Rising material costs and the demand for large‑scale production put pressure on project budgets and timelines. Contractors and designers need cabinetry solutions that balance affordability, scalability, and durability. Blockboard cabinets, constructed from bonded wood strips with a hardwood veneer, meet these challenges by minimizing waste with large sheet formats, enabling high‑volume automated production, and offering a dense, stable core for long‑lasting performance.

This guide covers blockboard’s composition, blockboard advantages and blockboard disadvantages, the main types of blockboard, and a detailed comparison with plywood—so you can select the ideal material for multi‑unit housing, commercial builds, or custom residential installations.

Table of Contents

1. What Is a Blockboard? A Material Overview for Buyers

1.1 Blockboard Composition

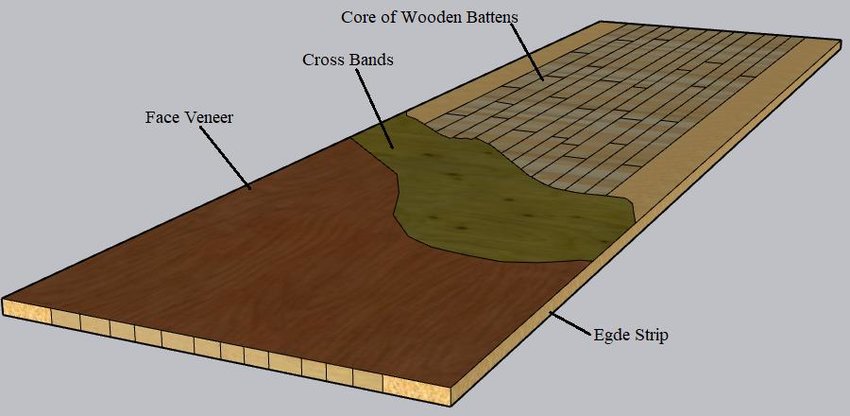

A blockboard cabinet is an engineered wood product crafted by bonding softwood strips—usually pine or poplar—in an edge-to-edge configuration. This core is then laminated with a thin veneer, typically made from hardwood, although softwood veneers can also be used. The process involves using high-pressure adhesives and heat, resulting in a material that is both lightweight and structurally sound.

- Core: Consists of continuous softwood strips.

- Outer Layer: Veneers add an attractive, natural look.

- Adhesives: High-quality resins ensure a durable bond.

The consistent structure of blockboard provides a reliable platform for cabinetry that can easily accept various finishes, making it an ideal choice for projects that demand both aesthetic appeal and cost-effectiveness.

Learn more: What are laminate cabinets

1.2 Technical Properties

Blockboard is prized for its technical properties:

- Density: Typically between 500–700 kg/m³, making it lighter than traditional plywood.

- Thickness Range: Commonly available in 12mm to 25mm, suitable for various applications.

- Screw-Holding Strength: Superior to MDF, ensuring reliable assembly.

- Cost Efficiency: Offers significant savings (20–30% less expensive than premium plywood) while delivering consistent quality.

These characteristics make blockboard a preferred material for contractors and cabinet/furniture brands looking to produce high-quality, cost-effective cabinets in bulk.

1.3 Typical Use in Cabinetry

Blockboard finds extensive application in cabinetry:

- Common Applications:

- Cabinet shutters and doors in kitchens, bathrooms, and storage units

- Side panels, partition walls, and back panels for both residential and commercial installations

- Internal components such as shelving, drawer boxes, and carcass panels

- Flat‑Pack & Modular Systems:

- Bulk production of flat‑pack cabinet kits for multi‑unit housing, student dormitories, and co‑living developments

- Modular RTA systems that ship efficiently, assemble quickly onsite, and maintain consistent quality across large runs

- Ideal for developers and contractors who require scalable, cost‑effective solutions with minimal on‑site labor

- Industry Benefits:

- Its lightweight nature facilitates easier transportation and assembly, which is especially beneficial for flat-pack or RTA (Ready-to-Assemble) systems.

2. 5 Blockboard Advantages That Matter for Cabinet Projects

Blockboard cabinets provide several advantages that make them a compelling option for many projects.

2.1 Lightweight but Strong

Blockboard is significantly lighter than plywood, which translates to easier handling, lower shipping costs, and simplified installation processes. This advantage is particularly beneficial in the RTA and modular cabinets industry. Despite its lightness, blockboard offers adequate strength for many applications, such as cabinet doors and internal panels.

