The cabinet market trends are evolving rapidly, and among the materials available, MDF cabinets are emerging as a standout option for both contractors and cabinet/furniture brands. In today’s blog, we delve into the world of MDF cabinets—what is MDF cabinets, how MDF kitchen cabinets are made, and why many industry experts ask: is MDF good for cabinets? We’ll break down the composition, benefits, and limitations of MDF cabinets and provide practical guidance for making informed decisions in your next project.

Table of Contents

1. Why MDF Cabinets Are Worth a Closer Look

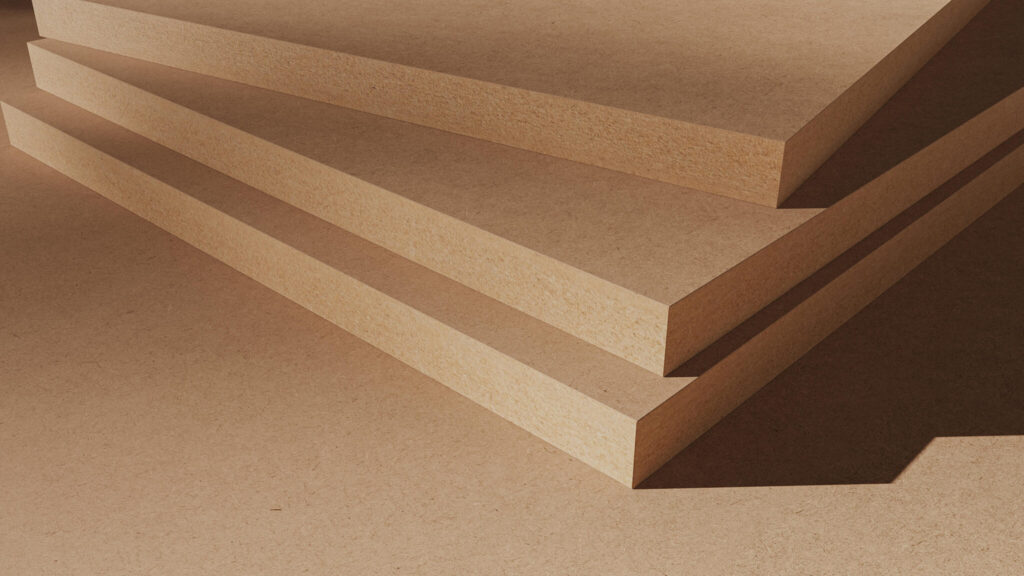

Medium-Density Fiberboard (MDF) has become a highly favored material in custom cabinetry because of its unique combination of affordability, consistency, and versatility. Produced by finely milling wood fibers and binding them with resin and wax under high pressure, this engineered wood product boasts a smooth, uniform surface that is ideal for a variety of finishes—whether it’s a solid-color paint, thermofoil, or laminate overlay.

Its homogeneous texture makes it especially popular for applications that demand precise customization and intricate detailing, as the absence of natural grain allows for cleaner cuts and more consistent results. Furthermore, MDF is relatively low cost compared to solid wood, coupled with its ability to minimize material waste during production, aligns well with modern market demands for both cost efficiency and sustainability.

In today’s competitive market, where both contractors and cabinet brands are under pressure to deliver high-quality, visually appealing products without exceeding budgets, understanding the technical attributes and performance of MDF is crucial. This comprehensive look at fiberboard-based cabinetry will explore the manufacturing process, key benefits, and inherent limitations of this material, providing essential insights for those in the custom cabinet industry and broader furniture sector.

2. What Are MDF Cabinets? A Technical Overview

2.1 What Is MDF?

MDF stands for Medium-Density Fiberboard. It is an engineered wood product composed of fine wood fibers, wax, resin, and binders. Processed under high heat and pressure, MDF results in dense, uniform panels with a smooth surface—ideal for painting and finishing. Typically, MDF has a density range of 600–800 kg/m³, making it a popular choice for cabinet manufacturing.

