Glass front cabinet doors have surged in popularity across modern kitchen and cabinetry programs, offering contractors and brands a way to blend transparency, light diffusion, and display opportunities into their designs. Whether you’re specifying glass front kitchen cabinets in a high-end multi-family development or integrating glass front wall cabinets into a boutique hospitality fit-out, the right configuration elevates perceived value and enhances spatial brightness. This guide presents 20 on-trend glass front cabinet ideas—complete with use cases, materials, and sourcing strategies—to help contractors, furniture brands, and cabinet companies excel in 2025.

Table of Contents

1. Market Insights: Who’s Using Glass Front Cabinets in 2025

Glass front cabinets are no longer confined to luxury kitchens; they’re mainstream in both mid-range and premium projects:

- High-End Segments: Luxury multifamily buildings, boutique hotels, and custom homes now feature glass front kitchen cabinets with frosted or tinted glass fronts to maximize light flow and showcase curated dishware.

- Mid-Range Projects: Urban apartments and townhomes in California, Texas, and Florida frequently include reeded or partial glass front cabinet doors to deliver an “open concept” feel without sacrificing privacy.

- Regional Trends:

- West Coast: Frameless glass front wall cabinet designs with push-to-open hardware dominate minimalist and Japandi interiors in LA and San Francisco.

- East Coast: Frosted or shaker-style glass front cabinet doors are popular in suburban renovations across New York and New Jersey.

- Southern U.S.: Bronze-tinted glass fronts in oak frames lend warmth to transitional kitchens in Texas and Florida.

With improved manufacturing efficiencies, glass front cabinet features are now scalable across retail-ready and modular cabinetry lines.

2. Key Advantages of Glass Front Cabinets in B2B Projects

2.1 Aesthetic Enhancement

- Breaks up solid expanses: Incorporates glass front cabinet doors to create visual vignettes.

- Showcases décor: Perfect for displaying fine dinnerware, branded products, or art pieces.

- Luxury perception: Upgrades showroom appeal in glass front kitchen cabinets without dramatically increasing cost.

2.2 Increased Light & Visual Space

- Reflects light: Transparent or frosted inserts in glass front wall cabinet units bounce natural and artificial light deeper into rooms.

- Opens small areas: Prevents tunnel vision in pantries and corridors by offering sightlines into cabinet interiors.

- Illuminated displays: Backlit glass fronts enhance brightness and draw attention to key storage zones.

2.3 Adaptability to Many Design Styles

- Modern to traditional: Choose frameless clear-glass slabs for minimalist kitchens or shaker-style frames with mullions for classic appeal.

- Material flexibility: Compatible with wood veneer, aluminum, or powder-coated frames—ideal for industrial lofts, transitional spaces, or Japandi interiors.

- Coordinated collections: Standardize glass front cabinet modules across varied product lines to streamline SKUs and simplify installation.

Learn more: The Ultimate Guide to Modern Design Kitchen Cabinets

2.4 Cost-Efficient Upsell Opportunity

- Premium look, modest premium: Glass front kitchen cabinets carry only a 15–25 % price increase over solid doors yet deliver significant visual impact.

- Tiered product lines: Position as a “next-level” upgrade in mass-market catalogs to boost average order value.

- Higher margins: Leverage the perceived luxury of glass front cabinet doors to improve project profitability.

2.5 Customization Potential for OEM Brands

- Glass variety: Clear, frosted, reeded, tinted, or etched options to match each brand’s design language.

- Frame and hardware: Select wood, metal, or composite frames and coordinate handles or push-to-open systems.

- Brand consistency: Roll out custom glass front wall cabinet SKUs that align with existing door collections, ensuring a cohesive portfolio.

Learn more: Top rated cabinet manufacturers

3. 20 Glass Front Cabinet Ideas with Use Cases and Descriptions

Before diving into our 20 inspiring glass front cabinet concepts, it’s crucial to understand the key criteria that make these designs stand out in real-world applications:

- Aesthetic Impact: How the glass front cabinet doors complement overall interior style—modern, industrial, transitional, or classic.

- Functionality & Visibility: The balance between display and concealment—with options like clear, frosted, or reeded glass—to showcase dishware or provide privacy.

- Material & Durability: Frame materials (aluminum, MDF, solid wood) and glass types (tempered, laminated, acid-etched) that meet project specifications for safety and longevity.

