In today’s competitive cabinetry market, contractors and cabinet/furniture brands need solutions that blend affordability with high‑end performance. Particle board cabinets are prized for their cost savings—but are they any good? This guide covers how they’re made, their key types and applications, and a side‑by‑side comparison with plywood. You’ll learn their pros and cons, see data‑driven insights, and discover why they’re a smart choice for large residential and commercial projects seeking a premium look at a lower price.

Table of Contents

1. What Are Particle Board Cabinets? Understanding the Basics

Particle board cabinets are engineered wood products created by compressing wood chips, sawdust, and resin into panels. These panels are then finished with melamine, laminate, or veneer to provide a protective and attractive surface. In essence, a particle board cabinet offers a cost-effective alternative to traditional solid wood, making it popular among contractors managing budget-conscious projects.

1.1 How Particle Board Is Made

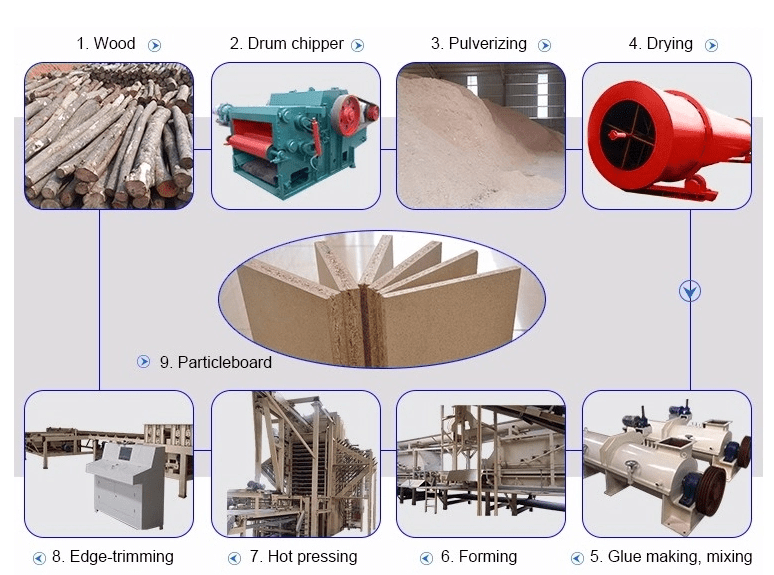

- Manufacturing Process:

- Wood chips, sawdust, and resin are compressed under high pressure to form dense panels.

- The typical density ranges from 650–700 kg/m³.

- Panels are finished with melamine, laminate, or veneer to enhance appearance and durability.

- Key Advantages:

- Uniform texture with no grain, making it easy to finish.

- Economical production method that reduces material waste and overall costs.

1.2 Where It’s Used in Cabinetry

- Applications:

- Commonly used in cabinet carcasses, drawer boxes, and shelving units.

- Widely adopted in budget cabinet lines and is a popular choice in flat-pack and Ready-to-Assemble (RTA) furniture.

- Benefits:

- Its low weight and low cost make it ideal for projects where transportation and installation efficiency are key.

1.3 Types of Particle Board Cabinets

| Type | Characteristics | Applications |

| Raw Particle Board | Unfinished, basic form; lowest cost; primarily used as a structural core. | Internal structures (cabinet carcasses, back panels, drawer boxes). |

| Melamine-Faced Particle Board | Coated with melamine film; scratch and moisture resistant; decent aesthetic finish. | Visible surfaces in budget cabinetry, office furniture, dormitory cabinetry. |

| Veneered Particle Board | Features a high-quality wood veneer; improved aesthetics and texture; higher perceived value. | Mid-range cabinetry, custom furniture where appearance is key (e.g., kitchen cabinets, display units). |

1.4 Who Should Use Particle Board Cabinets?

- Contractors:

- Ideal for large-scale projects where cost-efficiency is crucial.

- Suitable for flat-pack or RTA applications, reducing shipping and installation costs.

Learn more: RTA furniture manufacturers

- Cabinet and Furniture Brands:

- Perfect for budget or mid-range product lines, offering a balance between affordability and aesthetics.