2.2 MDF Manufacturing Process

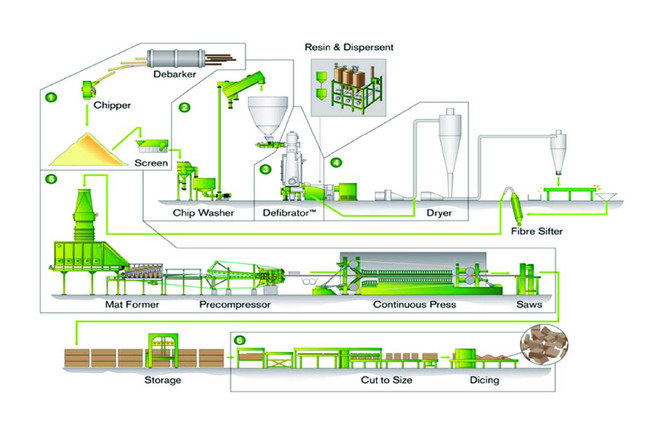

The manufacturing process for MDF cabinets is as follows:

- Wood Fiber Processing: Wood fibers are separated, screened, and refined for consistent quality.

- Drying and Resin Mixing: Fibers are dried and blended with resin and wax to create a uniform mat.

- Hot Pressing: The mat is hot‑pressed into large, dense sheets under controlled temperature and pressure.

- Sanding and Trimming: Sheets are sanded and trimmed to target thicknesses for cabinet use.

Automated production lines—including CNC routers, high‑capacity press machines, and automatic sanding systems—ensure tight tolerances and uniform density. This automation not only guarantees consistent, high‑quality panels but also enables contractors and brands to scale up orders quickly, reduce lead times, and minimize material waste.

2.3 Applications in Cabinet Manufacturing

MDF is a versatile material widely used in the custom cabinet industry. Common applications include:

- Door Fronts and Panels:

- The smooth, grain‑free surface of MDF is perfect for painted or thermofoil finishes, delivering a flawless, upscale look for residential and commercial cabinet doors.

- Use Case: Contractors specifying a uniform color palette across a high‑end kitchen showroom achieve consistent, repeatable results batch after batch.

- Shelving and Back Panels: Its uniformity ensures consistent quality across large-scale projects.

- MDF’s dimensional stability and uniform density ensure shelves and back panels remain flat and true, even in long runs or tall units.

- Use Case: Multi‑unit residential developers rely on MDF shelving in closet systems and pantry cabinets to maintain tight tolerances across hundreds of apartments.

- Interior Cabinetry Components: MDF is used in kitchen cabinets, bathroom vanities, storage units, and even in commercial millwork, reflecting strong cabinet market trends.

- Ideal for kitchen cabinets, bathroom vanities, and storage units, MDF supports a variety of hardware and soft‑close fittings.

- Use Case: Cabinet brands integrate MDF carcasses with custom face frames to balance cost‑efficiency and premium finishes in both RTA and fully assembled lines.

- Retail & Commercial Interiors:

- MDF panels are easily branded with paint, laminate, or vinyl overlays, enabling quick replication of store fixtures, display cases, and point‑of‑sale units.

- Use Case: National retail chains standardize on MDF‑based fixture modules for rapid roll‑out of new store layouts with exact color matching.

- Office & Hospitality Millwork:

- The material’s workability allows CNC‑generated integrated desks, shelving walls, and reception counters that require precise edge profiles and consistent paint finishes.

- Use Case: Hotel chains specify MDF for lobby millwork and guest‑room cabinetry, ensuring brand consistency and simplified maintenance.

- Modular & RTA Systems:

- Large MDF sheets enable efficient panelization for flat‑pack delivery, reducing shipping volumes and on‑site assembly time.

- Use Case: Co‑living developers choose MDF‑based modular kitchens to streamline installation across multiple sites, cutting labor costs and lead times.

2.4 Who Should Use MDF Cabinets?

MDF cabinets are ideal for:

- Contractors: Cost-efficient for large-scale projects, especially where a painted finish is preferred.