- Ease of Maintenance: Surfaces and hardware that resist fingerprints, scratches, and simplify cleaning in high-traffic kitchens or hospitality settings.

- Cost & Scalability: Designs that fit budget tiers—from minimalist frameless units to luxurious etched-glass solutions—while supporting OEM/ODM customization and flat-pack logistics.

With these factors in mind, explore the following glass front cabinet ideas—each paired with ideal use cases, technical details, and positioning advice to help contractors and cabinet brands confidently specify the perfect glass front wall cabinet or glass front kitchen cabinets for any project.

Modern & Minimalist Designs (1–5)

- Frameless Full-Glass Slab Doors

- Use Case: Sleek urban model kitchens seeking a gallery-like display.

- Details: 6 mm tempered clear glass, UV-bonded to ultra-thin aluminum edges for an all-glass aesthetic.

- Positioning: High-end condo packages, where homeowners value unbroken sightlines.

- Why It Works: Eliminates visible frame interruptions for a truly minimalist feel—perfect when specifying glass front cabinet door styles that maximize openness.

Learn more: Frameless Cabinets vs Full Overlay: Which Is Right for You?

- Matte Black Aluminum Frames with Clear Glass

- Use Case: Industrial loft kitchens and contemporary showroom vignettes.

- Details: 25×15 mm powder-coated aluminum profiles with 5 mm clear glass, welded corners.

- Positioning: Urban condo developments and tech-forward residential lines.

- Why It Works: The contrast of matte black frames and glass highlights clean geometry—an eye-catching glass front wall cabinet style for modern interiors.

- Push-to-Open Glass Doors with Lacquered Frames

- Use Case: Handle-less contemporary kitchen lines focused on seamless design.

- Details: High-gloss lacquer MDF frames, frosted 6 mm glass, integrated push-to-open hardware.

- Positioning: European-inspired kitchen collections and premium RTA offerings.

- Why It Works: Combines the sleekness of glass front cabinet doors with fingerprint-resistant lacquer for a luxury hands-free experience.

- Floating Glass Upper Cabinets

- Use Case: Space-saving minimalist layouts in small urban apartments.

- Details: Hidden stainless-steel mounting brackets, tinted 5 mm safety glass, anti-sag shelf supports.

- Positioning: Premium flat-pack kitchen systems and co-living developments.

- Why It Works: Creates a “floating” effect that enhances visual space and showcases curated items behind clear glass.

- High-Gloss Painted MDF + Glass Front Panels

- Use Case: Transitional urban homes balancing display and solid storage.

- Details: 18 mm MDF doors with inset 4 mm fused glass panels, UV-cured lacquer finish in trending jewel tones.

- Positioning: Trendy apartment developments and small-luxury home lines.

- Why It Works: Allows for versatile flat panel cabinet door styles, mixing opaque and transparent finishes to highlight feature areas.

Transitional & Warm Style Concepts (6–10)

- Shaker Frame with Frosted Glass Inserts

- Use Case: Suburban remodels blending tradition and openness.

- Details: 5 mm frosted safety glass set into 18 mm MDF shaker frames, soft-close hinges.

- Positioning: Mid-range housing developments seeking a transitional glass front kitchen cabinets look.

- Why It Works: Retains classic shaker charm while introducing a modern twist with frosted glass—ideal for styles of glass front door cabinets.

Learn more: Shaker style cabinets

- Natural Oak Veneer Frame + Bronze-Tinted Glass

- Use Case: Warm transitional kitchens and eco-conscious builds.

- Details: FSC-certified oak veneer over plywood frame, 6 mm bronze-tinted tempered glass.

- Positioning: High-end eco homes and Japandi-inspired lines.

- Why It Works: The warm wood tone and subtle tint provide privacy while allowing ambient glow—an upscale glass front cabinet door style.

- Two-Tone Layout with Glass-Front Uppers

- Use Case: Show model homes and designer portfolios.

- Details: Matte-finish MDF base cabinets paired with high-gloss or tinted glass-front uppers, concealed LED strip lighting.

- Positioning: Upscale residential developments emphasizing contrast.

- Why It Works: Draws the eye upward and creates visual interest through color and transparency—perfect for glass front wall cabinet feature sections.

- Half-Panel Glass Doors

- Use Case: Family kitchens balancing display and concealed storage.

