In today’s competitive cabinetry market, contractors and cabinet brands are seeking cost-effective solutions that don’t compromise on style. Veneered particle board cabinets have emerged as a smart choice, offering the refined look of natural wood through high-quality veneers while keeping costs low. These cabinets are popular in both residential and commercial projects for their upscale appearance and budget-friendly pricing.

This guide covers everything you need to know about veneered particle board cabinets—from their composition and veneer finishes to their practical applications and key advantages versus alternative materials like plywood. Learn how these cabinets, with their natural allure as kitchen cabinet veneers and other veneers for cabinets, can deliver both performance and visual appeal. For contractors and brands aiming to optimize costs while maintaining a premium look, veneered particle board cabinets offer a compelling solution.

Table of Contents

1. What Are Veneered Particle Board Cabinets? A Material Overview

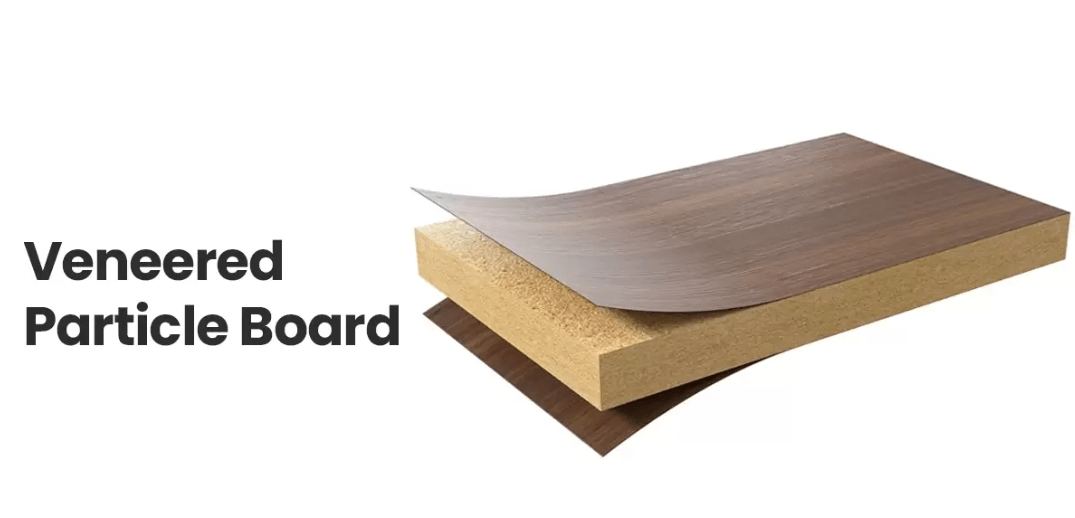

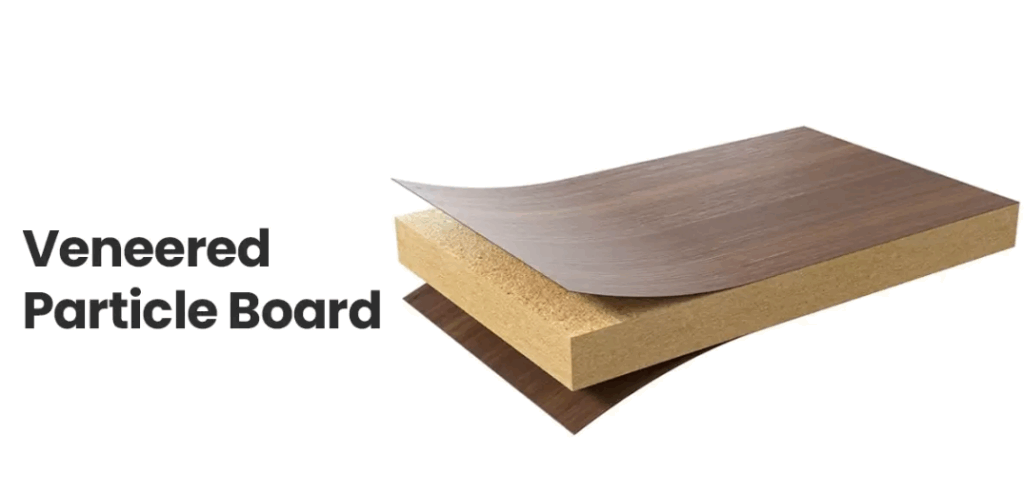

Veneered particle board cabinets are engineered wood products that combine the affordability and workability of particle board with the aesthetic appeal of natural wood veneers. These cabinets are created by pressing wood particles with resin into a dense panel and then applying a thin layer of natural wood veneer—such as oak, ash, walnut, or teak—over the surface. The result is a cabinet that mimics the look of solid wood while offering significant cost savings.

