Selecting the right material for cabinets or furniture is crucial for contractors, furniture brands, and companies.

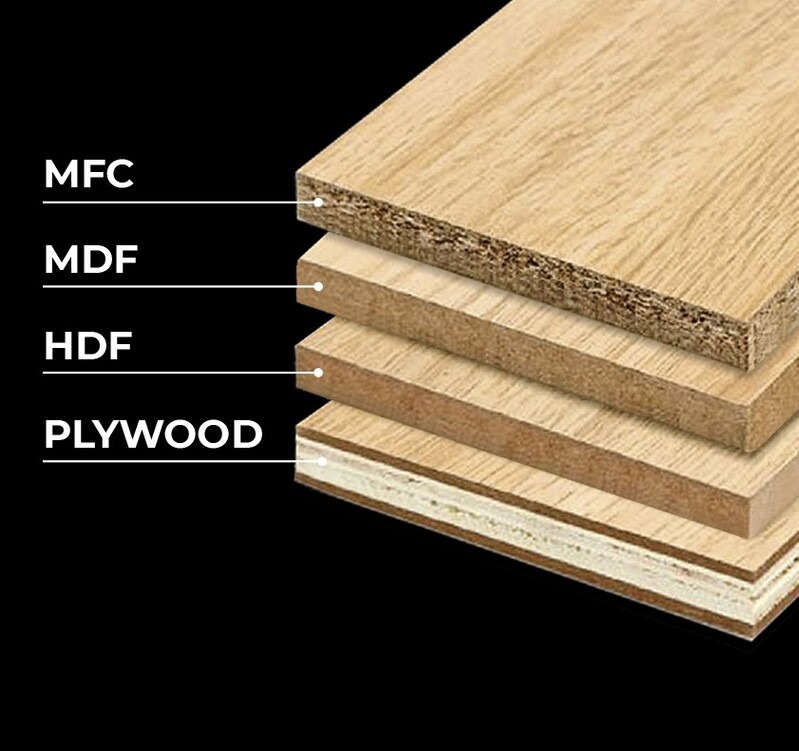

With so many options on the market—MDF (Medium-Density Fiberboard), MFC (Melamine-Faced Chipboard), Plywood, and HDF (High-Density Fiberboard)—each material brings unique qualities, costs, and benefits.

Understanding the difference between MDF and MFC vs Plywood vs HDF can help you make the best decision for your specific project needs, whether it's for kitchen cabinetry, custom office furniture, or a large-scale commercial development.

Table of Contents

Introduction to HDF, Plywood, MDF and MFC

When it comes to materials for cabinetry and furniture, MDF, MFC, Plywood, and HDF are among the most popular choices, each known for its unique properties. Depending on the requirements—such as durability, resistance to moisture, cost-effectiveness, and aesthetic appeal—one material may be better suited to a project than another. For instance, high-end kitchen cabinets may benefit from Plywood or HDF due to their durability, while budget projects may lean towards MDF or MFC.

Let’s explore the differences between these materials, helping contractors and furniture brands make the best decisions for their clients, all while staying within budget and ensuring long-lasting quality.

Learn more: Types of Kitchen Cabinet Materials

What Is MDF (Medium-Density Fiberboard)?

MDF, or Medium-Density Fiberboard, is one of the most versatile and cost-effective materials used in the furniture and cabinetry industries. MDF is manufactured by breaking down softwood or hardwood residuals into wood fibers, combining it with wax and resin, and forming panels under high temperature and pressure. The result is a smooth and dense material that is easy to cut, drill, and shape, making it a favorite among furniture makers who need precision in their designs.

Advantages of MDF:

- Affordability: MDF is significantly cheaper than Plywood or HDF, making it a popular choice for budget-conscious projects.

- Smooth Surface: Its uniform surface is ideal for painting and veneering, allowing for a variety of finishes.

- Ease of Customization: MDF can be easily cut and shaped, making it great for detailed and intricate furniture designs.

Despite these benefits, MDF has its limitations. One of the main concerns with MDF is its lack of moisture resistance. When exposed to water, MDF can swell and lose its structural integrity. As a result, it is not suitable for areas like kitchens and bathrooms unless treated with specialized finishes. Additionally, MDF can be heavier than other materials like Plywood, making it more challenging to install in some applications.

