In today’s competitive market, American standard cabinets are more than just storage solutions—they set the benchmark for quality, durability, and safety. Contractors, cabinet brands, and companies in North America rely on American standard cabinets, built to strict ASTM and ANSI standards, for consistent performance and ease of installation. Whether you’re specifying American standard kitchen cabinets or outfitting commercial spaces, these cabinets deliver the reliability and precision that modern projects demand.

This guide explores what defines American standard cabinets, their key features, benefits, and how manufacturers use advanced production and sustainable practices to exceed expectations.

Learn how adopting American standard kitchen cabinets can enhance functionality, aesthetics, and overall project value.

Table of Contents

1. Understanding American Standard Cabinets

1.1 What Defines American Standard Cabinets?

a. Definition:

American standard cabinets are cabinetry products that are engineered to meet strict industry benchmarks established by organizations such as ASTM and ANSI. These cabinets are designed with precise dimensions, consistent construction, and robust material quality to ensure uniformity, durability, and safety in every installation. In essence, American standard cabinets provide a predictable performance and ease of installation that is critical for both residential and commercial projects.

b. Key Characteristics of American Standard Cabinets:

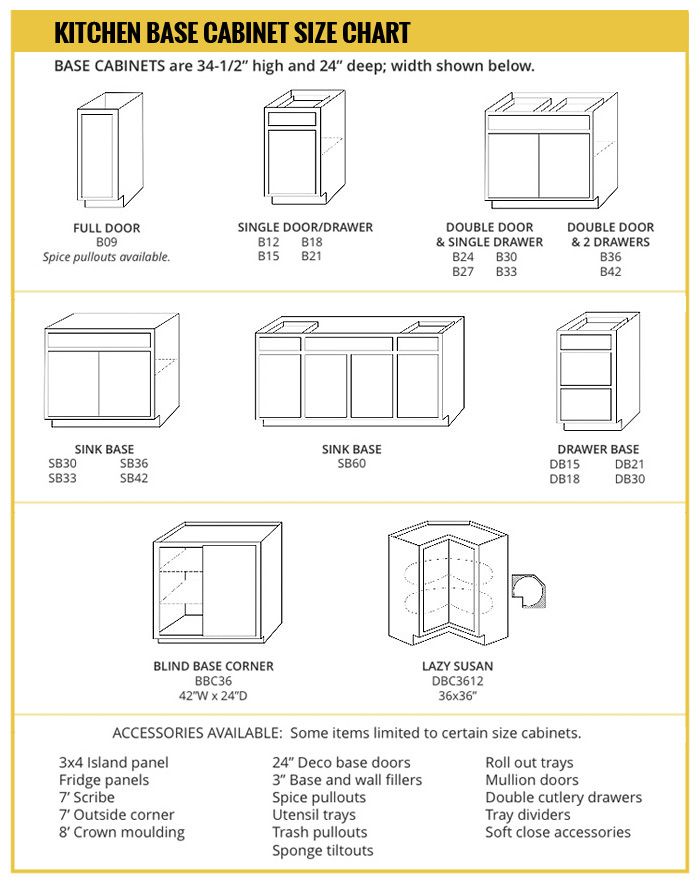

- Precise Dimensions & Design:

- Adherence to industry standards guarantees uniform door heights, consistent shelf depths, and proper hardware alignment. This precision makes installation straightforward and minimizes errors in large-scale projects.

- Superior Material Quality:

- Constructed using premium, certified woods and high-grade engineered panels, American standard kitchen cabinets are renowned for their ability to withstand heavy usage while maintaining an elegant appearance.

- Robust Construction & Customization:

- These cabinets are built to endure intense daily use without compromising on style. They also offer customization options that allow for tailored solutions to meet specific functional and aesthetic requirements.

- Health & Safety Compliance:

- The use of low VOC finishes and certified materials ensures that American standard cabinets provide a healthier indoor environment, which is especially important in both commercial and residential settings.

1.2 The Importance of These Standards

From a buyer’s perspective, the strict standards behind American Standard Cabinets are essential for several key reasons:

- Enhanced Functionality:

- Optimized Storage: Uniform dimensions and precise design of American Standard Cabinets ensure maximum storage efficiency and reliable performance even in high-traffic environments.

- Long-Term Durability: Engineered for everyday use, these cabinets offer robust construction that guarantees longevity, making them an excellent investment for both residential and commercial projects.