- Details: Lower solid panel in painted MDF, upper 4 mm etched glass for semi-privacy.

- Positioning: Multi-family developments and entry-level luxury units.

- Why It Works: Offers a compromise between full transparency and complete concealment, ideal for glass front kitchen cabinets in high-traffic homes.

- Flat Panel Frames with Reeded (Textured) Glass

- Use Case: Japandi, Scandi, or soft-modern interiors seeking subtle diffusion.

- Details: Soft-touch matte frames with thick reeded pattern glass allowing light diffusion.

- Positioning: Contemporary minimal homes and boutique retail spaces.

- Why It Works: Reeded glass hides clutter while still sharing a glimpse of the contents—an elegant glass front cabinet door style.

Learn more: Kitchen cabinet trends 2025

Luxury & Custom Hospitality Ideas (11–15)

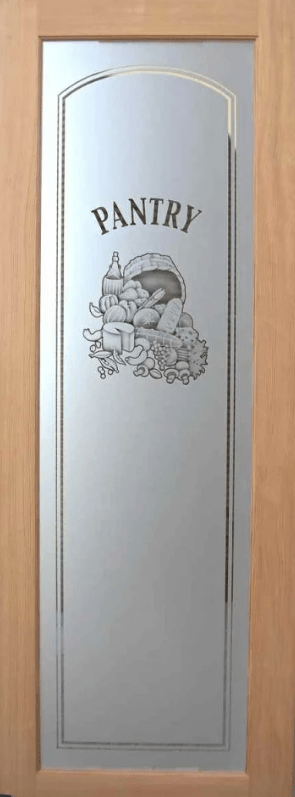

- Etched Glass Panels with Custom Logo

- Use Case: Branded hotel suites and upscale retail spaces.

- Details: Acid-etched tempered glass with inlaid logo designs, set in walnut veneer frames.

- Positioning: Boutique hospitality millwork and corporate lobbies.

- Why It Works: Combines brand identity with transparency—perfect for forging a memorable glass front cabinet signature.

- Curved Glass End Cabinets

- Use Case: Luxury villa kitchens and high-end yacht galleys.

- Details: Laminated curved safety glass molded to cabinet end panels, reinforced backing frames.

- Positioning: Ultra-luxury residential and bespoke marine interiors.

- Why It Works: Adds organic softness and bespoke craftsmanship to glass front kitchen cabinets, accentuating premium spaces.

- Gold-Framed Doors with Clear Glass

- Use Case: Premium showrooms and penthouse kitchens.

- Details: Anodized gold aluminum frames paired with 5 mm clear tempered glass and glass shelving.

- Positioning: Luxury hospitality suites and upscale residential show flats.

- Why It Works: The metallic frame adds a statement of opulence—ideal when premium glass front cabinet door styles are needed.

- Arch-Top Framed Cabinets with Transparent Glass

- Use Case: French-inspired country kitchens and grand restorations.

- Details: Solid wood arch-top frames, 4 mm clear tempered glass, decorative mullions.

- Positioning: Custom heritage builds and luxury estates.

- Why It Works: Combines classic curves with transparent panels—offering an elevated glass front cabinet solution.

