Plywood kitchen cabinets are now one of the most preferred options in modern kitchen manufacturing, combining durability, cost-efficiency, and design flexibility in one material. For North American contractors, cabinet brands, and furniture manufacturers, plywood cabinets represent not only a practical material choice but also a long-term investment in quality, sustainability, and modern craftsmanship.

Table of Contents

1. Understanding Plywood Kitchen Cabinets: What They’re Made Of

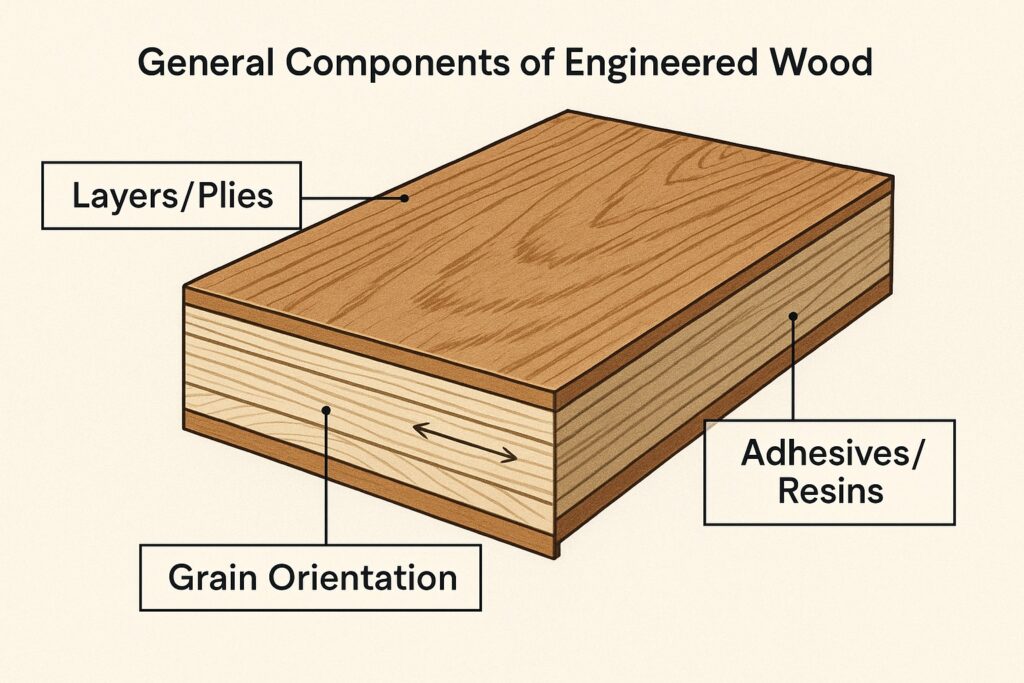

Plywood kitchen cabinets are engineered from multiple thin layers of wood veneer, each bonded under high heat and pressure using high-strength adhesives. This cross-laminated structure gives plywood its hallmark dimensional stability — resisting warping and bending even under fluctuating humidity.

Different grades of plywood serve specific cabinet applications:

- BWP (Boiling Water Proof): Ideal for areas with high moisture, such as under-sink bases or coastal kitchens.

- MR (Moisture Resistant): Suitable for general kitchen cabinetry and interior storage.

- CARB-certified plywood: Meets strict U.S. emissions standards, ensuring healthy indoor air quality.

When compared to MDF or particle board, plywood consistently outperforms in load-bearing capacity and structural rigidity, making it ideal for large-format kitchen designs and commercial-grade cabinetry.

Advanced manufacturing tools — particularly European CNC machines — enhance precision and ensure tight, consistent joints, maintaining seamless alignment throughout the kitchen layout.

2. The 5 Core Advantages of Plywood Kitchen Cabinets

Plywood kitchen cabinets have become a benchmark for premium and midrange cabinetry across the U.S. and Canada — primarily because they balance mechanical performance, design flexibility, and sustainability.