Learn more: Industrial Cabinets Made in Vietnam: Durability and Functionality for Demanding Applications

- Safety & Health Assurance:

- Low-Emission Materials: The incorporation of certified, low-VOC finishes in American Standard Cabinets significantly reduces harmful pollutants, thereby improving indoor air quality.

- Health Benefits: This commitment to using eco-friendly and non-toxic materials is especially important in spaces where occupant safety is paramount.

Learn more: Non toxic kitchen cabinets

- Consistency & Ease of Installation:

- Uniform Standards: Adherence to strict industry benchmarks (e.g., ASTM/ANSI) ensures that every American Standard Cabinet is consistent in quality. This uniformity simplifies installation, maintenance, and future replacements.

- Compatibility: The standardization guarantees seamless integration in multi-unit developments and large-scale projects.

- Value & Buyer Confidence:

- Proven Quality: Knowing that your cabinets meet rigorous standards instills confidence in their performance and longevity, which is why American Standard Cabinets are highly preferred by contractors and developers.

- Cost-Effectiveness: Consistent quality reduces the risk of errors and unexpected maintenance costs, delivering long-term value to every project.

2. Key Standard Features & Proven Benefits

Standard cabinetry built to American standards stands apart by delivering unmatched precision, durability, and versatility. Below are the core features that define these premium kitchen cabinets, along with the proven benefits they bring to modern projects.

2.1 Superior Material Quality

- Premium Components:

Leading manufacturers use certified solid wood (FSC/PEFC) and eco-friendly engineered panels, ensuring a lifespan of over 20 years. These high-quality materials provide exceptional strength and an attractive finish, making them ideal for high-end kitchen installations.

- Sustainability & Durability

Utilizing renewable, eco-friendly materials minimizes environmental impact while ensuring long-term performance and reduced maintenance costs.

Learn more: Material & Finish Innovations: Elevating Cabinet Design and Durability

2.2 Precision Manufacturing

- Advanced Production:

State-of-the-art European machinery in Vietnam enables production with cutting tolerances as fine as 0.1% and waste reduction below 2%. This technology ensures that every unit is crafted to exact standards.

- Efficiency & Consistency:

Automated production processes yield uniform, reliable products that simplify installation and guarantee consistent quality across all projects.

2.3 Full Customization Process

- Iterative Design Rounds:

An in-depth design process involving 3–5 rounds of refinement allows for extensive customization, ensuring each cabinet is tailored to the unique requirements of every project.

- Design Flexibility & Efficiency:

Custom options—ranging from bespoke finishes to precise dimensions—reduce the need for rework and streamline installation, saving time and cost while meeting specific project needs.

Learn more: Understanding the Cost of Custom Cabinetry: A Comprehensive Guide

2.4 Certified Health & Safety Standards

- Low Emission & Eco-Friendly Sourcing:

Production relies on materials with low VOC emissions, ensuring products are safe for indoor environments. Certification from bodies like CARB and FSC validates these standards.

- Consumer Confidence:

Rigorous adherence to health and safety benchmarks provides peace of mind, making these kitchen cabinets an excellent choice for projects where indoor air quality is a priority.

2.5 Reliable Delivery & Customer Support

- Robust Logistics:

An efficient supply chain achieves on-time delivery rates of over 98%, crucial for projects with tight deadlines.

Learn more: Lead Times & Supply Chain Resilience: Navigating Potential Disruptions

- Dedicated Support:

Responsive customer service and after-sales support ensure that any issues are promptly addressed, reinforcing trust and reliability in the product.

2.6 Exceptional Aesthetic & Functional Design

- Adherence to Standards:

Designed to meet American industry guidelines, these cabinets offer optimal functionality, streamlined installation, and a modern, elegant look.

- Versatile Styles:

Available in a variety of designs—from minimalist modern to intricate traditional—these cabinets suit any interior décor and project requirement.

- Client-Verified Excellence:

Positive testimonials and case studies confirm that these kitchen cabinets deliver both visual appeal and practical performance, making them the preferred choice for contemporary projects.

3. How Casta Adds Value to American Standard Cabinetry Principles

Casta Cabinetry stands out for its commitment to excellence in producing American standard cabinets. With over 20 years of experience, they combine advanced technology and sustainable practices to deliver products that consistently exceed expectations.

3.1 Advanced Production Facility

- State-of-the-Art Technology:

Casta’s Vietnam facility is equipped with cutting-edge European machinery, ensuring that every cabinet is manufactured with precision. This technology results in tight tolerances (as low as 0.1%) and minimal waste, which is key to producing high-quality American standard kitchen cabinets.

