | • Limits formaldehyde emissions to ≤0.05 ppm, safeguarding indoor air quality. |

| • Essential for kitchens in California and states adopting CARB rules. | ||

| FSC Mix-Credit | All wood-based substrates | • Verifies that wood fibers originate from responsibly managed forests. |

| • Supports green building certifications (LEED, WELL). | ||

| E1 (EU Standard) | MDF, Plywood, Particle Board | • Restricts total VOC emissions to ≤0.1 ppm, promoting healthier indoor environments. |

| • Recognized globally for low-emission engineered boards. | ||

| JIS Four-Star | MDF, Particle Board, Hardboard | • Japanese Industrial Standard marking highest quality and humidity resistance. |

| • Ideal for coastal or high-humidity regions where moisture damage is a concern. |

Why These Certifications Matter for Types of Kitchen Cabinet Materials

- Health & Compliance: Cabinets built from uncertified MDF or particle board can off-gas formaldehyde and VOCs, leading to occupant discomfort or regulatory fines.

- Environmental Responsibility: FSC Mix-Credit ensures your plywood or blockboard sourcing supports reforestation and ecosystem protection—critical for sustainable kitchen builds.

- Longevity & Performance: JIS Four-Star and E1 ratings correlate with superior moisture resistance and dimensional stability, reducing warping, delamination, and warranty claims over time.

Learn more: Non toxic kitchen cabinets

By selecting types of kitchen cabinet materials with these certificates, you’re delivering a healthier, more durable kitchen that aligns with both client expectations and industry standards.

6. New Trends & Technologies in Kitchen Cabinet Materials (2025)

The kitchen cabinetry market in 2025 is seeing a significant shift in both environmental responsibility and performance innovation. In addition to the traditional types of kitchen cabinet materials like plywood, MDF, and particle board, manufacturers are now incorporating high-tech and sustainable solutions to meet evolving customer demands—especially among contractors, cabinet brands, and developers seeking long-term value.

6.1. Sustainable & Bio-Based Composite Materials

Buyers are increasingly prioritizing eco-conscious options among the types of kitchen cabinet materials available in today’s market.

- Recycled Wood Fiber Panels: New-generation MDF substitutes now blend post-consumer wood fibers with low-emission adhesives, drastically reducing embodied carbon while maintaining strength and machinability.

- Bio-Based Resin Boards: Instead of urea-formaldehyde, some engineered boards now use resins derived from soy, lignin, or sugarcane—achieving lower VOCs and supporting green building standards like LEED.

Use Case: Ideal for environmentally certified projects or brands building a sustainable material story into their marketing.

6.2. Advanced Surface Technologies

A new wave of cabinet surfacing options adds functional benefits while extending the life of the material—especially when used on lower-cost core types of kitchen cabinet materials like MDF or particle board.

- Antibacterial Laminates: Surfaces infused with silver-ion or zinc-based compounds inhibit bacterial growth, making them ideal for residential kitchens, hospitals, or multifamily developments.

- Scratch-Resistant Coatings: High-pressure laminates and acrylic films are being enhanced with ceramic overlays or nano-layered technology, increasing scratch resistance by over 200% compared to traditional melamine.

Use Case: Perfect for rental units, hospitality projects, or high-traffic kitchens where cabinet materials face daily wear.

6.3. Lightweight Engineering for Modular Construction

Modern modular kitchens, mobile homes, and large-scale developments are turning to innovative core structures that reduce cabinet weight without compromising durability.

- Honeycomb-Core Sandwich Panels: These panels incorporate kraft paper or aluminum honeycomb cores between thin MDF or plywood skins—offering a high strength-to-weight ratio and excellent dimensional stability.

- CNC-Optimized Fiberboards: Upgraded types of MDF and HDF now offer enhanced edge density and uniformity—ensuring cleaner cuts and longer tool life during CNC routing, particularly in custom cabinet brands.

Use Case: Best suited for large cabinet programs with repeated CNC processing or lightweight transportation needs.

6.4. Smart & Functional Cabinet Material Innovations

Some newer types of kitchen cabinet materials include integrated features that improve usability and reduce maintenance across product lifecycles.

- Magnetic Surfaces: Laminated boards with integrated magnetic sheets enable homeowners to attach accessories or organizers directly to the cabinet surface—enhancing space efficiency without hardware.

- Thermo-Repair Finishes: Self-healing surface films respond to heat (steam or hot air), repairing micro-scratches and shallow dents over time. This extends the aesthetic longevity of doors and drawer fronts.

Use Case: Adds premium touch to mid-tier residential projects without increasing substrate costs.

By incorporating these emerging technologies into your material sourcing strategy, you expand your choices beyond the conventional types of kitchen cabinet materials. Whether you’re designing for high-end custom cabinetry or managing large-volume installations, adopting these innovations enhances both performance and brand differentiation.

7. Conclusion

By understanding the full range of types of kitchen cabinet materials—from plywood and MDF to particle board and hardboard—you can select substrates that balance strength, finish quality, and cost. Armed with performance comparisons, buyer-specific guidance, certification requirements, and insights into Casta Cabinetry’s capabilities, you’ll avoid common pitfalls and ensure durable, compliant installations. Apply these best practices to specify the ideal material for every kitchen project.

8. FAQ: Choosing Kitchen Cabinet Materials

Which material is best for moisture-prone areas?

What’s the best all-around material for cost and durability?

Are Vietnamese-sourced materials U.S. compliant?

What’s the most popular substrate for flat-pack (RTA) cabinets?

Can I get finish samples before bulk orders?

Are Flat Panel Cabinet Door Styles? Trends, Styles & Mar...

Cabinet door style does more than define a kitchen’s look—it shapes installation workflows, influences cost, and determi...

06/18/2025 | David Nguyen

What Is the Kitchen Cabinet Manufacturers Association (KCMA)...

Modular-home kitchens often derail schedules and budgets when off-the-shelf cabinets arrive the wrong size or demand on-...

06/14/2025 | David Nguyen

Why Vietnam Became a Top Supplier of Premium Furniture to Am...

Vietnam has rapidly become a go-to sourcing hub for wood furniture exports, especially for North American contractors, f...

06/07/2025 | David Nguyen

Top 10 Cabinet Door Manufacturers in 2025: Compare Quality, ...

In today’s competitive cabinetry market, contractors and cabinet/furniture brands need reliable partners for their door ...

06/04/2025 | David Nguyen

Contact us

Casta is always ready to listen and answer all customers' questions