- Cabinet and Furniture Brands: Perfect for mass production and customizable designs, offering consistency and versatility.

- Residential and Commercial Developers: Suitable for interior applications such as kitchens, bathrooms, and offices, where a smooth finish and design flexibility are key.

- DIY Enthusiasts and Custom Designers: MDF is an excellent choice for bespoke projects on a budget, allowing for detailed customization.

Learn more: Sourcing Cabinets and Furniture from Vietnam: Your Ultimate Guide

3. 5 Key Benefits of MDF Cabinets for Contractors & Brands

MDF cabinets offer numerous advantages, which are driving positive cabinet market trends in the custom cabinet industry. Below are the five key benefits:

3.1 Lower Material Cost Without Sacrificing Finish

Insight: Project budgets consistently demonstrate a 15–25% overall cabinetry cost reduction when MDF is specified.

MDF panels typically cost 30–50% less than solid wood—around $15–$25 per 4’×8’ sheet versus $40–$60—while large sheet sizes reduce joints and scrap, improving yield by up to 20%. In multi‑unit residential builds, specifying MDF cabinets for 150 apartments can save developers over $40,000 on materials alone. For painted kitchen lines, MDF’s smooth, uniform surface requires fewer primer coats and less prep time, cutting finishing labor costs by 20% and delivering a flawless, high‑end look at a fraction of the expense. This blend of low material outlay and superior finish quality makes MDF cabinets a financially savvy choice in today’s cabinet market trends.

3.2 Excellent Surface for Paint & Coatings

Insight: Quality control records show paint defects on MDF cabinets occur less than 1% of the time, versus 5–7% on plywood alternatives.

The smooth, uniform surface of MDF is ideal for painted finishes. Whether you opt for a solid-color paint, thermofoil, or laminate overlay, MDF provides a flawless finish without the interference of natural grain, leading to superior aesthetic outcomes.

3.3 High Customization Potential

Insight: Production data shows lead times drop by 30% when switching from manual to CNC‑driven MDF workflows.

MDF lends itself to advanced, large‑scale production techniques that appeal to contractors and brands seeking precision and versatility:

- CNC Nested Machining: High-speed, multi‑axis CNC routers can process MDF panels in gang‑run nests, maximizing material yield and ensuring consistent tolerances (±0.2 mm) across hundreds of identical parts.

- Slab & Profile Styles: From clean slab‑style door faces and flat‑panel drawer fronts to intricate frame‑and‑panel or beadboard insets, MDF can be profiled with a wide array of edge treatments—ogee, bullnose, chamfer, and custom radius profiles—to suit any design aesthetic.

- 5-Axis Routing & Inlays: Complex curves, cutouts for integrated hardware, and decorative inlays are easily executed using 5‑axis CNC machining, enabling unique, brand‑specific details at scale.

- OEM/ODM Scalability: MDF’s uniform density allows rapid tooling changeovers for private‑label and bulk orders, streamlining production runs and reducing setup times while maintaining tight quality control.

- Finish Flexibility: Its smooth, grain‑free surface accepts painted, stained, laminated, or UV‑cured finishes uniformly, making it ideal for high‑volume projects demanding precise color matching and superior consistency.

This combination of precision machining, design flexibility, and scalable OEM/ODM capacity makes MDF cabinets an excellent choice for large residential, commercial, and hospitality developments.

Learn more: Ideal Custom Cabinets

3.4 Large Sheets for Scalable Production

Insight: Floor-to-ceiling cabinetry projects report a 25% reduction in assembly time using oversized MDF panels.

MDF is available in standard and oversized sheets, which is advantageous for factory-level mass production. The uniformity of MDF ensures consistent quality across large orders, making it ideal for projects where scalability is a key requirement.

3.5 Sustainable Sourcing

Insight: Green‑certified developments see up to a 10% premium on sales prices when showcasing eco‑friendly materials like certified MDF cabinetry.