Major Investments:

- €6 million invested in SCM production machinery

- $1 million SAP software implementation for end-to-end process control and efficiency

The facility benefits from a substantial investment of over 6 million euros in SCM production machinery and SAP ERP software valued at 1 million USD. This investment enhances production efficiency, streamlines operations, and maintains stringent quality standards.

- ERP Integration & Automation:

The facility leverages advanced ERP systems and automatic production lines to synchronize design, production, and inspection processes. This integration limits manual errors and optimizes production time by up to 30%, ensuring a streamlined workflow and consistent product quality.

- Innovation & Research:

Continuous investment in R&D and digital tools (including ERP systems) drives process improvements and helps Casta stay at the forefront of cabinetry production.

Learn more: Casta’s OEM Cabinet Manufacturer

- Quality Control:

Every cabinet undergoes rigorous testing and inspection, guaranteeing that it meets strict industry standards and performs reliably over time.

3.2 Customization & Design Excellence

- Tailored Solutions:

Through an iterative design process—typically 3–5 rounds—Casta offers bespoke customization options that transform standard dimensions into perfectly tailored cabinets.

Learn more: Casta’s Ideal Custom Cabinets

- Seamless Integration:

Their designs integrate effortlessly into various settings, whether in upscale residential projects or commercial developments, providing both functionality and style.

- Customer Satisfaction:

Casta’s personalized approach and commitment to quality have earned them a reputation for delivering American standard cabinets that consistently exceed client expectations.

Learn more: Casta’s Outstanding International Projects

3.3 Commitment to Certification & Health Standards

- Certified Materials:

Casta sources its wood and composite materials exclusively from certified suppliers in Vietnam, ensuring every product is made from eco-friendly and sustainable resources.

- Global Compliance:

Adherence to certifications like CARB, FSC, and ISO confirms that each cabinet is built to the highest environmental and safety standards.

CARB Phase 2

- Benefit: Limits formaldehyde emissions to ≤0.05 ppm, ensuring healthier indoor air quality

- Why It Matters: Meets California air-quality regulations and most North American requirements, reducing off‑gassing and liability concerns

FSC (Forest Stewardship Council)

- Benefit: Guarantees wood and veneers come from responsibly managed forests

- Why It Matters: Demonstrates sustainability, appeals to eco‑conscious clients, and enhances brand reputation

ISO 9001 Quality Management

- Benefit: Provides a framework for consistent manufacturing processes and continuous improvement

- Why It Matters: Reduces defects, ensures uniform quality across every batch of cabinets, and meets global quality expectations

- Assured Quality:

Rigorous third-party audits and continuous quality checks ensure that all American standard cabinets meet or exceed international benchmarks.

Learn more: Casta’s ISO-Qualified Cabinet Certification: Setting the Gold Standard for Quality and Reliability

3.4 Proven National Success

- Consistent Excellence:

Casta’s portfolio includes numerous successful projects across major U.S. cities, demonstrating that their American standard kitchen cabinets deliver consistent quality and performance.

- 500+ projects completed nationwide

- 150,000+ apartment units fitted

- 100+ hospitality venues supplied

Projects such as 99 PRATT in Hartford, THE GRANARY in Fort Collins, THE ETHAN in Columbus, Liberty Tower in Chicago, The Parkview Residence in Miami, and Heritage Office Complex in San Francisco showcase how industry leaders trust Casta's cabinetry. These projects span upscale residential renovations, high-profile commercial developments, and modern office spaces, reinforcing Casta’s reputation as a dependable supplier.

- Reliable Partnerships:

Their proven track record has built trust among contractors and developers who rely on Casta for timely, high-quality installations.

- Scalability:

With large-scale production capabilities, Casta can handle bulk orders without sacrificing quality, ensuring every project receives premium American standard cabinets.

Learn more: Casta’s Outstanding International Projects

By combining advanced production methods, robust quality control, bespoke customization, and rigorous certification, Casta Cabinetry sets the gold standard in standard cabinetry. Their approach not only delivers exceptional performance and aesthetic appeal but also ensures that every project benefits from sustainable, eco-friendly practices.

4. Market Trends & Consumer Demand Analysis

The market for American standard cabinets is evolving rapidly. As sustainability, durability, and precision become ever more critical, contractors and furniture brands are demanding products that not only meet strict standards but also deliver consistent performance and aesthetic appeal.

