In the world of cabinetry, craftsmanship goes beyond the surface. The strength, durability, and aesthetic appeal of a cabinet lie largely in its joints. Cabinet joints are more than just connections; they are the foundation that determines whether a cabinet can withstand the test of time, heavy usage, and environmental changes. For contractors and cabinet brands alike, understanding the types of joints for cabinets is essential for delivering high-quality, durable, and aesthetically pleasing products.

For North American contractors and cabinet brands, selecting the right cabinet joints plays a crucial role in the longevity and stability of the final product. Whether it’s a luxury kitchen installation or a large-scale commercial project, choosing the right joint type ensures that the cabinets meet both functional and design requirements. This guide will explore the best joints for cabinets, focusing on wood joints for cabinets and key cabinet door joint types. You’ll learn how different joints function, their ideal applications, and how they impact the overall durability and aesthetics of cabinets.

Table of content

1. Why Quality Joints Matter in Cabinet Construction

The quality of joints in cabinet construction goes beyond the initial appearance of a cabinet. High-quality joints determine the structural integrity of the unit, ensuring that it can endure daily wear and tear, weight, and stress over time. Poor-quality joints may fail under pressure, causing doors to misalign, shelves to sag, or entire cabinets to weaken over time. This is especially critical in environments such as kitchens and bathrooms, where cabinets are exposed to moisture, heat, and frequent use.

For contractors and cabinet brands, this means that the right joints can make the difference between a successful project and costly repairs down the road. Investing in strong, well-crafted joints ensures that cabinets remain sturdy and reliable for years, offering long-term value to clients and reducing the need for replacements. According to industry data, cabinets with high-quality joints can extend their lifespan by up to 30%, making them a smart investment for both homeowners and commercial projects.

At Casta Cabinetry, we use European machinery to ensure that every joint is precisely crafted. Our focus on precision ensures that each cabinet is not only visually appealing but also structurally sound, capable of withstanding the rigors of daily use. The result is a product that delivers both durability and aesthetic appeal, ensuring that contractors and brands can meet the expectations of their clients with confidence.

Learn more: Material & Finish Innovations: How Modern Cabinet Manufacturers Elevate Design and Durability

2. Top 5 Most Common Types of Joints for Cabinets

Understanding the different types of joints used in cabinetry is essential for ensuring the strength, durability, and appearance of your final product. Below, we delve into the top 5 most common joints used in cabinet construction, explaining how they work, their strengths, and their ideal applications.

2.1 Dado Joint

The dado joint is widely used in cabinet construction for its ability to create strong, stable connections between cabinet sides and shelves. A dado is a groove cut into one piece of wood that allows another piece to sit firmly inside. This joint is commonly used in kitchen and bathroom cabinets where heavy items like cookware, dishes, or toiletries need to be supported by shelving.

- Applications: Connecting shelves to the sides of the cabinet.

- Strengths: Excellent stability, especially for shelving that must bear significant weight.

- Weaknesses: Requires precise cuts and professional equipment for clean execution.

- Example: Dado joints are ideal for kitchen cabinets where shelves need to support heavy loads like pots, pans, and pantry items.

2.2 Dovetail Joint

The dovetail joint is one of the strongest and most aesthetically appealing joints used in cabinetry. It involves interlocking “tails” and “pins” that fit together to form a secure, durable connection. Dovetail joints are commonly used in high-end cabinetry, particularly for drawers, where they are subjected to frequent opening and closing.

- Applications: Drawers and cabinet corners.

- Strengths: Extremely strong and visually appealing, making it a preferred choice for luxury and traditional cabinetry.

- Weaknesses: Time-consuming to create, especially without precise machinery.

- Example: Dovetail joints are commonly used in custom kitchen drawers where both strength and appearance are essential.