More North American retailers are requesting FSC-certified MDF from overseas suppliers to align with ESG mandates. Offering certified MDF can open new channels

Often made from recycled wood fibers, MDF supports green building goals. When paired with certifications like FSC, CARB, or E1, MDF cabinets contribute to sustainability, aligning with the current emphasis on eco-friendly practices in cabinet market trends.

4. 4 Limitations of MDF Cabinets to Be Aware Of

While MDF cabinets offer many benefits, there are some limitations to consider:

4.1 Moisture Vulnerability

Standard MDF is prone to absorbing moisture, which can lead to swelling and warping. In high-humidity environments, it is best to use moisture-resistant or E1-grade MDF cabinets for kitchens and bathrooms.

Specialized Solution: Specify moisture‑resistant or E1‑grade MDF, apply continuous edge banding and high‑performance sealants, and design for proper ventilation in kitchens and baths.

Learn more: Waterproof outdoor kitchen cabinets

4.2 Lower Fastener Strength

MDF’s lower density can cause screws to strip out at high‑stress points like hinge mounts and drawer‑runner brackets.

Specialized Solution: To reinforce hinges, install steel mounting plates or hardwood backer blocks behind the hinge cups and use threaded brass inserts for a secure hold. For drawer runners, opt for confirmat screws and add metal slide‑support blocks or corner brackets to distribute load and prevent pull‑out. These targeted reinforcements ensure durable, long‑last-ing MDF cabinet assemblies.

4.3 Heavy Weight

MDF cabinets can be heavier than plywood of the same thickness, which may affect shipping costs and ease of handling on-site.

Specialized Solution: Break large runs into modular kits for easier transport, employ onsite lifting aids, or consider a plywood/MDF hybrid core where weight is critical.

4.4 Limited Use in High-Humidity or Exterior Projects

Due to moisture absorption, MDF cabinets are not recommended for outdoor applications or in areas with high humidity unless proper sealing is applied.

Specialized Solution: Restrict MDF to interior applications, or use specially coated panels with waterproof laminates or marine‑grade finishes when limited exterior use is unavoidable.

5. Is MDF Good for Cabinets? A Side-by-Side Analysis

When choosing the right material for cabinetry, it's important to weigh the benefits and drawbacks of each option. Below is a detailed comparison of MDF versus plywood and solid wood, providing insights into their strengths and limitations in key performance categories.

Detailed Comparison

Price per Linear Foot:

Engineered wood (MDF) is generally the most cost-effective option, priced between $100–$180 per linear foot. In contrast, plywood ranges from $140–$220, while solid wood is significantly more expensive at $250–$400 per linear foot. This affordability makes MDF a popular choice for projects where budget constraints are a priority.

Paint Finish Quality:

Due to its smooth, uniform surface, MDF is known for delivering excellent paint finish quality. Its lack of natural grain allows for an even coating, which is particularly beneficial for modern, painted interiors. Plywood and solid wood typically offer good finishes as well, but natural wood grain in solid wood can sometimes require additional treatment to achieve a similar level of uniformity.

Customization Options:

MDF is highly versatile and can be easily routed, cut, and shaped into intricate profiles, offering extensive customization options. This high level of design flexibility makes it ideal for bespoke projects. While solid wood also allows for customization, its natural grain may limit design consistency, and plywood generally provides moderate customization due to its layered structure.

Moisture Resistance:

MDF’s moisture resistance is moderate; however, using E1-grade variants can improve its performance in environments with higher humidity. Plywood and solid wood offer superior moisture resistance, which is a crucial consideration for areas prone to dampness or for long-term durability in high-use spaces.

Weight:

MDF tends to be heavier than plywood of similar thickness, which can affect shipping costs and ease of installation. Solid wood is similarly heavy, though its premium quality can justify the weight in luxury applications.

Screw-Holding Strength:

In terms of fastener strength, MDF generally exhibits moderate screw-holding capacity. Plywood and solid wood perform better in this category, making them more suitable for load-bearing applications where structural integrity is paramount.