2.1 Superior Structural Strength

Plywood’s cross-grain construction gives it remarkable tensile strength, helping it withstand heavy countertop loads and resist sagging over time. For contractors handling large or open-plan kitchens, this stability translates into fewer call-backs and longer-lasting installations.

2.2 Moisture and Humidity Resistance

BWP and marine-grade plywood outperform MDF and particle board in humid conditions. This makes plywood especially valuable for kitchens in coastal states or basements where humidity is higher. Its dimensional stability helps maintain tight joints and door alignment over years of use.

2.3 Easy to Customize and Repair

For custom kitchen manufacturers and OEM brands, plywood is a dream substrate. It holds screws, hinges, and fasteners more securely, allowing for intricate joinery and hardware mounting. Plywood also takes veneers, laminates, and paints evenly — providing designers a wide palette of finish options from rustic oak to ultra-matte lacquer.

2.4 Lightweight Yet Durable

Despite its strength, plywood is surprisingly lightweight — reducing handling and shipping costs while maintaining rigidity. This advantage is critical in mass production and international shipping, where every kilogram counts.

2.5 Environmentally Responsible Option

Plywood kitchen cabinets are often produced using FSC-certified and E1-compliant materials, ensuring low formaldehyde emissions and sustainable wood sourcing. For brands prioritizing green manufacturing and compliance with LEED or CARB standards, plywood is a natural fit.

3. Limitations of Plywood Kitchen Cabinets — and How to Overcome Them

While plywood kitchen cabinets deliver strength and design versatility, they also come with specific challenges that can affect cost, aesthetics, and durability. Recognizing these early—and applying the right solutions—helps ensure consistency and performance in large-scale production or project use.

3.1 Cost Variation Based on Grade

The price of plywood varies widely depending on core type and veneer grade. High-grade plywood (like BWP or hardwood-faced) can be 20–40% more expensive than MDF, affecting project budgets.

Solution: Use mixed-grade planning — apply premium plywood for visible areas and cost-efficient core plywood for internal carcasses. This maintains both durability and design quality while keeping material costs under control.

3.2 Surface Imperfections Require Finishing

Being a natural material, plywood may show knots, uneven grain, or color variation that can affect surface uniformity.

Solution: Use veneer, laminate, or matte lacquer finishes for a clean, consistent surface. Automated sanding and controlled spraying systems help enhance smoothness while keeping the natural feel of wood.

3.3 Edge Exposure Issues

Plywood edges can absorb moisture or delaminate if left unsealed—especially in humid or high-use kitchen environments.

Solution: Apply CNC-machined precision edge banding with PUR adhesive for strong water resistance and seamless visual integration. Regular quality checks on sealing and corner bonding improve long-term stability.

3.4 Limited Availability in Certain Finishes

High-gloss or deep-matte coatings adhere better to MDF, limiting plywood’s ability to achieve some European-style glossy aesthetics.

Solution: Choose engineered finishes made for plywood substrates—such as PET films, lacquered veneers, or structured matte laminates—to achieve a premium, smooth appearance without compromising durability.

By applying these solutions, contractors and manufacturers can maximize the performance and visual appeal of plywood kitchen cabinets—delivering reliable quality that stands up to both design expectations and long-term use.

4. Plywood vs Other Kitchen Cabinet Materials

Choosing the right substrate material is a critical step in cabinet manufacturing and procurement. Each material—plywood, MDF, and particle board—has unique performance characteristics that affect durability, cost, weight, and visual outcomes. The comparison below helps contractors, designers, and sourcing teams identify the best fit for their project specifications.

| Material | Strength | Moisture Resistance | Weight | Cost | Durability | Ideal Use Case |

| Plywood | High | Excellent | Light | $$ | 15–20 years | Premium & midrange kitchens |

| MDF (Medium Density Fiberboard) | Medium | Moderate | Medium | $ | 10–15 years | Painted or lacquered cabinets |

| Particle Board | Low | Low | Light | $ | 5–10 years | Budget or temporary projects |

Detailed Analysis

- Plywood: Among all engineered woods, plywood offers the most balanced performance. It combines high structural strength, excellent screw-holding capacity, and resistance to warping — making it ideal for both residential and commercial kitchens. Modern multi-layer construction and phenolic bonding improve dimensional stability, while its light weight reduces shipping costs and eases installation.