4.1 Industry Data & Growth Projections

- Rising Demand:

Recent research indicates robust annual growth in the U.S. cabinet manufacturing sector. With the global furniture market set to expand over the next few years, demand for high-quality, standardized cabinetry is increasing. This trend is fueled by the surge in residential construction, home renovations, and commercial projects that require uniform, dependable products.

- Certified Products on the Rise:

There is a growing shift toward products made from eco-friendly and certified materials. Manufacturers are increasingly using low-emission, sustainable resources—helping drive the popularity of American standard kitchen cabinets among eco-conscious buyers.

- Economic Impact:

Advancements in manufacturing techniques have led to more cost-effective production processes. As a result, the market for American standard cabinets is expected to offer durable, affordable solutions that appeal to both large-scale projects and boutique designs.

4.2 Consumer Behavior & Contractor Preferences

- Customization & Efficiency:

Projects incorporating customizable standard cabinetry experience fewer delays and lower maintenance costs. Contractors value the efficiency and consistency that American standard cabinets provide, which helps streamline installations and reduce project disruptions. A recent survey found that 78% of U.S. consumers are willing to pay 15–25% more for custom kitchen cabinets built with FSC-certified materials, underscoring the strong market demand for personalized and eco-friendly solutions.

- Long-Term Partnerships:

High satisfaction with product quality and reliability fosters repeat business. Contractors and developers appreciate that American standard kitchen cabinets consistently deliver on performance, leading to long-term supplier relationships.

Learn more: Success Stories: US Companies Thriving with Vietnamese Cabinet and Furniture Manufacturers

- Focus on Sustainability:

With a growing emphasis on green building practices, consumers and brands are increasingly selecting furniture made from eco-friendly materials. This sustainability focus is driving the market toward products that not only perform well but also contribute to environmental stewardship.

4.3 Competitive Landscape & Differentiators

Below is an expanded comparison of the key features of American standard cabinets versus other cabinet options. This detailed analysis highlights why standard cabinets are preferred by many contractors and furniture brands for their consistent performance, quality, and sustainability.

| Feature | American Standard Cabinets | Other Cabinet Options |

| Material Quality | Constructed with premium, certified materials (e.g., FSC/PEFC wood, eco-friendly engineered panels) that ensure long-term durability and consistent performance. | Often produced with lower-grade materials that may exhibit inconsistent quality and lower durability. |

| Customization | Employ an extensive, iterative design process (typically 3–5 rounds) that allows for tailored dimensions, finishes, and configurations to meet specific project needs. | Generally offer limited customization options, resulting in a one-size-fits-all approach. |

| Manufacturing Precision | Utilize advanced European machinery that achieves cutting tolerances as fine as 0.1%, ensuring uniformity and reducing material waste. | Rely on traditional production methods, which can lead to variability in size, finish, and overall quality. |

| Certifications | Strictly adhere to global standards such as CARB, FSC, and ISO, providing documented assurance of health, safety, and environmental compliance. | Certification levels can vary significantly, with some suppliers lacking the rigorous standards required for high-end applications. |

| Delivery Reliability | Benefit from a robust, well-coordinated logistics network that guarantees over 98% on-time delivery, critical for meeting project deadlines. | Delivery schedules can be inconsistent, leading to potential project delays and increased coordination challenges. |

| Sustainability | Sourced from eco-friendly, renewable resources with a focus on sustainable production practices that reduce environmental impact. | Often have less emphasis on sustainability, which may result in higher environmental footprints and non-compliance with green building standards. |

This comprehensive table demonstrates that American standard cabinets offer clear advantages in material quality, design flexibility, manufacturing precision, and sustainability. These factors make them an ideal choice for high-demand projects where performance, reliability, and eco-friendly practices are paramount.

Contractors and brands seeking to deliver superior, cost-effective, and long-lasting cabinetry solutions will find that standard cabinets provide the optimal blend of innovation and practicality.

4.4 Future Trends & Innovation

- Automation & Smart Materials:

Advancements in automation and the integration of smart materials are set to further enhance production efficiency. AI-driven design tools will optimize material use and reduce waste, paving the way for even more refined American standard kitchen cabinets. For example, platforms like Autodesk Fusion 360 with its generative design capabilities, TensorFlow-based predictive analytics, and computer vision systems are being integrated into manufacturing workflows. These tools analyze design parameters, optimize material use, and reduce waste by simulating stress conditions and identifying inefficiencies in real time. This integration paves the way for even more refined American standard kitchen cabinets, delivering improved performance and sustainability.