Ideal Use:

MDF is ideal for painted surfaces and budget-friendly projects where a smooth finish is desired. It is well-suited for residential kitchens, office installations, and projects where cost efficiency is critical. Plywood is often chosen for utility cabinets and applications requiring long-term durability, while solid wood is typically used in luxury or high-end spaces where natural aesthetics and robust performance are essential.

Learn more: Difference between mdf and mfc vs plywood vs hdf

Comparison Table

| Category | MDF | Plywood | Solid Wood |

| Price per Linear Foot | $100–$180 | $140–$220 | $250–$400 |

| Paint Finish Quality | Excellent (smooth, uniform) | Good | Good (natural grain may vary) |

| Customization Options | High | Moderate | High |

| Moisture Resistance | Medium (improved with E1-grade) | High | High |

| Weight | Heavy | Medium | Heavy |

| Screw-Holding Strength | Moderate | Strong | Strong |

| Ideal Use | Painted surfaces, cost-sensitive projects | Utility cabinets, long-term use | Luxury/high-end spaces |

6. Certifications & Health Standards to Watch For

6.1 Why Certifications Matter

Certifications are essential for ensuring that engineered wood products used in cabinetry are free from harmful chemicals, such as excessive formaldehyde, and comply with strict safety standards. They guarantee that products not only meet North American regulatory requirements but also contribute to a healthier indoor environment. This quality assurance builds consumer trust and provides a competitive edge in an industry increasingly focused on sustainability and eco-friendly practices.

6.2 Key Certifications

Key certifications serve as vital indicators of quality, safety, and sustainability in cabinet manufacturing. By choosing certified products, contractors and brands can confidently file the necessary documentation to meet building codes, safety regulations, and green‐building standards—thereby enhancing the commercial value and marketability of their projects.

- CARB (California Air Resources Board):

This certification imposes strict limits on formaldehyde emissions from wood products. By ensuring low VOC levels, CARB certification is crucial for protecting indoor air quality and meeting the safety standards required in North American markets. For manufacturers, adherence to CARB standards is a key element in maintaining high product quality and aligning with the growing demand for environmentally responsible cabinetry.

- FSC (Forest Stewardship Council):

The FSC certification confirms that wood fibers are sourced from responsibly managed forests. It promotes eco-friendly practices by ensuring that the raw materials used in cabinet production are harvested sustainably. FSC-certified products are highly valued in the market, as they appeal to eco-conscious consumers and contribute to long-term environmental stewardship. This commitment to responsible sourcing is a major driver in cabinet market trends, especially among premium and custom cabinet brands.

- E1 Standard:

The European E1 classification sets the benchmark for low formaldehyde emissions in wood-based products. MDF panels that achieve the E1 standard have undergone rigorous testing to guarantee minimal emissions, ensuring they are safe for use in indoor environments. This certification is essential for manufacturers looking to meet international environmental standards, thereby reinforcing the sustainability credentials of their products in global cabinet market trends.

6.3 How These Certifications Impact Product Quality

Products meeting these certifications are rigorously tested to ensure enhanced material integrity and consistent manufacturing quality. Such adherence to standards guarantees that cabinetry is safe, durable, and environmentally responsible. Transparency through detailed documentation further reassures contractors and brands that the products conform to international best practices, aligning with modern market trends for quality and sustainability.

6.4 How Casta Meets These Standards

Casta Cabinetry maintains strict compliance by using panels that are fully CARB, E1, and FSC certified. Every production batch is accompanied by comprehensive documentation to verify adherence to these standards. This commitment not only ensures high performance and durability but also reinforces consumer confidence by meeting the best practices demanded by today's market.

Learn more: Casta’s ISO-Qualified Cabinet Certification: Setting the Gold Standard for Quality and Reliability

7. When to Use MDF Cabinets in Your Projects

Engineered wood cabinetry, known for its smooth, uniform finish and versatility, is a popular choice in modern interior design. However, its suitability depends on the specific environmental conditions and design requirements of a project. Below, we explore the ideal applications and limitations of using this material in cabinetry.