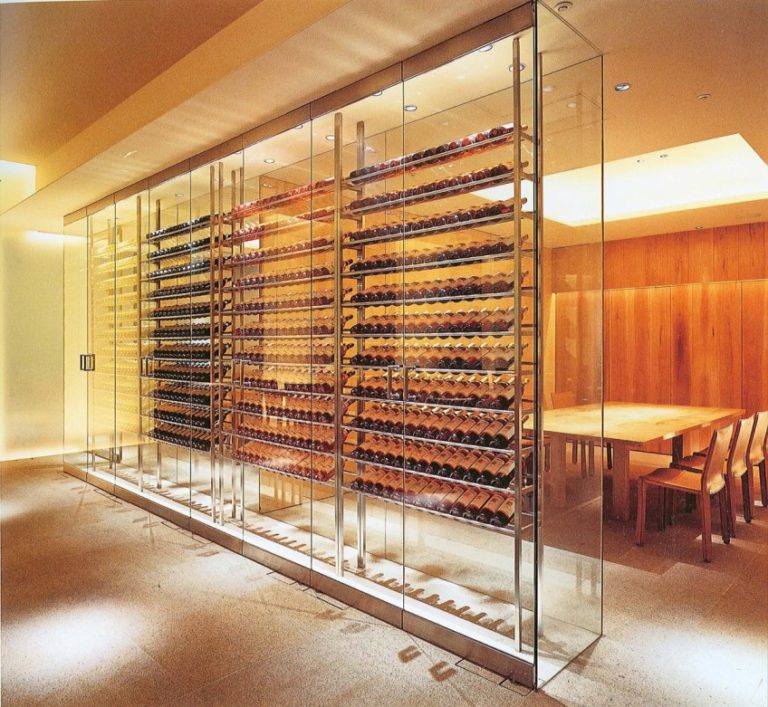

- Lockable Glass Wine Cabinets with Lighting

- Use Case: Wet bars, tasting rooms, and entertainment centers.

- Details: Smoked tempered glass door with integrated lock, interior LED shelf lighting, wine-racking inserts.

- Positioning: High-end home bars and boutique restaurant backbars.

- Why It Works: Merges security and display—showcasing valuable collections behind glass front cabinet doors.

Learn more: Best custom cabinet manufacturers

Functional Display Applications (16–20)

- LED-Lit Display Cabinets

- Use Case: Showrooms and designer residences.

- Details: Diffused toughened glass panels, under-shelf LED strips, back-painted glass interiors.

- Positioning: Designer homes and concept kitchens.

- Why It Works: Illuminates cookware and collectibles—turning glass front cabinet storage into an exhibit.

- Sliding Glass Pantry Cabinet Doors

- Use Case: Space-constrained urban kitchens and studios.

- Details: Soft-close aluminum tracks, frosted safety glass panels, recessed pulls.

- Positioning: Modular and RTA kitchen systems.

- Why It Works: Saves swing space while maintaining a glass front kitchen cabinet aesthetic in tight layouts.

- Glass Office Storage Cabinets with Locks

- Use Case: Home offices and commercial workspaces.

- Details: Laminated clear glass, integrated locksets, melamine-lined interiors.

- Positioning: Hybrid work setups and B2B office fit-outs.

- Why It Works: Blends storage security and display—perfect for showcasing binders and branded materials behind glass front cabinet doors.

- Corner Cabinet Glass Inserts with Interior Lighting

- Use Case: L-shaped kitchen corners and awkward nooks.

- Details: 45° glass insert panels, warm white LED tape, glass shelving.

- Positioning: Custom residential renovations and designer kitchens.

- Why It Works: Activates dead space—turning corner areas into illuminated displays within glass front wall cabinets.

- Slim Glass Panels in Floating Entry Cabinets

- Use Case: Entryways and multi-use zones in co-living developments.

- Details: 3 mm frosted glass strips set in floating cabinet frames, matte paint finish.

- Positioning: Rental-ready modular furniture lines and lobby installations.

- Why It Works: Adds elegant transparency to storage without bulk—showcasing essentials behind a glass front cabinet facade.

Learn more: Industrial Cabinets Made in Vietnam: Durability and Functionality for Demanding Applications

4. Technical Considerations for Glass Cabinet Manufacturing

When specifying glass front cabinet doors or full glass front kitchen cabinets, understanding these technical parameters ensures quality, compliance, and durability. Below is a detailed overview of each critical feature:

| Feature | Options / Details |

| Glass Types | • Tempered Glass: Heat-treated for 4× greater strength; shatters into blunt granules—ideal for safety in glass front wall cabinet applications. • Laminated Glass: Two panes bonded with PVB interlayer; holds fragments on breakage; suited for high-traffic kitchens. • Frosted Glass: Acid-etched or sandblasted for privacy; diffuses light—perfect for semi-transparent glass front cabinet inserts. • Reeded Glass: Textured vertical ribs obscure contents; adds privacy while allowing light—common in Scandi-style and Japandi fits. • Tinted Glass: Bronze, smoke, or grey tints reduce glare and add warmth—elegant in transitional glass front kitchen cabinets. • Etched/Acid-Etched: Custom patterns, logos, or artwork permanently etched into the surface for branding or decorative accents. |

| Frame Materials | • Solid Wood: Maple, oak, walnut frames around glass panels—premium look but requires moisture control to prevent warping. • Aluminum: Lightweight, corrosion-resistant frames in powder-coated or anodized finishes—used in modern-industrial glass front cabinet door styles. • Veneered MDF: Cost-effective wood-grain veneer over stable MDF core; prevents expansion/contraction issues common in solid wood. • Powder-Coated Steel: Ultra-durable frames in bold colors or metallics; ideal for high-use commercial and retail glass front wall cabinets. |