2.2 Excellent Screw-Holding Capacity

Blockboard demonstrates impressive screw-holding strength, which is crucial for applications where cabinets are subject to frequent use. Its performance in this regard is comparable to plywood and notably superior to MDF. Enhanced fastening ensures that cabinet components remain secure over time, even with regular operation.

Learn more: Difference between mdf and mfc vs plywood vs hdf

2.3 Resistant to Bending and Warping

The natural alignment of the softwood strips in the blockboard contributes to its high resistance to bending and warping. This makes it especially useful for long panels or tall cabinet doors where maintaining a uniform shape is critical. Contractors benefit from a consistent, stable material that holds its form even under varying environmental conditions.

2.4 Cost-Effective for Large-Scale Orders

Blockboard is 20–30% cheaper than premium plywood while delivering comparable strength and durability. In a 150‑unit apartment complex, switching to blockboard can save developers over $50,000 on cabinetry costs alone. Educational facilities outfitting 20 classrooms can cut material spend by around $15,000, freeing budgets for technology or furnishings. Hotel projects with 200 rooms see a 25% reduction in wardrobe and vanity unit costs, allowing for upgraded guest amenities. Retail chains rolling out display cabinets in 30 stores can reinvest their savings into store décor or marketing.

2.5 Easy to Machine and Customize

Blockboard is well-suited for CNC routing, edge banding, and various finishing processes. It accepts a range of surface treatments such as laminate, veneer, paint, or melamine, offering versatility in design. This ease of customization allows for tailored solutions that meet specific aesthetic and functional requirements, making blockboards a popular choice among custom cabinet manufacturers.

Learn more: Top rated cabinet manufacturers

3. 3 Disadvantages of Blockboard (And How to Address Them)

While blockboarding has many benefits, it is not without its limitations. Here, we explore the key disadvantages and provide practical solutions to manage them.

3.1 Not as Durable as Solid Plywood

- Disadvantage:

Blockboard cabinets may not match the long-term durability of solid plywood, particularly in heavy-load applications, with a life expectancy that can be significantly shorter.

- Solution:

Use blockboard in non-load-bearing areas such as cabinet shutters and side panels. For critical load-bearing applications, consider hybrid designs that incorporate solid wood elements, thus extending the lifespan.

Learn more: Industrial Cabinets Made in Vietnam: Durability and Functionality for Demanding Applications

3.2 Core Gaps Can Affect Finish if Poorly Manufactured

- Disadvantage:

Inconsistent core manufacturing can result in gaps, leading to veneer bubbling or uneven finishes.

- Solution:

Partner with reliable manufacturers like Casta Cabinetry that employ rigorous quality control measures. Advanced, automated veneer presses and consistent adhesive application help prevent these issues, ensuring a smooth, uniform finish.

3.3 Limited Moisture Resistance

- Disadvantage:

Standard blockboard edges absorb humidity, leading to swelling at door and panel seams and causing screw holes in hinges and drawer runners to loosen, which undermines cabinet integrity over time.

- Solution:

Specify E1‑rated or moisture‑resistant blockboard panels, seal all cut edges with 1 mm PVC/ABS edge banding plus a UV‑cured moisture barrier, install continuous silicone gaskets at carcass joints, and pre‑drill with brass or plastic screw anchors before fitting hinges and slides to maintain long‑term stability.

4. Blockboard vs. Plywood: A Side-by-Side Analysis

To help contractors and brands choose the right material for each cabinet component, here’s a feature comparison and a clear mapping of where to use blockboard versus plywood.

Feature Comparison

| Feature | Blockboard | Plywood |

| Cost per Sheet (18 mm) | $20 – $35 | $30 – $50 |

| Weight | Lighter—reduces shipping & handling costs | Heavier—provides extra structural stability |

| Screw‑Holding Strength | High—suitable for non‑load‑bearing applications | Very high—preferred for structural, load‑bearing uses |

| Moisture Resistance | Medium—requires MR treatments for kitchens/baths | High—ideal for moisture‑prone environments |

| Warping Resistance | High—consistent core structure | High—advanced layered construction |

| Processing Time | Faster—uniform structure | Slightly longer—complex layering |

| Installation Stability | Adequate—best for partitions & non‑structural panels | Superior—excellent for carcass & load‑bearing sections |

| Maintenance Costs | Lower initial cost; may need periodic refinishing | Higher upkeep; long‑term durability |