- Can be integrated with high-end finishes on visible surfaces to boost appearance.

- Companies and Developers:

- Beneficial for mass-produced cabinetry in commercial projects where low cost and ease of assembly are key priorities.

2. 5 Advantages of Particle Board Cabinets for Contractors & Brands

Particle board cabinets offer a range of advantages that make them a popular choice for both residential and commercial applications. Here are five major benefits:

2.1 Cost-Effective for Large Projects

- Advantage & Measurable Savings:

- Particle board cabinets cost 30–60% less than plywood or MDF—translating to savings of $20,000–$50,000 on a 200‑unit apartment build.

- Practical Applications:

- Ideal for multifamily housing, student dormitories, worker accommodations, affordable senior living, and pop‑up retail fixtures.

- Aesthetic Note:

- Despite the lower cost, a wide range of finishes—paint, thermofoil, or veneer—delivers the natural wood look and high‑end feel clients expect.

2.2 Uniform & Flat Surface

- Advantage:

- The manufacturing process produces a consistent, flat surface ideal for laminating and edge banding.

- Impact:

- Results in a smooth, uniform appearance that enhances the overall aesthetics of particle board cabinets.

- Aesthetic Note:

- The flawless surface provides a modern, sophisticated look that appeals to both residential and commercial customers.

2.3 Lightweight and Easy to Handle

- Advantage:

- Particle board cabinets are significantly lighter than plywood or solid wood, making them easier to transport, install, and ship.

- Impact:

- Lower shipping costs and faster on-site assembly, which is particularly beneficial for RTA (Ready-to-Assemble) and modular cabinet systems.

- Industry Relevance:

- The lightweight nature of these cabinets enhances scalability and distribution efficiency, reducing overall project timelines.

2.4 Compatible with Modern Machinery

- Advantage:

- Works exceptionally well with CNC cutting, drilling, and automated assembly.

- Impact:

- Enables precise and efficient production, ensuring that every particle board cabinet meets stringent quality standards.

- Aesthetic Note:

- Advanced machining ensures clean edges and a high-quality finish, contributing to a premium look.

2.5 Sustainable Sourcing

- Advantage:

- Made from recycled wood fibers and by‑products, particle board cabinets close the loop on timber use and support circular manufacturing practices.

- Impact:

- Their eco-friendly nature is enhanced by using FSC- or CARB-compliant resins,with a recycled core that not only appeals to eco‑minded clients but also reduces pressure on old‑growth forests—helping curb deforestation.

- Aesthetic Note:

- These greener credentials enhance brand value and convey a responsible image, all while delivering the same clean, high‑quality finish that designers and customers expect.

3. 4 Disadvantages of Particle Board Cabinets (and How to Manage Them)

Despite their many advantages, particle board cabinets come with certain limitations. Here’s how to address these challenges effectively:

3.1 Low Moisture Resistance

- Disadvantage:

- Particle board swells when exposed to water, reducing durability and lifespan.

- Enhanced Solutions:

- Specify laminated or moisture‑resistant formulations (e.g., V313) for wet zones like under‑sink vanities and shower niches.

- During manufacturing, apply a full‑coverage moisture barrier sealant or high‑performance laminate on all exposed edges and surfaces.

- On‑site, ensure proper caulking at joints and maintain good ventilation to prevent humidity buildup.

- Impact on Appearance:

- Use It: Install V313 particle board cabinets for kitchen islands, built‑in wardrobes, and bathroom vanities away from direct water spray—projects in condos, hotels, and office break rooms have shown zero edge swelling over five years with these treatments.

- Avoid It: Do not use standard particle board behind sinks, inside wet bars, or in outdoor kitchens unless fully encapsulated and protected by waterproof panels or tile surrounds.

Learn more: Moisture-resistant kitchen cabinets

3.2 Weaker Screw-Holding Strength

- Disadvantage:

- Over time, threads in particle board may loosen, compromising structural integrity.

- Enhanced Solutions:

- Use confirmat screws or dowel joints to enhance durability.

- Incorporate metal inserts to significantly boost screw-holding strength and overall stability.

- Reinforce critical load-bearing points with additional hardware.