- Evolving Design Standards:

As consumer tastes evolve, design standards for standard cabinets will continue to be refined. These innovations will drive improvements in both aesthetics and functionality, ensuring that modern cabinets remain contemporary and durable.

- Sustainability & Regulation:

With stricter environmental regulations on the horizon, manufacturers will be compelled to adopt even greener practices. The continued integration of sustainable materials in cabinet production is expected to become a key differentiator, further driving market growth.

- Global Market Expansion:

As the demand for eco-friendly, reliable cabinetry grows, suppliers who produce American standard cabinets efficiently will capture a larger share of the global market, particularly in North America and Europe.

5. U.S. Projects & National Impact

Casta Cabinetry’s commitment to precision, durability, and tailored design is clearly reflected in its U.S. project portfolio. These projects demonstrate how their high-quality cabinets consistently meet strict American standards while delivering measurable benefits in efficiency, functionality, and visual appeal.

5.1 99 PRATT – Hartford, CT, USA

a. Overview:

Located in Hartford, CT, the 99 PRATT project is a custom cabinetry solution designed for commercial development. This installation was created to adhere to rigorous American design standards while offering durability and refined aesthetics.

b. Approach & Execution:

- Materials & Design:

- Utilized premium, certified solid wood and eco-friendly engineered panels to ensure long-term performance and environmental compliance.

- Incorporated design elements that reflect precise dimensions and consistent finishes.

- Precision Manufacturing:

- Leveraged advanced European machinery at the Vietnam facility to achieve cutting tolerances as low as 0.1%, ensuring a flawless fit and finish.

- Customization:

- Engaged in multiple design rounds with the client to tailor cabinet dimensions and finishes to meet specific commercial requirements.

c. Results:

- Efficiency Gains:

- Installation time was reduced by 20%, leading to smoother on-site coordination and faster project completion.

- Longevity:

- Cabinets are projected to last over 20 years with minimal maintenance, ensuring sustained performance.

- Client Feedback:

- The client praised the consistent quality and refined aesthetics of these high-standard cabinets.

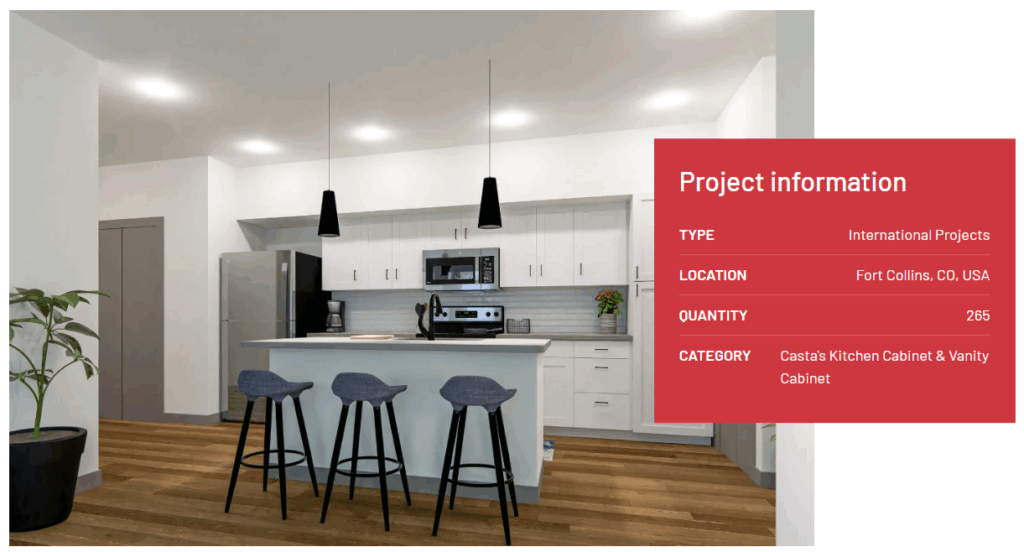

5.2 THE GRANARY – Fort Collins, CO, USA

a. Overview:

THE GRANARY is a bespoke cabinetry installation for a mixed-use development in Fort Collins, CO. The project seamlessly blends modern functionality with a timeless design, meeting the highest American standards.

b. Approach & Execution:

- Materials & Design:

- Employed FSC-certified solid wood alongside eco-friendly engineered panels to ensure robust performance and sustainability.

- Focused on achieving both aesthetic elegance and structural strength.