Component Roles

| Cabinet Component | Blockboard | Plywood |

| Door Fronts | Ideal for painted or veneered doors; lightweight | Best for solid‑wood or high‑end veneer finishes |

| Side Panels | Suited for mid‑range residential and commercial projects | Preferred for high‑load and moisture‑exposed panels |

| Carcass Panels | Use for non‑structural partitions or budget builds | Recommended for structural support and base units |

| Shelves | Good for moderate loads in closets & utility rooms | Ideal for heavy loads and long shelf spans |

| Back Panels | Decorative or light‑duty storage backing | Provides robust support for stability |

| Drawer Boxes | Acceptable for light‑use drawers | Standard choice for durable, heavy‑use drawers |

- Best Use:

- Blockboard: Ideal for cabinet shutters, partitions, and budget-conscious projects.

- Plywood: Preferred for cabinet carcasses and high-load applications.

- Target Audience/Project Type:

- Blockboard: Best for mid-range residential, multi-family, and commercial spaces prioritizing aesthetics and cost efficiency.

- Plywood: Suited for projects requiring high strength and durability, such as luxury homes and heavy-use commercial settings.

Learn more: Sourcing Cabinets and Furniture from Vietnam: Your Ultimate Guide

5. Types of Blockboard Cabinets

Blockboard cabinets come in several variations, each with its own unique characteristics and applications. In this section, we dive deep into the different types of blockboard cabinets and discuss their appearance, technical benefits, and ideal use cases. These variations allow contractors and cabinet brands to choose the perfect solution based on their design priorities and project requirements.

5.1 Moisture-Resistant Blockboard

- Characteristics:

- Features a treated core and specialized adhesives formulated to resist humidity, ensuring that blockboard cabinets maintain their structural integrity in moist environments.

- The finish is often smooth and designed to prevent water penetration, which preserves both the appearance and durability.

- Enhanced appearance due to protective coatings that give the cabinet a consistent, clean look even in high-moisture areas.

- Applications:

- Ideal for kitchen and bathroom cabinet fronts where moisture is a constant concern.

- Frequently used in areas such as laundry rooms or utility spaces, where maintaining the pristine appearance of blockboard cabinets is essential despite exposure to water.

Learn more: Waterproof outdoor kitchen cabinets

5.2 Veneer-Faced Blockboard

- Characteristics:

- Finished with a high-quality wood veneer—commonly oak, ash, or walnut—that offers a natural and upscale appearance.

- The veneer adds a luxurious, authentic wood grain look, making these blockboard cabinets highly attractive in environments where aesthetics are a priority.

- The appearance can be further enhanced by various finishing techniques such as staining, clear-coating, or UV lacquering, ensuring that the cabinets look refined and elegant.

- Applications:

- Suitable for mid-range residential or retail cabinetry, where the appearance of blockboard cabinets is key.

- Often chosen for custom kitchen projects, high-end office spaces, and boutique retail displays that demand both cost efficiency and a high-end look.

5.3 Laminated Blockboard

- Characteristics:

- Pre-laminated surfaces using melamine or High-Pressure Laminate (HPL) provide a uniform finish that enhances the overall appearance of blockboard cabinets.

- Laminated blockboard offers a smooth, consistent look that can mimic various textures and colors, making it versatile for different design themes.

- The lamination process also boosts durability, ensuring that the attractive surface remains intact even with frequent use.

- Applications:

- Common in mass-produced cabinets for schools, offices, or apartments, where cost efficiency is paramount.

- Ideal for projects where a consistent, modern look is desired across multiple units, such as in multi-family housing or commercial installations.

5.4 Fire-Rated Blockboard (Optional)

- Characteristics:

- Specially treated to meet stringent fire safety standards, these blockboard cabinets incorporate materials and adhesives that resist ignition and slow the spread of fire.

- While the primary focus is on safety, the fire-rated finish is designed to maintain a clean, professional appearance suitable for high-end applications.

- The aesthetic appeal remains intact, ensuring that even fire-rated blockboard cabinets look modern and sophisticated.

- Applications:

- Used in environments where fire resistance is mandatory, such as public buildings, hospitals, or specialized facilities.

- Particularly beneficial for projects that require both safety compliance and a stylish appearance, providing peace of mind without compromising on design.