1.1 Definition & Structure

- Core Material:

- Made from wood chips, sawdust, and resin pressed under high heat and pressure.

- Typical density ranges from 650 to 700 kg/m³.

- Surface Layer:

- Finished with a natural wood veneer, providing an attractive and upscale look.

- Bonding Process:

- Uses high-pressure adhesives and precise heat control to ensure strong and durable bonding.

This process results in veneered particle board cabinets that have a uniform, smooth surface, ideal for achieving a premium appearance without the premium cost.

1.2 Veneer Finishes for Cabinets

The appeal of veneered particle board cabinets lies in their ability to offer a luxurious, natural wood look at a fraction of the cost. Here are some popular veneer options and their aesthetic impacts:

- Natural Wood Veneer (0.6 – 2 mm thick):

- Each piece showcases unique wood grain patterns.

- Oak: 0.8 – 1.2 mm for durability. Offers a classic, timeless look that works well in traditional and transitional designs.

- Maple: 0.6 – 1 mm. Delivers a bright, clean appearance ideal for modern, minimalist styles.

- Birch: 0.7 – 1 mm. Provides a smooth, subtle grain that is perfect for contemporary settings.

- Walnut: 1.2 – 2 mm. Conveys a rich, luxurious feel suitable for upscale interiors.

- Teak: 1 – 1.5 mm. Adds a warm, exotic touch, often used in coastal or high-end designs.

- Finishing Options:

- Stained: Enhances the natural grain while adding warmth and depth.

- Clear-Coated: Preserves the natural color and texture for a refined look.

- UV Lacquered: Provides a high-gloss, durable finish for a sleek, modern appearance.

Learn more: Wood finish kitchen cabinets

These finishes not only enhance the natural beauty of the veneers for cabinets but also help protect the surface, ensuring that kitchen cabinet veneers maintain their aesthetic appeal over time.

1.3 Applications in Cabinetry

Veneered particle board cabinets are versatile and find extensive use in modern interior design:

- Kitchen Cabinets:

- Widely used for cabinet fronts, providing a premium look without the high cost of solid wood.

- Wardrobes and Storage Units:

- Ideal for residential and commercial storage solutions.

- Office and Retail Installations:

- Employed in wall panels and shelving units where a uniform, upscale appearance is desired.

Due to their lightweight and cost-effective nature, these cabinets are also popular in Ready-to-Assemble (RTA) and flat-pack systems.

1.4 Who Should Use Veneered Particle Board Cabinets?

- Contractors:

- Ideal for large-scale projects such as multi-family housing, student accommodations, and commercial installations.

- Their cost-efficiency and ease of assembly make them a smart choice for contractors managing extensive builds.

- Cabinet and Furniture Brands:

- Perfect for mid-range product lines where budget constraints exist but a premium look is essential.

- Suitable for custom projects that require a high-end appearance combined with consistent quality.

- Developers and Companies:

- Beneficial for mass-produced cabinetry in commercial projects, where efficient production and attractive aesthetics are critical.

Learn more: Sourcing Cabinets and Furniture from Vietnam: Your Ultimate Guide

2. 6 Key Advantages of Veneered Particle Board Cabinets

Veneered particle board cabinets are celebrated for their exceptional blend of cost-efficiency, aesthetics, and functionality. Here are six key advantages that explain why this material is rapidly gaining traction among contractors and cabinet brands.

2.1 Cost-Effective with a Premium Look

- Cost Advantage:

- Up to 30–50% cheaper than solid wood cabinets, making veneered particle board an economical choice.

- High-End Aesthetics:

- Delivers the appearance of natural wood with refined grain patterns, offering a luxurious look without the high cost.

- Market Impact:

- Ideal for projects where budget constraints are critical but a high-end finish is still desired, ensuring that the overall appearance of the cabinets meets modern design standards.

2.2 Lightweight Yet Stable

- Advantage:

- Being lighter than plywood or solid wood, these cabinets are easier to transport, install, and handle.

- Industry Relevance:

- This lightweight nature is particularly beneficial for RTA (Ready-to-Assemble) systems and modular cabinetry, reducing shipping costs and simplifying on-site assembly.

- Overall Benefit:

- Enhances project efficiency and reduces labor costs, making them attractive for large-scale projects.