- Precision Manufacturing:

- Used state-of-the-art European machinery to produce consistent and high-quality cabinets with minimal waste.

- Customization:

- Worked closely with developers to refine design details through iterative consultations, ensuring the final product perfectly addressed unique spatial and aesthetic needs.

c. Results:

- Enhanced Functionality:

- Improved workspace organization with reduced maintenance issues due to precision engineering.

- Durability:

- Cabinets built to withstand heavy use, with an anticipated lifespan exceeding 20 years.

- Client Feedback:

- Praised for timely delivery, exceptional craftsmanship, and superior visual appeal that meets the demands of modern commercial environments.

5.3 THE ETHAN – Columbus, OH, USA

a. Overview:

THE ETHAN is a custom cabinetry project located in Columbus, OH. Serving both residential and commercial segments, the project exemplifies strict adherence to American standards through meticulous design and craftsmanship.

b. Approach & Execution:

- Materials & Design:

- Integrated premium certified solid wood with low-VOC engineered panels to ensure superior indoor air quality and lasting durability.

- Designed with a focus on both elegance and functionality.

- Precision Manufacturing:

- Employed advanced European machinery to achieve meticulous production standards and efficient material utilization.

- Customization:

- Implemented an iterative design review process, ensuring that each cabinet was precisely tailored to diverse spatial requirements and design preferences.

c. Results:

- Operational Efficiency:

- Streamlined installation processes resulted in significant time and cost savings.

- Long-Term Durability:

- Cabinets are engineered to serve for over 20 years with minimal maintenance, ensuring sustained performance.

- Client Feedback:

- The project received high praise for its exceptional quality, attention to detail, and enhanced functionality, which elevated the overall design of the space.

Casta Cabinetry’s U.S. project portfolio is a testament to the superior quality and reliability of their products. Their installations across Hartford, Fort Collins, and Columbus demonstrate that adherence to strict American standards results in cabinetry that is not only aesthetically pleasing but also exceptionally functional and durable. These projects highlight key benefits such as:

- Efficiency Gains: Faster installations and reduced project timelines.

- Long-Term Durability: Products designed to last over 20 years with minimal upkeep.

- Enhanced Aesthetics: Modern, refined designs that elevate any space.

- Customer Satisfaction: Consistent quality and reliable delivery that build lasting client trust.

For contractors, cabinet brands, and furniture companies aiming to enhance project performance and ensure lasting quality, partnering with a trusted manufacturer like Casta Cabinetry is essential.

6. Final Takeaways & Next Steps

American standard cabinets are revolutionizing furniture manufacturing by delivering unmatched precision, durability, and safety. American standard cabinets utilize premium materials and adhere to strict industry standards, ensuring that each American standard cabinet offers exceptional performance and ease of installation. These American standard cabinets, including American standard kitchen cabinets, are produced by manufacturers like Casta Cabinetry, who leverage advanced European machinery and sustainable practices to set the benchmark for quality and reliability.

For contractors, cabinet brands, and furniture companies, choosing these high-quality cabinets means investing in dependable, eco-friendly solutions that drive project success and contribute to a greener future.

Explore our range of American standard cabinets and discover how our innovative manufacturing techniques can elevate your next project. Contact us today to learn more.

7. Frequently Asked Questions (FAQ)

What exactly are American standard cabinets?

How do American standard cabinets differ from other cabinet options?

What sustainable materials are used in American standard cabinets?

How does Casta ensure the quality of its American standard cabinets?

Can I customize American standard cabinets for my project?

Top Cabinet Manufacturers in Florida: A Capability-Based Buy...

Cabinet manufacturers in Florida play a critical role in one of the fastest-growing construction markets in North Americ...

01/10/2026 | David Nguyen

Top North Carolina Cabinet Manufacturers | Best NC Kitchen ...

North Carolina cabinet manufacturers have long been trusted across the U.S. thanks to the state’s deep heritage in woodw...

01/08/2026 | David Nguyen

Top Cabinet Manufacturers in Arizona | Best Arizona Kitchen ...

Cabinet manufacturers in Arizona have gained increasing attention as construction activity accelerates across Phoenix, T...

01/06/2026 | David Nguyen

Top Cabinet Manufacturers Indiana | Best Indiana Kitchen Cab...

Cabinet manufacturers Indiana have become increasingly relevant as contractors and developers look for dependable Midwes...

01/04/2026 | David Nguyen

Contact us

Casta is always ready to listen and answer all customers' questions