| Surface Finishes | • Lacquer (Gloss/Matte): UV-cured lacquer for high-gloss shine or soft matte texture—commonly used on frames adjacent to glass. • Melamine: Factory-fused melamine on MDF frames for scratch/corrosion resistance—good for contract-grade glass front cabinet units. • Veneer: Thin, real-wood veneer offers authentic grain with lower cost and improved stability over solid wood. • Acrylic Overlay: High-gloss acrylic sheets laminated to substrates for reflective surfaces in glass front kitchen cabinets. |

| Certifications | • CARB Phase 2: Ensures formaldehyde emissions ≤0.05 ppm—mandatory for panels sold in California and many U.S. states. • E1 (EU Standard): Limits total VOCs to ≤0.1 ppm—recognized globally for indoor air-quality. • FSC-Mix Credit: Verifies responsible sourcing of wood fibers—important for eco-friendly glass front cabinet doors. |

| Manufacturing Notes | • CNC Cutting: Precision routing of glass grooves and frame profiles—tolerance ±0.1 mm ensures consistent fit for glass front wall cabinet assemblies. • Sealed Routing: Edges of routed MDF or wood frames sealed with water-resistant primer to prevent moisture ingress. • Edge Banding: ABS, PVC, or wood veneer banding applied to exposed substrate edges for clean transitions between glass and frame. • Glass Adhesive Bonding: Specialized silicone or structural adhesives bond glass to frames without visible fasteners, maintaining a sleek glass front cabinet aesthetic. |

| Pros / Cons | Pros: – Enhances visual openness and premium look – Reflects and diffuses light, brightening interiors – Showcases curated items, adding merchandising value Cons: – Higher manufacturing complexity and equipment costs – Increased fragility and weight during shipping—requires robust packaging – Additional certifications and handling protocols add lead time |

Why These Details Matter for Your Projects

- Safety & Compliance: Selecting the right glass front cabinet type and ensuring CARB/E1 certification protects both occupants and your warranty obligations.

Learn more: Non toxic kitchen cabinets

- Durability: Proper frame material and finish choice prevents warping, peeling, or delamination in high-humidity kitchens.

Learn more: Material & Finish Innovations: Elevating Cabinet Design and Durability

- Aesthetic Consistency: Consistent CNC tolerances and adhesive bonding methods maintain uniform reveal widths and clean sightlines across all glass front kitchen cabinets.

- Logistics: Understanding fragility and weight helps contractors plan packaging and installation, reducing breakage claims and downtime.

Learn more: Lead Times & Supply Chain Resilience: Navigating Potential Disruptions

By integrating these technical considerations into your specifications, you’ll deliver glass front cabinet door styles that look stunning, perform reliably, and meet modern health, safety, and sustainability standards.

5. Why Glass Cabinets Work for Brands & Large-Scale Projects

5.1 Easy to Scale for Standard or Premium Lines

- Modular Integration: Glass front cabinet inserts fit into existing frameless or framed carcass systems without altering box dimensions—allowing seamless addition to standard or premium product lines.

- Consistent Quality: CNC precision ensures each glass front kitchen cabinet module meets exact tolerances, maintaining uniform reveal widths and hinge alignments across thousands of units.

- Tiered Offerings: Brands can offer a base solid-door model alongside a glass-front upgrade, leveraging the same carcass platform to cater to entry-level and luxury markets with minimal tooling changes.

5.2 Differentiation at Low Cost Increase

- Premium Perception: Adding a glass front cabinet doors option typically raises unit cost by only 15–25% yet conveys a significant luxury upgrade to end users.

- Higher Order Value: Data shows projects with optional glass fronts achieve a 12% higher average order value, as buyers perceive enhanced sophistication and display capability.

- Margin Expansion: With glass panel costs amortized over high-volume production, profit margins on glass front wall cabinet SKUs often outpace solid-door lines, boosting overall brand profitability.

5.3 Efficient for RTA/Flat-Pack Logistics

- Slim Profile Stacking: 4–6 mm glass panels laminated to thin frames stack flat with protective interlayers, optimizing container utilization and reducing freight charges by up to 20%.