Key Uses for MDF:

- Interior cabinetry (away from moisture)

- Decorative panels

- Painted furniture pieces

- Shelving units

What Is MFC (Melamine-Faced Chipboard)?

MFC, or Melamine-Faced Chipboard, is a particleboard core laminated with a melamine coating. This material is popular for kitchen cabinets and office furniture due to its moisture resistance and durable surface. MFC is more resistant to everyday wear and tear than MDF because of its tough outer layer of melamine, which can also come in various finishes, colors, and textures, allowing for more design flexibility.

One of the significant advantages of MFC over MDF is its ability to withstand moisture, making it a better choice for kitchens and bathrooms. However, while MFC is more durable than MDF, its core is still chipboard, which means it doesn’t offer the same structural strength as Plywood or HDF.

Advantages of MFC:

- Moisture Resistance: The melamine coating provides an added layer of protection against water damage, making MFC a suitable choice for kitchen and bathroom applications.

- Durable Surface: The outer layer is scratch-resistant and easy to clean, making it ideal for high-traffic areas.

- Wide Range of Colors and Finishes: MFC can mimic wood grains, metallics, and solid colors, allowing it to fit in with various design aesthetics.

Despite these advantages, MFC is susceptible to damage during cutting and installation, as the melamine layer can chip if not handled with care. Additionally, while MFC is moisture-resistant, it is not completely waterproof, so it still requires careful placement in wet areas.

Key Uses for MFC:

- Kitchen and bathroom cabinets

- Office furniture

- Wardrobes

- Shelving systems

What Is Plywood?

Plywood is one of the oldest and most trusted materials in furniture and cabinetry manufacturing. Made by layering thin sheets of wood veneer and bonding them together with adhesive, Plywood is known for its strength, stability, and resistance to warping. Each layer is oriented at a 90-degree angle to the one below it, which gives Plywood its impressive strength and makes it highly resistant to expansion and contraction caused by moisture.

Advantages of Plywood:

- Durability and Strength: Plywood is much stronger than MDF and MFC, making it suitable for heavy-duty applications and load-bearing furniture.

- Moisture Resistance: Plywood can handle exposure to moisture better than MDF or MFC, making it ideal for kitchens, bathrooms, and outdoor furniture.

- Versatility: Available in various grades and thicknesses, Plywood can be used for everything from cabinet frames to decorative paneling.

One of the main drawbacks of Plywood is its cost, which is generally higher than MDF and MFC. However, for clients looking for long-lasting, moisture-resistant cabinetry, the investment in Plywood often pays off in terms of durability and performance. Another consideration with Plywood is its exposed edges, which often need finishing or veneering to achieve a polished look.

Key Uses for Plywood:

- Cabinet frames

- Kitchen and bathroom cabinetry

- Subflooring

- Outdoor furniture

What Is HDF (High-Density Fiberboard)?

HDF, or High-Density Fiberboard, is an upgrade from MDF, offering greater density, strength, and durability. Like MDF, HDF is made by compressing wood fibers under extreme pressure, but the result is a much harder and denser board. HDF is often used in premium cabinetry, flooring, and commercial furniture that requires longevity and high resistance to wear and tear.

Advantages of HDF:

- High Durability: HDF is much stronger than both MDF and MFC, making it ideal for high-traffic areas and heavy-duty applications.

- Smooth Finish: The denser surface allows for flawless finishes, making HDF a popular choice for high-end cabinetry.

- Moisture Resistance: While not as moisture-resistant as Plywood, HDF can handle moderate exposure to water, especially when sealed properly.

However, HDF is more difficult to work with than MDF or Plywood due to its density, requiring special tools and equipment. This also makes it more expensive, but its longevity and premium look make it a worthy investment for high-end projects.

Key Uses for HDF:

- Premium kitchen cabinetry

- Flooring

- Commercial furniture

Key Differences Between MDF and MFC vs Plywood vs HDF

Here’s a detailed comparison of MDF, MFC, Plywood, and HDF based on the most important factors for cabinetry and furniture-making:

| Feature | MDF | MFC | Plywood | HDF |

| Durability | Moderate | High | Very High | Extremely High |

| Moisture Resistance | Low (unless sealed) | High | Very High | Moderate |

| Workability | Easy to cut | Requires precision | Easy to cut | Difficult to cut |

| Cost | $100 - $200 per linear ft | $150 - $250 per linear ft | $200 - $350 per linear ft | $300 - $400 per linear ft |

| Best For | Budget-conscious projects | Kitchens and bathrooms | High-end and structural applications | Premium, heavy-duty cabinetry |

Best Customers for Each Material

Different materials are better suited for different types of customers and projects. Here's a guide to help contractors, furniture brands, and companies understand which material is the best fit for various projects:

- MDF: Perfect for budget-conscious customers looking for affordable solutions. Ideal for interior cabinetry and furniture in dry spaces.