7.1 Ideal Project Types

Engineered wood cabinets are particularly well-suited for projects that demand cost efficiency, design flexibility, and consistent quality:

- Multi-Unit Residential Developments:

In apartment complexes and large housing projects, these cabinets offer a cost-effective solution due to their uniform quality and ease of mass production. Their smooth surface and consistent finish allow for streamlined installations across multiple units, ensuring a cohesive look and lowering overall production costs.

- Large Commercial Builds:

For commercial interiors such as offices, hotels, and retail spaces, engineered wood cabinetry provides a balance of affordability and performance. Their versatility makes them ideal for spaces that require a modern, clean aesthetic while maintaining functionality and durability. Contractors appreciate that these cabinets offer reliable quality, which helps reduce installation time and subsequent maintenance.

- Hospitality and Office Interiors:

In high-end hospitality and corporate settings, the ability to achieve a sleek, painted finish makes engineered wood an attractive option. Its smooth surface allows for a wide range of color options and design treatments, enabling designers to create tailored, contemporary looks that resonate with upscale clientele.

- DIY and Custom Projects:

Homeowners and custom designers often favor engineered wood due to its ease of customization. Its uniformity and workability mean that intricate designs, custom profiles, and unique finishes can be achieved without the inconsistencies that natural wood grain might introduce. This makes it a practical choice for bespoke projects on a budget.

Learn more: Top rated cabinet manufacturers

7.2 Not Ideal For

Despite its many benefits, engineered wood cabinetry may not be suitable for every application:

- Exterior Applications:

Standard engineered wood products are not recommended for outdoor kitchens or other exterior installations. Exposure to moisture and varying weather conditions can cause these materials to absorb water and eventually swell or warp. Special treatments are required for outdoor use, making them less ideal for such environments.

- High-Humidity Environments:

In spaces with persistently high humidity, such as certain basements or tropical climates, conventional engineered wood may deteriorate over time if not specifically engineered for moisture resistance. For these situations, it is essential to use moisture-resistant variants to maintain the integrity and durability of the cabinetry.

Engineered wood cabinetry—especially MDF cabinets—is prized for its smooth, uniform finish and design flexibility. However, its suitability varies by environment and project type. Below is a summary table of ideal and less-suitable applications for MDF cabinets:

| Application | Suitability | Reasons |

| Multi-Unit Residential Developments | Ideal | Cost‑effective mass production, consistent finish across all units, streamlined installation |

| Large Commercial Builds | Ideal | Balances affordability and performance, modern aesthetic, durable for offices, hotels, and retail spaces |

| Hospitality & Office Interiors | Ideal | Smooth surface accepts paint/finishes well, enables high‑end custom looks, low maintenance |

| DIY & Custom Projects | Ideal | Highly customizable, uniform grain-free surface for intricate profiles and unique finishes |

| Exterior Applications | Not Recommended | Standard MDF absorbs moisture, leading to swelling/warping without special sealants |

| High-Humidity Environments | Not Recommended (unless moisture‑resistant) | Conventional MDF can deteriorate in high humidity; requires moisture‑resistant variants for durability |

8. Why Casta Cabinetry Is a Reliable MDF Cabinet Partner

Casta Cabinetry stands out as a trusted partner in the custom cabinet industry, particularly for MDF cabinets. Today, 90 percent of their export clients are in the U.S., and their portfolio includes over 500 completed projects, more than 150,000 furnished apartments, and partnerships with top brands like Teka, Küppersbusch, and Cata. Here’s what makes Casta a standout partner for MDF kitchen cabinets:

8.1 Modern, High-Precision Manufacturing

- Automated Production: Over 90 percent of Casta’s 100,000 m² Long Khánh facility is automated, delivering tight tolerances (as low as 0.1 percent) and minimal waste.