- Impact on Appearance:

- Improved fastening not only extends the cabinet's lifespan but also ensures that the clean, refined look of particle board cabinets remains intact.

3.3 Shorter Lifespan in High-Use Areas

- Disadvantage:

- Particle board cabinets may have a lifespan of 5–10 years in high-traffic or heavy-load environments.

- Enhanced Solutions:

- Use particle board for internal shelving or low-stress components.

- Consider hybrid construction methods, combining particle board with more durable materials at stress points.

- Impact on Appearance:

- Proper application and maintenance can preserve the attractive, uniform appearance of particle board cabinets over their expected lifespan.

3.4 Lower Perceived Value

- Disadvantage:

- Often perceived as “cheap” by luxury clients, which can affect market positioning.

- Enhanced Solutions:

- Elevate appearance by combining particle board with high-end finishes or premium veneers.

- Pair particle board with plywood on visible surfaces to boost perceived quality.

- Utilize custom finishes and decorative hardware to enhance overall aesthetics.

- Impact on Appearance:

- With advanced finishing techniques, particle board cabinets can achieve a high-end look that rivals more expensive materials.

- When to Use:

- Ideal for mid‑range residential builds, student housing, offices, and retail fixtures where budget and aesthetics must align.

- When Not to Use:

- Avoid in luxury custom homes, high‑end showrooms, or executive suites where a premium solid‑wood image is essential.

Learn more: What materials of furniture are renewable and sustainable

4. Particle Board vs. Plywood Cabinets: A Data-Driven Comparison

Understanding the differences between particle board cabinets and plywood is critical for making informed decisions. The table below provides a side-by-side analysis of key features:

| Feature | Particle Board Cabinets | Plywood Cabinets |

| Cost per Sheet (4’x8’) | $15–$25 | $30–$50 |

| Weight | Light – reduces shipping and handling costs | Medium – provides extra structural stability |

| Screw-Holding Strength | Moderate – improved with metal inserts or reinforcement | High – ideal for load-bearing applications |

| Moisture Resistance | Low (unless treated with moisture-resistant coatings) | High – suitable for high-moisture environments |

| Surface Smoothness | Excellent – uniform and ideal for laminating and finishing | Moderate – may exhibit natural wood grain variations |

| Lifespan | 5–10 years in heavy-use environments | 15–25 years with proper maintenance |

| Processing Time | Faster – due to simplified layering and uniform structure | Slightly longer – complex layering requires additional finishing work |

| Installation Stability | Adequate for partitions and non-load-bearing applications | Superior for structural, load-bearing uses |

| Maintenance Costs | Lower initial cost; may require periodic refinishing in humid conditions | Higher upkeep; offers long-term durability with proper care |

- Best Use Cases:

- Particle Board Cabinets: Best for budget-sensitive projects, RTA systems, and installations where a sleek, uniform appearance is critical.

- Plywood Cabinets: Preferred for high-end residential and commercial applications that demand greater durability and longevity.

- Target Audience:

- Particle Board Cabinets: Ideal for mid-range residential, multi-family, and commercial spaces that prioritize aesthetics and cost efficiency.

- Plywood Cabinets: Suited for luxury homes and heavy-use commercial settings requiring robust construction.

Learn more: Sourcing Cabinets and Furniture from Vietnam: Your Ultimate Guide

5. When Are Particle Board Cabinets a Smart Choice?

When deciding on materials for cabinetry projects, it's essential to match the product to the project's specific needs. Here are detailed considerations for when to opt for this cost-effective material, and when it might be better to look for alternatives:

5.1 Ideal Applications

Particle board cabinets offer a strong ROI through lower material and installation costs, making them ideal for:

- Budget-Conscious Projects:

- Usage: Highly suitable for projects such as hostels, student housing, and worker accommodations where tight budgets are a primary concern. Upfront costs 40–60% below plywood, delivering payback within the first project.

- Benefits: The affordability of these cabinets allows developers to maximize returns on large-scale projects without compromising overall functionality.

- Low-Traffic Areas:

- Usage: Best applied in settings like closets, utility rooms, or laundry areas, where the demands on the cabinetry are minimal. Minimal upkeep yields a 10–15% annual ROI versus high‑end materials.