2.3 Environmentally Friendly

- Sustainable Sourcing:

- Manufactured from wood waste, contributing to circular manufacturing practices.

- Eco-Friendly Certification:

- Often produced using FSC- or CARB-compliant resins, supporting environmental sustainability.

- Brand Image:

- Appeals to eco-conscious consumers and enhances the reputation of brands committed to green practices.

2.4 Good Dimensional Stability

- Advantage:

- Engineered for uniform thickness and density, particle board cabinets resist warping far better than solid wood under changing conditions.

- Impact:

- In multi‑unit residential corridors or high‑traffic office pantries—where temperature and humidity can fluctuate daily—these cabinets maintain perfectly aligned doors and seamless panel fits. For example, a student housing project in a coastal city reported zero door misalignment over two years, despite seasonal humidity swings. This reliability minimizes onsite adjustments and keeps maintenance costs low.

2.5 Customizable for Design Consistency

- Design Flexibility:

- The uniform surface of veneered particle board allows for precise CNC machining, edge banding, and customization.

- OEM Potential:

- Ideal for creating brand-specific cabinetry solutions with customized finishes that mimic natural wood.

- Aesthetic Appeal:

- Supports a range of finishes that enhance the natural beauty of the veneer, ensuring consistent color and grain patterns across large orders.

2.6 Easier to Work With

- Manufacturing Efficiency:

- Works well with modern automated production systems, enabling high-speed processing.

- Installation Ease:

- Its smooth surface and lightweight structure facilitate quicker assembly and lower overall installation costs.

- Final Look:

- Results in a high-quality, uniform finish that enhances the overall visual appeal of the finished product.

3. 4 Common Drawbacks (and Practical Solutions)

While veneered particle board cabinets offer numerous benefits, it’s important to be aware of potential drawbacks and how to address them effectively.

3.1 Moisture Sensitivity

- Disadvantage:

- The particle board core is prone to swelling when exposed to moisture, which can compromise the appearance and integrity of the cabinet.

- Enhanced Solutions:

- Use laminated or moisture-resistant versions (e.g., V313) specifically designed for wet environments.

- Apply high-quality sealants or moisture barrier coatings during manufacturing.

- Ensure proper installation with adequate ventilation to minimize moisture exposure.

- Impact on Appearance:

- With proper treatment, veneered particle board cabinets can maintain their sleek and consistent finish, even in moisture-prone areas.

Learn more: Moisture-resistant kitchen cabinets

3.2 Lower Impact Resistance

- Disadvantage:

- Veneers can dent or chip under heavy impact, affecting both aesthetics and durability.

- Enhanced Solutions:

- Apply protective top coatings such as UV lacquer to reinforce the veneer surface.

- Use thicker veneer layers or hybrid designs that combine particle board with more resilient materials in high-traffic areas.

- Impact on Appearance:

- These solutions help maintain the refined look of kitchen cabinet veneers, ensuring a lasting, premium finish.

3.3 Requires Skilled Manufacturing

- Disadvantage:

- Poor pressing or gluing can lead to veneer bubbling, peeling, or delamination, detracting from the cabinet’s overall look.

- Enhanced Solutions:

- Partner with factories that use automated veneer presses and maintain strict quality control protocols.

- Employ advanced adhesive technologies and conduct regular quality inspections.

- This ensures that every piece of veneered particle board maintains a uniform, high-end appearance.

- Impact on Appearance:

- Consistent manufacturing methods guarantee that the natural beauty of the veneers for cabinets is preserved, delivering a flawless finish every time.

3.4 Limited Grain Customization

- Disadvantage:

- Natural veneer patterns can vary, making it challenging to achieve uniformity in large orders.

- Enhanced Solutions:

- Use reconstituted veneer for projects where consistency is critical.

- This method replicates the appearance of natural wood while providing uniform color and grain, ensuring that all veneered particle board cabinets exhibit a consistent, high-quality finish.

- Impact on Appearance:

- Enhances the overall visual appeal and marketability, particularly for brands that demand a premium, consistent look in their product lines.