- MDF: Known for its smooth surface and machinability, MDF is excellent for high-gloss or painted finishes. However, it is more susceptible to moisture swelling and lacks the rigidity of plywood. MDF suits indoor, low-humidity projects or where cost and visual uniformity take precedence over long-term durability.

- Particle Board: The most economical option, particle board is lightweight but less resistant to load and moisture, leading to faster wear in high-use kitchens. It works well for low-cost cabinetry or short-term builds, especially when laminated properly.

Comparative Insight

For manufacturers serving North American or export markets, plywood kitchen cabinets represent a strategic balance of durability, performance, and visual appeal. They outperform MDF in structural reliability and moisture tolerance while maintaining a lighter build than solid wood. When paired with CNC machining and automated edge sealing, plywood cabinetry achieves precision fit, reduced material waste, and consistent quality — meeting both aesthetic and operational expectations in modern kitchen production.

5. Design Possibilities with Plywood Kitchen Cabinets

Plywood isn’t just strong — it’s remarkably versatile. Its balanced structure and finish adaptability allow contractors and brands to deliver kitchen systems that are both elegant and durable. From modern minimalism to transitional shaker styles, plywood supports a wide range of design visions while maintaining precision and sustainability.

5.1 Modern Aesthetic Flexibility

Plywood kitchen cabinets offer exceptional design freedom. The natural wood texture brings warmth, while finishes like matte UV lacquers, laminates, or wood veneers create a refined look. It suits:

- European-style flat panels with clean, modern lines.

- Transitional shaker designs that mix tradition with modern function.

- Custom finishes and color palettes for distinctive brand aesthetics.

Its ability to accept diverse finishes evenly makes plywood a top choice for premium and midrange kitchen markets.

5.2 Structural Adaptability

Thanks to its cross-grain construction, plywood handles CNC machining, drilling, and routing with high precision. It easily supports:

- Handleless and modular systems for seamless, modern kitchens.

- Flat-pack production that simplifies shipping and installation.

- Consistent joinery and hardware fitting for repeat accuracy in manufacturing.

This versatility enhances production efficiency and ensures performance consistency across projects.

5.3 Sustainable and Safe Design

Certified under CARB Phase 2, E1, and FSC, plywood now meets strict sustainability and air-quality standards. Many panels feature low-VOC adhesives and eco-sourced veneers, making them ideal for LEED-certified or green projects.

For contractors and brands, plywood’s eco-friendly profile and durability reinforce its value as a smart, long-term material choice.

Learn more: Kitchen cabinet trends

6. How to Choose Quality Plywood Kitchen Cabinets: A 5-Step Guide

Selecting the right plywood kitchen cabinet supplier is just as important as choosing your cabinet design. A great design means little if the material fails in durability or precision.

Below is a five-step checklist to help contractors, importers, and furniture brands make informed sourcing decisions and ensure consistent quality across every batch.

6.1 Check Certifications

- Always verify CARB Phase 2, E1, or FSC certifications. These confirm that the plywood meets North American formaldehyde emission and sustainability standards.

- Certified materials not only protect end users’ health but also help brands qualify for LEED or green building credits.

6.2 Understand Material Composition

- Request documentation specifying core type (hardwood or softwood), veneer thickness, and adhesive type.

- High-quality plywood typically features uniform veneers and cross-laminated layers bonded with low-VOC phenolic or melamine adhesives for stability and moisture resistance.

6.3 Inspect Machining Precision

- Examine edge banding, joint alignment, and cutting consistency.

- A reliable manufacturer will use CNC machines and automated edge banders, ensuring perfect fitment and minimal deviation across panels.