- European Machinery: €6 million invested in SCM equipment, plus CNC routers, edge banders, and presses from HOMAG and Biesse guarantee consistent, precision‑cut MDF panels.

- Digital Integration: A $1 million SAP S4HANA ERP system provides end‑to‑end process control, real‑time monitoring, and rapid response to any production deviations.

8.2 Customization Expertise

- OEM & ODM Services: Tailored MDF cabinet solutions—custom sizes, special finishes, and unique material combinations—are developed through an iterative design process aligned with current market trends.

- Brand Partnerships: Two decades of collaboration with domestic leaders like Vinhomes, Masterise Homes, and Gamuda Land have honed Casta’s ability to meet stringent project requirements and deliver cohesive design lines for North American cabinet brands.

Learn more: Ideal Custom Cabinets

8.3 Health-Safe Materials

- Certified Core & Facings: All MDF panels are CARB Phase 2, E1, FSC, and JIS certified, ensuring minimal formaldehyde emissions and responsibly sourced wood.

- Third‑Party Audits: Regular ISO 9001 and ISO 14001 audits, along with in‑process inspections, verify that every batch meets or exceeds U.S. safety and environmental standards.

Learn more: Casta’s ISO-Qualified Cabinet Certification: Setting the Gold Standard for Quality and Reliability

8.4 Export-Ready Support

- Timely Delivery: Proven lead times of 25–40 days to the U.S. and Canada.

- Robust Logistics: Export‑ready packaging, experienced freight coordination, and tariff‑free status under key FTAs minimize delays and protect product integrity.

- Scale & Stability: With over 500 projects and 150,000 apartment units delivered, Casta has demonstrated its capacity to fulfill large, multi‑year contracts without compromising quality.

Learn more: Lead Times & Supply Chain Resilience: Navigating Potential Disruptions

9. Conclusion: Is MDF the Right Choice for Your Cabinets?

In summary, MDF cabinets offer a compelling combination of affordability, excellent finish quality, high customization potential, scalable production, and sustainable sourcing. With advantages such as lower material costs—up to 30–50% more affordable than solid wood—and a smooth surface ideal for painted finishes, MDF is a smart material choice for many interior applications.

While there are limitations, including moisture vulnerability and lower fastener strength, these challenges can be managed by selecting the right MDF type (such as E1-grade) and employing proper installation techniques. For contractors and cabinet brands looking for cost-effective, customizable solutions, MDF cabinets are a viable and attractive option—especially when paired with a reliable partner like Casta Cabinetry, which adheres to the highest quality and sustainability standards.

The evolving cabinet market trends, as evidenced by US cabinet market statistics and cabinet price trends, confirm that MDF cabinets continue to be a popular choice for the custom cabinet industry. As supply chain improvements and sustainable production practices advance, the future of MDF cabinets appears bright, making them an essential material in modern cabinetry.

10. FAQ

What is MDF and how does it differ from plywood or particle board?

Are MDF cabinets suitable for kitchens?

How long do MDF cabinets last?

Can MDF cabinets be customized?

What certifications should I look for when importing MDF cabinets?

Top Cabinet Manufacturers in Florida: A Capability-Based Buy...

Cabinet manufacturers in Florida play a critical role in one of the fastest-growing construction markets in North Americ...

01/10/2026 | David Nguyen

Top North Carolina Cabinet Manufacturers | Best NC Kitchen ...

North Carolina cabinet manufacturers have long been trusted across the U.S. thanks to the state’s deep heritage in woodw...

01/08/2026 | David Nguyen

Top Cabinet Manufacturers in Arizona | Best Arizona Kitchen ...

Cabinet manufacturers in Arizona have gained increasing attention as construction activity accelerates across Phoenix, T...

01/06/2026 | David Nguyen

Top Cabinet Manufacturers Indiana | Best Indiana Kitchen Cab...

Cabinet manufacturers Indiana have become increasingly relevant as contractors and developers look for dependable Midwes...

01/04/2026 | David Nguyen

Contact us

Casta is always ready to listen and answer all customers' questions