- MFC: Best for kitchens, bathrooms, and other areas prone to moisture. Its pre-finished surface makes it ideal for quick installations in residential or commercial settings.

- Plywood: Suitable for high-end residential projects, as well as commercial applications where durability and strength are crucial. Best for cabinetry that needs to withstand moisture.

- HDF: Ideal for high-traffic areas and clients seeking premium-quality materials. Used in commercial settings or luxury homes where longevity is important.

Casta’s Commitment to High-Quality Cabinet Materials

At Casta Cabinetry - one of the top rated cabinet manufacturers in Vietnam, we focus on top-quality materials, precision manufacturing, custom design, and excellent support to deliver high-performance cabinets.

European Machinery and Manufacturing

Casta uses state-of-the-art European machinery to ensure precision in every product. This allows for perfectly crafted MDF, MFC, Plywood, and HDF cabinets, giving each project a sophisticated and durable finish.

Custom Design and Customer Satisfaction

Casta specializes in custom cabinets, tailoring every aspect of the cabinets to the client's preferences. We ensure customer satisfaction through personalized consultations, making the process seamless and collaborative.

Health Certifications

Our materials are compliant with CARB and E1/E0 European Formaldehyde Standards, providing cabinets that are eco-friendly and safe for indoor use. We prioritize non-toxic solutions to enhance indoor air quality.

Support on Delivery

From design to delivery, Casta ensures smooth and timely cabinet installations. Our comprehensive support guarantees that cabinets arrive in perfect condition and are installed to meet client expectations.

Sustainability and Environmental Considerations

With a growing emphasis on sustainability, choosing eco-friendly materials has become crucial for contractors and companies. Here's how each material compares:

- MDF: Available in low-formaldehyde options, making it more sustainable. However, it’s less eco-friendly due to the adhesives used.

- MFC: While melamine is non-toxic, its chipboard core is less sustainable unless it comes with certifications like FSC.

- Plywood: Often sourced from sustainable wood, Plywood is the most eco-friendly option if you choose FSC-certified wood veneers.

- HDF: Like MDF, HDF can be more eco-friendly if it is manufactured using low-emission adhesives.

Conclusion

In conclusion, understanding the difference between MDF and MFC vs Plywood vs HDF is essential for making informed decisions in cabinetry and furniture projects. MDF offers affordability, MFC provides durability with moisture resistance, Plywood ensures long-lasting structural integrity, and HDF is perfect for high-end, heavy-duty applications. By selecting the right material, contractors and furniture brands can meet the needs of their customers, providing both aesthetic appeal and functional durability.

Whether your project demands high-end, moisture-resistant cabinetry for a luxury kitchen or budget-friendly furniture for a commercial space, there’s a material to fit your needs.

FAQ

What is the difference between MDF and MFC?

Is Plywood better than MDF?

Can I use HDF for kitchen cabinets?

Is MFC suitable for bathrooms?

Which material is the most eco-friendly?

Top Cabinet Manufacturers in Florida: A Capability-Based Buy...

Cabinet manufacturers in Florida play a critical role in one of the fastest-growing construction markets in North Americ...

01/10/2026 | David Nguyen

Top North Carolina Cabinet Manufacturers | Best NC Kitchen ...

North Carolina cabinet manufacturers have long been trusted across the U.S. thanks to the state’s deep heritage in woodw...

01/08/2026 | David Nguyen

Top Cabinet Manufacturers in Arizona | Best Arizona Kitchen ...

Cabinet manufacturers in Arizona have gained increasing attention as construction activity accelerates across Phoenix, T...

01/06/2026 | David Nguyen

Top Cabinet Manufacturers Indiana | Best Indiana Kitchen Cab...

Cabinet manufacturers Indiana have become increasingly relevant as contractors and developers look for dependable Midwes...

01/04/2026 | David Nguyen

Contact us

Casta is always ready to listen and answer all customers' questions