- This precision directly influences how well doors align, close, and perform over years of use.

6.4 Compare Strength-to-Weight Ratio

- Choose plywood that aligns with your project’s load requirements — heavier panels may offer higher strength but could increase transport and installation costs.

- For large-scale modular kitchens, 12–18 mm panels often strike the ideal balance between rigidity and handling efficiency.

6.5 Partner with a Reliable OEM Manufacturer

- Work with experienced OEM or ODM manufacturers that offer customizable designs, flexible MOQ, and technical support.

- Consistent supply, transparent QC reports, and responsive after-sales service are indicators of a dependable long-term partner.

Learn more: Top rated cabinet manufacturers

7. Case Study: Delivering Plywood Kitchen Cabinets with European Precision — Casta Cabinet

Casta Cabinet, a Vietnam-based OEM supplier for North American brands, demonstrates how advanced technology and global craftsmanship can elevate plywood kitchen cabinet production. The company merges European engineering standards with Vietnamese manufacturing efficiency, achieving exceptional quality at competitive cost.

7.1 Technology & Precision

- Equipped with Homag and Biesse CNC machinery, Casta ensures ±0.1 mm machining accuracy across all components.

- Automated edge-banding guarantees tight seams, moisture resistance, and smooth surface finishes.

- Every cabinet passes through a multi-stage QC process—measuring bonding strength, panel thickness, and finish consistency.

7.2 Certifications & Quality Standards

- CARB Phase 2, E1, and FSC Mix Credit certified plywood for low formaldehyde emissions and sustainable sourcing.

- Internal lab testing monitors moisture content and adhesive integrity to meet North American durability expectations.

- 95% defect-free delivery rate, verified through systematic inspection and performance tracking.

7.3 Logistics & Production Efficiency

- Lead Time: 30–45 days (port-to-door) for U.S. and Canada.

- MOQ: 20 kitchen sets — suitable for small brands or large-scale distributors.

- Production Capacity: Over 1,000 kitchen sets per month.

7.4 Value for Contractors & Brands

By combining Vietnam’s operational efficiency with European-level precision, Casta enables North American cabinet brands to deliver:

- Consistent product quality and finish uniformity.

- Lower overhead costs compared to domestic production.

- Scalable sourcing for premium plywood kitchen cabinets.

Learn more: Casta’s outstanding international projects

8. Conclusion: The Balanced Choice for Modern Kitchens

Plywood kitchen cabinets stand out as the perfect middle ground between strength, aesthetics, and sustainability. They outperform MDF and particle board in most functional areas while offering flexibility for designers and manufacturers alike.

For contractors and cabinet brands across North America, partnering with certified plywood suppliers — particularly those using European technology and precision-driven production — ensures every project delivers long-term value, stability, and timeless appeal.

9. Frequently Asked Questions (FAQ)

Are plywood kitchen cabinets more durable than MDF?

What grade of plywood is best for kitchen use?

Are plywood cabinets water-resistant?

How long do plywood kitchen cabinets last?

Do plywood cabinets cost more to import or manufacture?

Top Cabinet Manufacturers in Florida: A Capability-Based Buy...

Cabinet manufacturers in Florida play a critical role in one of the fastest-growing construction markets in North Americ...

01/10/2026 | David Nguyen

Top North Carolina Cabinet Manufacturers | Best NC Kitchen ...

North Carolina cabinet manufacturers have long been trusted across the U.S. thanks to the state’s deep heritage in woodw...

01/08/2026 | David Nguyen

Top Cabinet Manufacturers in Arizona | Best Arizona Kitchen ...

Cabinet manufacturers in Arizona have gained increasing attention as construction activity accelerates across Phoenix, T...

01/06/2026 | David Nguyen

Top Cabinet Manufacturers Indiana | Best Indiana Kitchen Cab...

Cabinet manufacturers Indiana have become increasingly relevant as contractors and developers look for dependable Midwes...

01/04/2026 | David Nguyen

Contact us

Casta is always ready to listen and answer all customers' questions