- Benefits: In these environments, the structural load is low, meaning that the less robust nature of the material is less likely to be a drawback, while still providing a clean, uniform finish.

- RTA/Flat-Pack Systems:

- Usage: Ideal for Ready-to-Assemble systems offered through retailers or online platforms. Lighter weight cuts shipping and labor expenses by up to 25%, quickly recouping investment.

- Benefits: Their light weight makes them easier to ship and assemble on-site, reducing logistical complexity and overall project costs.

Learn more: Top 10 RTA cabinet supplier and manufacturers

- Display and Light-Duty Installations:

- Usage: Effective in installations where visual appeal is important but the physical stress on the material is minimal, such as in office partitions or decorative storage solutions.

- Benefits: These applications take advantage of the smooth, uniform finish and the ability to be customized with various surface treatments, ensuring a polished appearance without the need for heavy-duty construction.

5.2 When to Avoid

In high‑moisture or luxury residential projects, replacement and client expectations can negate savings and delay ROI.

- High-Moisture Environments:

- Concerns: Areas with persistent humidity, such as certain kitchens or bathrooms, can cause the material to swell or deteriorate unless specifically treated.

- Recommendation: In these cases, either avoid using this material or opt for moisture-resistant versions that have been enhanced to withstand damp conditions.

- High-End Residential Projects:

- Concerns: For luxury installations where long-term durability and the authentic look of solid wood are critical, this material might not meet the high expectations of discerning clients.

- Recommendation: In upscale projects, it may be preferable to use higher-grade materials that offer superior durability and a more refined appearance, ensuring that the investment stands the test of time.

6. Certifications Matter: What to Look For

Certifications are essential for ensuring that cabinets meet strict safety, quality, and sustainability standards. For contractors and brands, these certifications not only safeguard consumer health but also enhance your product's market appeal. Here's a detailed look at the key certifications and why they matter:

- CARB Phase 2 Certification

- Value:

- Limits formaldehyde emissions from wood products, which is critical for maintaining a healthy indoor environment.

- Importance:

- Ensures compliance with US environmental regulations, reducing the risk of health hazards associated with indoor air pollution.

- Enhances consumer trust by confirming that the materials used adhere to strict emission standards.

- For Contractors: Simplifies specification in high‑end residential and commercial builds requiring low‑emission materials.

- For Brands: Facilitates smoother export to EU and other markets with stringent VOC limits.

- Value:

- E1 Standard

- Value:

- Indicates that the adhesives and resins used in manufacturing emit low levels of volatile organic compounds (VOCs).

- Importance:

- Critical for global trade as it ensures that products meet international safety benchmarks.

- Assures buyers that the material is safe for indoor use, supporting a clean and healthy living or working environment.

- For Contractors: Contributes points toward LEED and other green‑building certifications, enhancing project credentials.

- For Brands: Leverages consumer demand for sustainable products, boosting brand reputation and market differentiation.

- Value:

- FSC (Forest Stewardship Council) Certification

- Value:

- Guarantees that the wood used in production is sourced from responsibly managed forests.

- Importance:

- Supports sustainable practices and environmentally friendly manufacturing.

- Enhances brand reputation by aligning with the increasing consumer demand for sustainable and eco-friendly products.

- For Contractors: Minimizes on‑site adjustments and warranty claims, keeping projects on time and within budget.

- For Brands: Guarantees reliable product performance, strengthening trust with distributors and end users.

- Value:

- Casta’s Commitment to Quality

- Every shipment comes with full certification documentation, demonstrating adherence to CARB, E1, and FSC standards.

- This rigorous certification process provides contractors and brands with the confidence that the product quality is consistently high and meets all necessary safety regulations.

- By maintaining these certifications, Casta ensures that its products not only deliver superior performance but also contribute to a healthier and more sustainable built environment.

Learn more: Cabinet certification

7. Why Choose Casta Cabinetry for Particle Board Cabinets

Casta Cabinetry is a trusted partner for contractors and cabinet brands seeking high-quality particle board cabinets that combine modern aesthetics with cost-effective performance. Here’s why Casta is the supplier of choice:

7.1 Vietnam-Based Production with European Precision

- Advanced Manufacturing:

- Casta’s production facility spans over 100,000 m² in Vietnam with more than 90% automation.