6. Certifications That Ensure Blockboard Safety & Performance

Certifications play a critical role in guaranteeing product quality and safety in cabinet manufacturing:

- CARB (California Air Resources Board):

- Value: Limits formaldehyde emissions, ensuring safer indoor air quality.

- Importance: Essential for regulatory compliance and protecting consumer health in North America.

- E1 Standard:

- Value: Indicates low-emission levels of adhesives used in manufacturing, which minimizes VOCs.

- Importance: Critical for global trade and ensuring that products meet international safety standards.

- FSC (Forest Stewardship Council) Certification:

- Value: Verifies that wood is sourced from responsibly managed forests.

- Importance: Supports sustainable practices and enhances the brand reputation of eco-friendly products.

- Casta's Commitment:

- Every blockboard cabinet supplied by Casta comes with full certification documentation, ensuring all materials are CARB, E1, and FSC certified. This commitment guarantees that every product meets the rigorous standards demanded by contractors and cabinet brands.

Learn more: Cabinet certification

7. Why Contractors & Brands Should Consider Blockboard

Blockboard cabinets offer an exceptional blend of affordability, performance, and high-end appearance that makes them an ideal choice for modern cabinetry projects. These blockboard cabinets not only deliver a natural wood look but also provide the structural and cost benefits required for scalable, large-scale projects.

Below are the key reasons why investing in blockboard cabinets is a smart move for contractors and cabinet brands.

7.1 Ideal for Scalable Cabinet Projects

- Advantage:

- Blockboard cabinets are perfectly suited for projects such as multi-unit housing, schools, retail chains, and other budget-conscious builds. Their engineered construction enables uniformity across large orders.

- Impact:

- Their cost efficiency allows for mass production without compromising on the high-quality appearance of blockboard cabinets. Contractors can achieve consistent, attractive finishes that maintain a natural, upscale look while keeping production costs low.

- Aesthetic Note:

- The natural veneer finish on many blockboard cabinets provides a sophisticated, contemporary appearance that appeals to modern buyers, making them a popular choice for interior designers and brands looking to deliver premium-looking products at a competitive price.

Learn more: Outstanding Projects

7.2 Reliable Quality at a Competitive Price

- Advantage:

- With prices typically 20–30% lower than premium plywood options, blockboard cabinets offer significant cost savings. Despite their lower cost, they deliver a refined, natural wood appearance that rivals more expensive materials.

- Impact:

- This balance of cost and quality enables brands to meet market demands effectively. By choosing blockboard cabinets, contractors and brands can produce attractive, high-end cabinetry that fits a variety of design themes without stretching the budget.

- Aesthetic Note:

- The visually appealing finish of blockboard cabinets—with options for high-quality veneers and custom finishes—ensures that the final product not only looks luxurious but also exudes a contemporary charm that resonates well with modern interior trends.

7.3 Better for Logistics and Installation

- Advantage:

- Due to their lighter weight compared to plywood, blockboard cabinets are easier and less expensive to transport. This weight advantage simplifies installation and reduces the strain on logistics.

- Impact:

- Faster assembly and streamlined logistics lead to lower overall project costs, which is particularly beneficial for both residential and commercial builds. The ease of handling ensures that blockboard cabinets can be installed quickly and efficiently on-site, reducing labor costs and minimizing potential delays.

- Aesthetic Note:

- The ease of installation also ensures that the aesthetic integrity of blockboard cabinets is maintained. Precise installation methods help preserve the seamless appearance and high-quality finish of the cabinets, contributing to an overall superior look in the finished space.

Learn more: Lead Times & Supply Chain Resilience: Navigating Potential Disruptions

By incorporating blockboard cabinets into their projects, contractors and brands can achieve a high-end, natural wood appearance at a fraction of the cost of solid wood, all while benefiting from the material's excellent performance and logistical advantages. This makes blockboard a truly compelling option for those aiming to deliver stylish, scalable cabinetry solutions in today’s competitive market.

8. Casta Cabinetry: Trusted Blockboard Cabinet Supplier from Vietnam

8.1 Advanced Manufacturing

- State-of-the-Art Facility:

- Operates in a high-tech production facility spanning over 100,000 m² in Vietnam, with more than 90% automation.

- Uses cutting-edge European machinery (HOMAG, Biesse, SCM) to ensure precision and consistency.

- Superior Production Processes:

- Automated cutting, pressing, and edge banding produce blockboard cabinets with a consistently high-end appearance.