- Durable Packaging: Custom foam inserts and reinforced corner protectors safeguard glass front cabinet panels during transit, reducing breakage claims by over 30% compared to traditional framed doors.

- Rapid Assembly: Pre-assembled glass-door modules require no onsite glazing—installers simply hinge or clip the complete glass front kitchen cabinets into place, cutting onsite labor by 25%.

Learn more: RTA kitchen cabinet manufacturers

5.4 Suitable for Many Markets

- Residential Kitchens: Enhances open-concept designs in urban lofts, transitional homes, and multi-family units with clear, frosted, or tinted glass front cabinet doors.

- Hospitality & Retail: Showcases barware, merchandise, and decorative pieces in hotel minibars, boutique shop fixtures, and restaurant service stations using illuminated glass front wall cabinets.

- Office & Institutional: Provides secure yet visible storage in corporate offices, educational facilities, and healthcare settings, leveraging lockable glass fronts for both privacy and display.

- Co-Living & Rental Lines: Offers aesthetic appeal without bulky profiles—ideal for modular glass front cabinet furniture in co-living spaces and turnkey rental flats.

By leveraging these scalable, cost-effective, and versatile benefits, cabinet brands and contractors can confidently integrate glass front cabinet options into large-scale production—driving differentiation, margin growth, and customer satisfaction across diverse market segments.

6. Why Source Glass Front Cabinets from Casta Cabinetry

When evaluating partners for glass front cabinet supply, reliability, quality, and scalability are paramount. Casta Cabinetry offers a compelling value proposition for brands and contractors seeking glass front kitchen cabinets at scale:

6.1 High-Precision Vietnamese Production

- Factory Scale & Capacity: With over 100,000 m² of manufacturing space across two sites, Casta Cabinetry can deliver thousands of glass front wall cabinet modules per month—meeting high-volume demands for multi-unit residential, hospitality, and commercial projects.

- Advanced Automation: Leveraging 90% automated processes, Casta minimizes manual handling of delicate glass front cabinet doors, reducing defects and ensuring consistent quality.

- State-of-the-Art Equipment: European CNC lines (HOMAG, Biesse, SCM) handle precise cutting of both frames and glass insets. Automated glass bonding stations and edge-banding units maintain ±0.1 mm tolerances—critical for seamless glass front cabinet integration.

6.2 Flexible OEM/ODM Services

- Custom Frame Materials: Choose solid wood, aluminum, veneered MDF, or powder-coated steel frames for your glass front kitchen cabinets, tailored to specific design themes and brand standards.

- Glass Options: Specify clear, frosted, reeded, tinted, or acid-etched glass inserts to achieve unique glass front cabinet door aesthetics—perfect for private-label collections or signature hospitality lines.

- Private-Label Production: Casta’s end-to-end OEM/ODM workflows handle CAD/BIM design, prototyping, and mass production—ensuring your glass front wall cabinet SKUs align with North American finish, dimension, and performance standards.

Sample Timeline: From Design Kickoff to Mass Production

| Stage | Activities | Duration |

| 1. Project Kickoff | Requirements gathering, frame material & glass option selection, initial timeline confirmation | 1 week |

| 2. CAD/BIM Design & Review | 3–5 iterative rounds of door/frame modeling, hinge/clip placement, and finish mock-ups | 2–3 weeks |

| 3. Prototype Fabrication | CNC cutting, edge banding, glass bonding of first-article sample of glass front cabinet doors | 1–2 weeks |

| 4. Sample Testing & Approval | Dimensional check, finish inspection, moisture & cycle testing, client sign-off | 1 week |

| 5. Tooling & Production Setup | Finalize toolpaths, jigs, and fixture setup for volume runs | 1 week |

| 6. Mass Production | Automated CNC, edge banding, glass insert installation, quality checks | 3–4 weeks |

| Total Estimated Lead Time | 9–12 weeks |

Note: Pilot batches and expedited services can compress this timeline by 1–2 weeks if required for tight launch schedules.

By following this structured process, your glass front kitchen cabinets and glass front wall cabinet SKUs move smoothly from concept to mass-market production—maintaining consistent quality while controlling lead times and the overall cost of soft close cabinets when integrating soft-close features.