4. Veneered Particle Board Cabinets vs. Other Cabinet Materials: A Data-Driven Comparison

Understanding how veneered particle board cabinets stack up against other materials is essential for making informed decisions. Below is a detailed side-by-side comparison:

| Feature | Veneered Particle Board Cabinets | Solid Wood Cabinets | Plywood with Veneer | Melamine Particle Board |

| Cost per Sheet (4’x8’) | $$ ($20–$35) (depending on core density and veneer type) | $$$$ ($50+ per sheet) | $$$ ($30–$50) | $ ($15–$25) |

| Appearance | Natural wood look with customizable veneers; high-end finish possible | Authentic wood grain and texture; premium, luxurious appearance | Natural wood look with high durability; consistent, premium finish | Artificial look; less natural; suitable for budget projects |

| Durability | Medium – suitable for non-structural, decorative applications | High – best for load-bearing and long-term use | High – excellent for both aesthetics and structural applications | Medium – lower durability and impact resistance |

| Moisture Resistance | Medium – can be improved with treatments and sealants | High – inherently more moisture resistant | High – excellent for high-moisture environments | Low – generally requires additional treatment |

| Screw-Holding Strength | High – with proper reinforcement, can be comparable to plywood | Very high – natural strength of solid wood | High – well-constructed laminates offer good strength | Moderate – may require extra reinforcement for heavy applications |

| Lifespan | 5–10 years in high-use conditions; improved with proper treatments | 30+ years when well maintained | 15–25 years with proper maintenance | 5–10 years, depending on application |

| Processing & Installation | Faster processing; lighter weight reduces installation and shipping costs | Longer processing; heavier weight increases logistics complexity | Moderate processing time; balanced weight | Fast processing; lower cost, but higher maintenance costs |

| Best Use Cases | Budget-friendly, aesthetically pleasing projects; ideal for mid-range applications | Luxury and high-end custom cabinetry | Premium projects requiring a natural look and moisture control | Budget projects where appearance is less critical |

| Target Audience/Project Type | Mid-range residential, multi-family, and commercial spaces prioritizing aesthetics and cost efficiency | Luxury homeowners and high-end custom projects | Premium residential and commercial projects requiring durability and moisture resistance | Budget-conscious projects, entry-level residential, offices, and student housing |

While solid wood cabinets remain the gold standard for luxury and long‑term durability, and plywood with veneer excels in moisture‑prone or structural applications, veneered particle board cabinets offer the best balance of cost savings, high‑end appearance, and ease of installation for mid‑range residential and commercial projects. Their moderate durability and customizable finish make them a smart, practical choice when budgets and timelines are tight—provided moisture protection is addressed—making them the go‑to option for contractors and brands seeking quality without the premium price of solid wood.

Learn more: Sourcing Cabinets and Furniture from Vietnam: Your Ultimate Guide

5. When Are Veneered Particle Board Cabinets a Smart Choice?

Choosing the right cabinet material depends on the specific needs of your project. Here’s when veneered particle board cabinets are the ideal choice:

5.1 Ideal Applications

- Budget-Conscious Projects:

- Perfect for hostels, student housing, and worker accommodations where cost efficiency is essential.

- Low-Traffic Areas:

- Suitable for closets, utility rooms, or laundry cabinets where heavy load is not a concern.

- RTA/Flat-Pack Systems:

- Ideal for Ready-to-Assemble cabinetry sold through retailers or online, reducing shipping and assembly costs.

Learn more: Top 10 RTA cabinet supplier and manufacturers

- Display and Light-Duty Installations:

- Effective in applications where a high-end, natural wood look is desired, but stress on the material is minimal.

5.2 When to Avoid

- High-Moisture Environments:

- Not recommended for areas with persistent humidity unless specially treated.

- High-End Residential Projects:

- May not be suitable for luxury projects where long-term durability and a solid wood appearance are critical.

6. Kitchen Cabinet Veneers: Trends & Use Cases

The demand for natural veneers in cabinetry is on the rise, driven by modern design preferences that emphasize simplicity, warmth, and authenticity. Below is a detailed analysis of current trends and practical applications for kitchen cabinet veneers.

6.1 Natural Veneers in Modern Kitchens

- Trend Overview:

- Popular Styles:

- Minimalist, Scandinavian, and transitional designs are increasingly in demand, favoring clean lines and natural textures.

- A growing number of contractors and interior designers are opting for kitchen cabinet veneers that deliver a warm, inviting appearance.

- Consumer Preferences:

- Customers are looking for a balance between modern functionality and the timeless beauty of natural wood.

- Market surveys indicate that up to 65% of design professionals now favor natural veneers for their ability to enhance the overall aesthetic of a space.

- Popular Styles:

- Design Impact:

- Texture & Depth:

- Veneered finishes add a rich texture and visual depth to cabinetry, elevating the overall look and feel of the interior.