- Equipped with state-of-the-art European machinery (HOMAG, Biesse, SCM) for precise cutting, drilling, and finishing—bolstered by a €6 million investment in CNC systems and a $1 million SAP S4HANA ERP implementation to ensure seamless, high‑speed production..

- Impact on Appearance:

- The high-tech production process ensures that every particle board cabinet has a consistent, high-quality finish that meets modern design standards.

7.2 Flexible Customization for B2B Orders

- Tailored Solutions:

- Offers custom sizes, panel configurations, and finishes tailored for North American preferences.

Learn more: Ideal Custom Cabinets

- Supports OEM/ODM services to create unique, private-label collections that reflect your brand’s identity.

- Enhancing Visual Appeal:

- Customization options allow for a variety of finishes that enhance the natural, upscale appearance of particle board cabinets.

7.3 Certified, Health-Safe Materials

- Quality Assurance:

- All products are manufactured with CARB, FSC, and E1 certified particle board, ensuring a safe and sustainable product.

- Full documentation accompanies every shipment, providing peace of mind regarding product quality and longevity.

- Visual Appeal:

- Certified materials contribute to a refined, consistent appearance that enhances overall market appeal.

Learn more: Casta’s ISO-Qualified Cabinet Certification: Setting the Gold Standard for Quality and Reliability

7.4 Export-Ready Logistics & Support

- Efficient Delivery:

- Lead time of 25–40 days to North America, ensuring timely project completion.

- Robust export-ready packaging minimizes damage and simplifies customs clearance.

- Logistics Impact:

- Streamlined logistics and reduced shipping costs help maintain the attractive finish and integrity of every particle board cabinet.

Learn more: Casta’s Outstanding International Projects

8. Conclusion: Are Particle Board Cabinets Good for You?

In conclusion, particle board cabinets offer a compelling mix of cost-effectiveness, modern appearance, and ease of production, making them an excellent choice for both residential and commercial projects. They provide a smooth, uniform finish and are especially well-suited for applications where budget constraints are a priority, such as in RTA systems and flat-pack cabinetry.

Despite some limitations—such as lower moisture resistance and a shorter lifespan compared to plywood—these challenges can be mitigated through proper treatment and quality manufacturing processes. With the right finishes and maintenance, particle board cabinets deliver a premium look that can rival more expensive materials.

For contractors, cabinet/furniture brands, and companies in North America looking for scalable, high-quality solutions, particle board cabinets present a smart, sustainable, and cost-effective option. By partnering with trusted suppliers like Casta Cabinetry, you can ensure that your cabinetry projects not only meet market demands but also stand out in terms of both performance and aesthetic appeal.

9. FAQ Section

What is a particle board cabinet made of?

Are particle board cabinets any good for kitchens?

How does a particle board cabinet compare to plywood?

Can particle board cabinets be customized?

What certifications should I look for when purchasing particle board cabinets?

How long do particle board cabinets typically last?

What are the main advantages of particle board cabinets?

Why are particle board cabinets a good option for RTA systems?

Top Cabinet Manufacturers in Florida: A Capability-Based Buy...

Cabinet manufacturers in Florida play a critical role in one of the fastest-growing construction markets in North Americ...

01/10/2026 | David Nguyen

Top North Carolina Cabinet Manufacturers | Best NC Kitchen ...

North Carolina cabinet manufacturers have long been trusted across the U.S. thanks to the state’s deep heritage in woodw...

01/08/2026 | David Nguyen

Top Cabinet Manufacturers in Arizona | Best Arizona Kitchen ...

Cabinet manufacturers in Arizona have gained increasing attention as construction activity accelerates across Phoenix, T...

01/06/2026 | David Nguyen

Top Cabinet Manufacturers Indiana | Best Indiana Kitchen Cab...

Cabinet manufacturers Indiana have become increasingly relevant as contractors and developers look for dependable Midwes...

01/04/2026 | David Nguyen

Contact us

Casta is always ready to listen and answer all customers' questions