Learn more: Casta’s ideal custom cabinets

6.3 Certified Health-Safe & Sustainable Materials

- CARB Phase 2 Compliance:

- Bid Specification: Mandate CARB Phase 2 compliance for all panel substrates (MDF, plywood, hardboard) and adhesives in your RFP or tender. This ensures that every bid meets California’s strict indoor air-quality standards, avoiding potential disqualification or post-award noncompliance issues.

- Supplier Selection: Prioritize vendors who provide mill test reports (MTRs) demonstrating CARB Phase 2 certification. Suppliers without documented CARB compliance expose projects to regulatory fines and mandatory rework—driving up the true cost of soft close cabinets or glass-front lines.

- E1 & FSC Certification:

- Bid Specification: Require E1 VOC ratings for any engineered wood used in exposed or semi-exposed applications, including glass front cabinet doors and hardboard cabinet backs. Combine this with an FSC Mix-Credit clause to verify that at least 70% of wood fibers come from responsibly managed forests.

- Supplier Selection: Vet suppliers by requesting Chain-of-Custody (CoC) certificates and E1 emission test data. Vendors lacking FSC or E1 credentials may not qualify for green building certifications (LEED, WELL), potentially weakening your bid in sustainability-focused tenders.

- Third-Party Verification:

- Bid Specification: Include a clause for independent third-party lab reports confirming tempered or laminated glass safety ratings (ANSI Z97.1, CPSC 16 CFR 1201) and moisture-resistant finish performance (ASTM D2247 humidity test) for glass front kitchen cabinets or hardboard panels.

- Supplier Selection: Favor suppliers whose products are routinely submitted to accredited labs for ongoing quality checks. This level of transparency boosts client confidence and minimizes onsite failures or warranty claims.

Learn more: Casta’s ISO-Qualified Cabinet Certification: Setting the Gold Standard for Quality and Reliability

6.4 Reliable Logistics & Delivery Support

- Predictable Lead Times: Typical door-to-port schedules range from 25–40 days, even for large orders of glass front cabinet modules—helping contractors adhere to tight construction timelines.

- Robust Packaging: Export-grade crates, foam inserts, and corner protectors safeguard fragile glass panels during ocean and air freight, reducing breakage claims by up to 30%.

- End-to-End Documentation: Casta bundles phytosanitary certificates, material test reports, customs paperwork, and real-time tracking in every shipment—streamlining customs clearance and field logistics for glass front cabinet door installations

Learn more: Casta’s outstanding international projects

7. Conclusion: A Versatile Cabinet Style That Drives Value

Glass front cabinets offer unmatched aesthetic versatility, seamlessly showcasing décor while maintaining storage functionality. By introducing glass front kitchen cabinets or glass front wall cabinet modules, contractors and brands can elevate any interior—from residential kitchens to boutique hospitality and retail displays—adding light, depth, and a premium feel without a prohibitive cost increase.

Moreover, glass front cabinet doors serve as a strategic upsell, boosting average order values and differentiating product lines. When paired with a manufacturing partner like Casta Cabinetry—renowned for precision-engineered processes, flexible OEM/ODM customization, and rigorous CARB/E1/FSC compliance—you can confidently integrate glass front cabinets into large-scale programs. This combination of style, performance, and profitability ensures your next project not only looks exceptional but also drives lasting value and competitive advantage.

8. FAQ

What types of glass are best for cabinet doors?

Can glass cabinets be used in wet areas?

Do glass cabinet doors cost significantly more?

Can I customize the glass and frame materials?

What certifications does Casta provide?

Top Cabinet Manufacturers in Florida: A Capability-Based Buy...

Cabinet manufacturers in Florida play a critical role in one of the fastest-growing construction markets in North Americ...

01/10/2026 | David Nguyen

Top North Carolina Cabinet Manufacturers | Best NC Kitchen ...

North Carolina cabinet manufacturers have long been trusted across the U.S. thanks to the state’s deep heritage in woodw...

01/08/2026 | David Nguyen

Top Cabinet Manufacturers in Arizona | Best Arizona Kitchen ...

Cabinet manufacturers in Arizona have gained increasing attention as construction activity accelerates across Phoenix, T...

01/06/2026 | David Nguyen

Top Cabinet Manufacturers Indiana | Best Indiana Kitchen Cab...

Cabinet manufacturers Indiana have become increasingly relevant as contractors and developers look for dependable Midwes...

01/04/2026 | David Nguyen

Contact us

Casta is always ready to listen and answer all customers' questions