- The natural grain patterns in veneers create a dynamic and elegant surface that can serve as a focal point in kitchen design.

- Versatility:

- Whether stained for a classic look or clear-coated for a modern finish, veneers for cabinets provide flexible design options that can be tailored to any style preference.

- Texture & Depth:

- Market Demand:

- Growing Appeal:

- The rising trend towards natural finishes has made veneered particle board cabinets an attractive option for mid-range to upscale projects.

- Increased consumer demand for eco-friendly, aesthetically pleasing cabinetry is pushing more brands to adopt natural veneers.

- Economic Impact:

- Veneers provide an upscale appearance at a lower cost compared to solid wood, making them a cost-effective choice for large projects without sacrificing style.

- Growing Appeal:

Learn more: Kitchen cabinet trends

6.2 Where to Use Veneered Cabinets

- Ideal Installations:

- Cabinet Fronts & Panels:

- Veneered cabinets are best suited for areas where appearance is paramount, such as cabinet fronts in kitchens, bathrooms, and living areas.

- Wall-Mounted Units & Floating Shelves:

- Use veneered cabinets in wall-mounted or floating installations to create a light, open feel that adds sophistication to any room.

- Display and Showcase Areas:

- Perfect for areas where the natural beauty of the wood grain is a key design element, such as in display cabinets or accent pieces.

- Cabinet Fronts & Panels:

- Enhanced Aesthetics:

- Highlighting Natural Grain:

- The use of high-quality veneers ensures that the natural grain and texture of the wood are accentuated, adding an element of luxury.

- Customization Options:

- Veneers can be finished in various ways (stained, clear-coated, or UV lacquered) to match specific design schemes and enhance the overall look of the cabinetry.

- Consistent Look:

- For brands looking to maintain a uniform appearance across large projects, veneered cabinets offer consistent texture and color, reinforcing a high-end market presence.

- Highlighting Natural Grain:

7. Certifications & Standards for Health & Sustainability

Certifications are critical for ensuring that the materials used in veneered particle board cabinets meet rigorous safety, quality, and sustainability standards. Here’s what you need to look for:

- CARB Phase 2:

- Value: Limits formaldehyde emissions to ensure safer indoor air quality.

- Importance: Essential for compliance with US regulations, protecting both health and product integrity.

- E1 Standard:

- Value: Confirms low-emission levels from adhesives and resins, reducing VOCs.

- Importance: Ensures that materials are safe for indoor use and meet global trade requirements.

- FSC Certification:

- Value: Guarantees that wood is sourced from responsibly managed forests.

- Importance: Enhances brand reputation and meets consumer demand for sustainable products.

- Casta’s Commitment:

- Every shipment of veneered particle board cabinets comes with complete certification documentation, ensuring full compliance with CARB, E1, and FSC standards.

Learn more: Cabinet certification

8. Why Contractors & Brands Should Consider Veneered Particle Board Cabinets

Veneered particle board cabinets provide a unique combination of affordability, aesthetics, and performance. Here’s why they are an excellent choice for contractors and brands:

8.1 Ideal for Mid-Range & Volume Projects

- Advantage:

- These cabinets are cost-effective and scalable, making them ideal for projects like multi-family housing, retail chains, and hotel furnishings.

- Impact:

- Their affordability enables large-scale production without compromising on appearance, making them attractive for budget-conscious yet design-savvy projects.

- Target Audience:

- Mid-range residential, multi-family, and commercial spaces that prioritize both aesthetics and cost efficiency.

Learn more: Outstanding Projects

8.2 Consistent Quality at a Competitive Price

- Advantage:

- With prices significantly lower than premium solid wood, veneered particle board cabinets deliver a natural, upscale look while saving up to 30–50% on costs.

- Impact:

- This balance of cost and quality allows brands to meet market demands effectively, offering products that are both visually appealing and economically viable.

- Visual Appeal:

- The natural veneer finish enhances the overall look, providing an authentic wood appearance that rivals more expensive materials.

8.3 Better for Logistics & Assembly

- Advantage:

- Their lightweight nature simplifies shipping, handling, and installation.

- Impact:

- Reduced shipping costs and faster assembly times lower overall project expenses, a critical factor in RTA (Ready-to-Assemble) and modular cabinet systems.

- Logistical Efficiency:

- Simplifies on-site installation, ensuring that projects can be completed faster and more efficiently.

Learn more: Lead Times & Supply Chain Resilience: Navigating Potential Disruptions

9. Why Work with Casta Cabinetry for Veneered Cabinets

Casta Cabinetry operates two 100,000 m², 90%-automated factories in Cat Lai and Long Khánh, producing over 20,000 custom veneered cabinet sets per month.