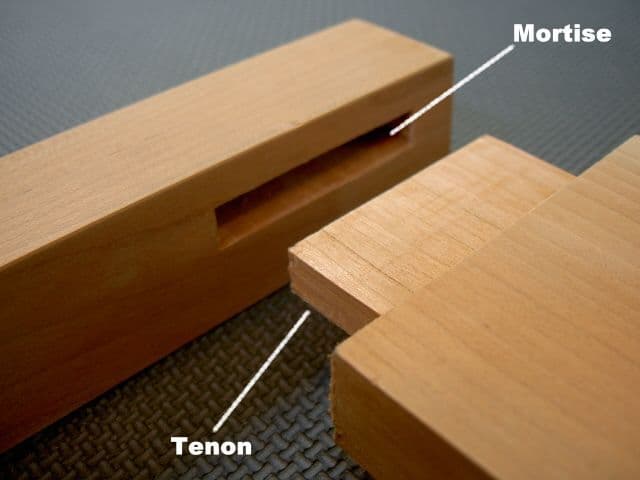

2.3 Mortise and Tenon Joint

The mortise and tenon joint is one of the oldest and most reliable joints in woodworking, known for its strength and durability. The "tenon" is inserted into the "mortise" (a hole or cavity) to create a tight, secure bond. This joint is commonly used in cabinet frames and doors, where strength is essential for long-lasting performance.

- Applications: Cabinet frames and doors.

- Strengths: Highly durable and able to withstand significant stress.

- Weaknesses: Requires skill and precision to execute correctly.

- Example: Mortise and tenon joints are often found in high-quality cabinet doors that need to maintain alignment and structural integrity over time.

2.4 Butt Joint

The butt joint is the simplest of all joints, where two pieces of wood are simply butted together and fastened with screws, nails, or adhesives. While easy and quick to assemble, butt joints lack the strength of more complex joints and are typically used in budget-conscious cabinetry.

- Applications: Basic cabinetry, low-end or modular cabinets.

- Strengths: Quick and easy to assemble, making it cost-effective for simple projects.

- Weaknesses: Lacks the strength and durability of more complex joints.

- Example: Butt joints are often used in lower-end modular cabinetry where cost is a primary concern.

2.5 Rabbet Joint

The rabbet joint is another commonly used joint in cabinet construction. It involves cutting a recess along the edge of one piece of wood to allow another piece to fit into it. This joint is often used to attach the back panels of cabinets or drawer bottoms, providing a clean, seamless finish.

- Applications: Cabinet backs and drawer bottoms.

- Strengths: Provides a clean and seamless finish for vertical surfaces like the back of cabinets.

- Weaknesses: Not as strong as dovetail or mortise and tenon joints.

- Example: Rabbet joints are used in the back panels of kitchen cabinets to provide a smooth, professional finish.

3. Best Joints for Specific Cabinet Parts

When constructing cabinets, it’s important to select the right joint for each component to ensure long-term durability and stability. Here’s a breakdown of the best joints for different parts of a cabinet:

3.1 Frames and Structure

- Best Joint: Dado Joint.

- Analysis: Dado joints are capable of supporting up to 25% more weight than butt joints, making them ideal for shelves and other structural components that bear heavy loads. This strength makes them a preferred choice for kitchen cabinets that store heavy pots, pans, and cookware.

3.2 Drawers

- Best Joint: Dovetail Joint.

- Analysis: Dovetail joints offer 30% more durability than rabbet joints in drawer construction. Their interlocking design resists the pulling forces exerted on drawers during daily use, making them the best choice for high-quality, frequently used drawers.

3.3 Cabinet Doors

- Best Joint: Mortise and Tenon.

- Analysis: Mortise and tenon joints are designed to withstand tension and torque, making them ideal for cabinet doors. This joint ensures that doors maintain their alignment over time, even with repeated use, providing superior durability.

4. How to Choose the Right Joint for Your Project

Selecting the right joint for your cabinet project depends on several factors, including cost, timeline, and the specific needs of your client. Here’s what to consider:

4.1 Cost Analysis

- Dovetail and Mortise and Tenon Joints: These joints are more labor-intensive, often adding 15-25% to production costs. However, they provide superior strength and longevity, making them ideal for high-end cabinetry where long-term durability is essential.

- Butt Joints and Pocket Hole Joints: These joints are quicker and easier to assemble, reducing labor costs. However, they may require additional reinforcement, which can increase long-term maintenance costs.