Founded in 2002, they leverage 20+ years of industry expertise alongside a €6 million investment in CNC machining lines and a $1 million SAP S4HANA ERP system for real‑time production control and precision. Having completed 500+ projects—equipping 150,000+ apartment units and 100+ hospitality venues—and exporting 90% of their output to North America under 25–40‑day lead times and tariff‑free FTAs, Casta delivers scalable, high‑quality veneered particle board cabinets that meet contractors’ and brands’ most demanding requirements.

9.1 High-Precision Manufacturing from Vietnam

- State-of-the-Art Facility:

- Operating in a 100,000+ m² facility with over 90% automation.

- Equipped with advanced European machinery (HOMAG, Biesse, SCM) for precise cutting, pressing, and edge banding.

- Consistent Appearance:

- The high-tech production process ensures that every cabinet meets rigorous quality standards, delivering a flawless, high-end appearance.

9.2 Fully Customizable Solutions

- OEM & ODM Services:

- Offers tailored options for sizes, panel configurations, and finishes to meet the specific needs of North American clients.

- Enables brands to create unique, private-label collections with distinct design characteristics.

- Enhanced Aesthetics:

- Custom veneer selections allow for the perfect balance of natural wood appearance and cost efficiency, ensuring that every cabinet reflects a premium look.

Learn more: Ideal Custom Cabinets

9.3 Certified, Health-Safe Materials

- Quality Certifications:

- All products are manufactured using CARB, FSC, and E1 certified materials.

- Ensures that every shipment of veneered particle board cabinets meets stringent health and safety standards.

- Transparency & Trust:

- Full certification documentation accompanies every order, giving contractors and brands confidence in the product's quality and performance.

Learn more: Casta’s ISO-Qualified Cabinet Certification: Setting the Gold Standard for Quality and Reliability

9.4 Reliable Export & Logistics Support

- Efficient Delivery:

- A lead time of 25–40 days to North America, ensuring projects stay on schedule.

- Robust Packaging:

- Export-ready, protective packaging minimizes damage during transit and simplifies customs clearance.

- Streamlined Process:

- Casta’s logistics support ensures that every cabinet arrives in perfect condition, maintaining its pristine appearance.

Learn more: Casta’s Outstanding International Projects

10. Are Veneered Particle Board Cabinets Right for You?

In summary, veneered particle board cabinets offer a highly attractive combination of cost-effectiveness, aesthetic appeal, and performance. They are an excellent choice for contractors and cabinet brands looking to achieve a natural wood appearance without the premium price tag of solid wood, making them particularly suited for mid-range residential and commercial projects.

While these cabinets do have some limitations—such as lower moisture resistance compared to marine plywood—these issues can be effectively managed through proper treatments and quality manufacturing processes. By choosing veneered particle board cabinets from a trusted supplier like Casta Cabinetry, you can enjoy consistent, high-quality results that meet modern design standards and market demands.

For those looking to optimize costs, streamline logistics, and maintain a high-end appearance, veneered particle board cabinets are a smart, sustainable choice. Embrace the trend, and take advantage of the innovative, cost-effective solutions that these cabinets offer.

11. FAQ

What are veneered particle board cabinets made of?

Are veneered cabinets good for kitchens?

What are the most common veneers for kitchen cabinets?

How do veneered cabinets compare to melamine or laminate finishes?

Can veneered particle board cabinets be customized?

Top Cabinet Manufacturers in Florida: A Capability-Based Buy...

Cabinet manufacturers in Florida play a critical role in one of the fastest-growing construction markets in North Americ...

01/10/2026 | David Nguyen

Top North Carolina Cabinet Manufacturers | Best NC Kitchen ...

North Carolina cabinet manufacturers have long been trusted across the U.S. thanks to the state’s deep heritage in woodw...

01/08/2026 | David Nguyen

Top Cabinet Manufacturers in Arizona | Best Arizona Kitchen ...

Cabinet manufacturers in Arizona have gained increasing attention as construction activity accelerates across Phoenix, T...

01/06/2026 | David Nguyen

Top Cabinet Manufacturers Indiana | Best Indiana Kitchen Cab...

Cabinet manufacturers Indiana have become increasingly relevant as contractors and developers look for dependable Midwes...

01/04/2026 | David Nguyen

Contact us

Casta is always ready to listen and answer all customers' questions