4.2 Timeline Considerations

- Dovetail and Mortise and Tenon Joints: These joints take more time to construct but offer long-lasting durability. Contractors should allow extra time for these more complex joints to ensure precision and strength.

- Butt Joints and Rabbet Joints: These joints are faster to assemble, reducing production time by up to 10%, making them ideal for projects with tight deadlines. However, they may not offer the same long-term durability as more complex joints.

4.3 Aesthetic Impact

- Dovetail and Mortise and Tenon Joints: These joints provide both strength and visual appeal, making them ideal for exposed cabinetry where aesthetics are important.

- Butt and Pocket Hole Joints: These joints are less visually appealing but can be used in areas where the joints will be hidden or where cost is a primary consideration.

5. Common Mistakes to Avoid When Choosing Joints for Cabinets

When choosing joints for cabinet construction, it’s important to avoid common mistakes that can compromise the durability and appearance of the final product. Here are some mistakes to avoid:

5.1 Using Weak Joints in High-Traffic Areas

Using weak joints like butt joints in high-traffic or load-bearing areas can lead to premature failure. Instead, opt for stronger joints like dovetail or mortise and tenon for these areas.

5.2 Choosing Cost Over Quality

While it may be tempting to choose cheaper joints to reduce costs, this can lead to higher maintenance and replacement costs in the long run. Investing in high-quality joints from the outset ensures long-term durability.

5.3 Neglecting Aesthetic Considerations

Choosing the wrong joint can affect the overall aesthetic of the cabinet. For example, using butt joints in high-end cabinetry can detract from the visual appeal. Instead, opt for joints that complement the design and style of the cabinetry.

Learn more: Industrial Cabinet Manufacturers: The Best Choice for Quality & Cost-Effective Solutions

6. Casta Cabinetry: Ensuring Precision in Every Joint

At Casta Cabinetry, we understand the importance of precision in every joint. Using European machinery, we ensure that each joint is crafted to perfection, providing the strength and durability needed for long-lasting cabinetry. Whether it’s dovetail joints for drawers or mortise and tenon joints for doors, our attention to detail ensures that every cabinet we produce meets the highest standards of quality.

Our commitment to quality extends beyond aesthetics and into functionality. We carefully select materials that are CARB and FSC certified, ensuring that our cabinets are both environmentally friendly and safe for use in any home or commercial space. By choosing Casta Cabinetry, contractors and brands can expect nothing less than excellence in every joint.

Learn more: ISO-Qualified Cabinet Certification

Choosing the right joints for cabinets is essential for ensuring durability, strength, and aesthetic appeal. By selecting high-quality joints such as dovetail or mortise and tenon, contractors and brands can ensure that their cabinets will not only last longer but also perform better over time. Investing in premium joints offers long-term value by reducing the need for repairs or replacements.

Learn more: Top Kitchen Cabinets Manufacturer

Whether you’re building custom kitchen cabinets or designing for a large commercial project, prioritizing the right joints can make all the difference. Casta Cabinetry is here to provide expert guidance and precision craftsmanship, ensuring that every cabinet we produce exceeds your expectations.

FAQ

What is the strongest joint for cabinet drawers?

Can butt joints be used for cabinet shelving?

How do different joint types impact project costs?

Learn more: Top Ready to Assemble Furniture Manufacturers

How Much Do Soft Close Cabinets Cost? 2025 Pricing Analysis ...

Soft close cabinets—equipped with hydraulic or pneumatic damping mechanisms—have become the industry standard for kitche...

06/28/2025 | David Nguyen

Soft Close vs Self Close Cabinet Hinges: Differences, Pros &...

Cabinet hinges play a pivotal role in the daily functionality and perceived quality of kitchen and furniture installatio...

06/26/2025 | David Nguyen

20 Glass Front Cabinet Ideas for Contractors & Kitchen C...

Glass front cabinet doors have surged in popularity across modern kitchen and cabinetry programs, offering contractors a...

06/24/2025 | David Nguyen

Are Hardboard Cabinets Good? Pros, Uses & Comparisons Ex...

Choosing the right kitchen cabinet materials can make or break a project’s success. Material selection influences durabi...

06/20/2025 | David Nguyen

Contact us

Casta is always ready to listen and answer all customers' questions