- Precision engineering ensures each blockboard cabinet meets rigorous quality standards, with clean edges and uniform finishes that rival solid wood cabinetry.

8.2 OEM & Customization Services

- Tailored Solutions:

- Offers fully customizable options including custom sizes, panel configurations, and a range of finishes tailored specifically for the North American market.

- Enables brands to create unique, private-label collections that showcase the premium look of blockboard cabinets at a competitive price.

Learn more: Ideal Custom Cabinets

- Design Flexibility:

- Provides OEM/ODM services that allow for the integration of unique design elements, ensuring that the final product not only meets functional requirements but also exudes a refined, modern aesthetic.

- Supports extensive customization, from the veneer choice to the final surface treatment, enhancing the natural, upscale appearance of blockboard cabinets.

8.3 Certified, Health-Safe Panels

- Quality Assurance:

- All blockboard panels are CARB, E1, and FSC certified, ensuring low formaldehyde emissions, responsible sourcing, and high product safety.

- This certification process guarantees that every blockboard cabinet is manufactured using premium, health-safe materials that comply with strict North American standards.

- Comprehensive Documentation:

- Every shipment comes with full certification documentation, providing contractors and brands with the confidence that the products meet all required quality and safety benchmarks.

Learn more: Casta’s ISO-Qualified Cabinet Certification: Setting the Gold Standard for Quality and Reliability

8.4 Delivery & Logistics Support

- Efficient Export Process:

- Guarantees a lead time of 25–40 days for delivery to North America, ensuring timely project completion.

- Robust export-ready packaging minimizes damage and simplifies customs clearance, maintaining the pristine appearance and structural integrity of the blockboard cabinets.

- Reliable Shipping Coordination:

- Works with trusted logistics partners to ensure that every shipment arrives in perfect condition, ready for immediate installation.

- Streamlined logistics support reduces downtime and project delays, a critical factor for contractors managing multiple installations.

Learn more: Casta’s Outstanding International Projects

By choosing Casta Cabinetry, contractors and cabinet brands can leverage the benefits of advanced manufacturing, customizable OEM services, stringent quality certifications, and efficient logistics support. This strategic partnership ensures that every blockboard cabinet not only delivers a natural, upscale appearance but also meets the performance and durability standards required in today’s competitive market.

9. Is Blockboard the Right Cabinet Material for You?

Blockboard cabinets offer an ideal combination of affordability, strength, and aesthetic appeal. For contractors, cabinet/furniture brands, and companies in North America, blockboard represents a smart choice for bulk orders and large‑scale projects. With a lightweight yet durable construction, excellent screw‑holding capacity, and cost savings of 20–30% compared to premium plywood, blockboard is designed to meet the demands of modern cabinetry.

While blockboard does have limitations—such as lower moisture resistance and a potentially shorter lifespan in high‑stress applications—these challenges can be effectively managed through careful material selection and advanced manufacturing processes. By choosing blockboard, you not only benefit from a material that delivers a real wood appearance at a reduced price but also gain access to a reliable, scalable solution that supports modern design trends.

When sourced from a trusted partner like Casta Cabinetry, blockboard cabinets come with the assurance of high‑quality production, stringent quality control, and full certification. This makes blockboard a valuable material that balances performance with cost, positioning it as a leading choice for forward‑thinking contractors and brands looking to innovate and stay competitive in today’s market.

Quick Decision Summary

| Project Situation | Use Blockboard? |

| Multi‑unit residential developments | Yes |

| Budget‑conscious commercial projects | Yes |

| High‑humidity environments (e.g., bathrooms) | No |

| Luxury custom/high‑end residential installations | No |

| RTA/Flat‑pack cabinetry systems | Yes |

10. FAQ

What is blockboard made of?

Is blockboard suitable for kitchen or bathroom cabinets?

How does blockboard compare to plywood?

What are the blockboard advantages?

What are the blockboard disadvantages?

Can I customize blockboard cabinets?

Why should I choose Casta Cabinetry for blockboard cabinets?

Top Cabinet Manufacturers in Florida: A Capability-Based Buy...

Cabinet manufacturers in Florida play a critical role in one of the fastest-growing construction markets in North Americ...

01/10/2026 | David Nguyen

Top North Carolina Cabinet Manufacturers | Best NC Kitchen ...

North Carolina cabinet manufacturers have long been trusted across the U.S. thanks to the state’s deep heritage in woodw...

01/08/2026 | David Nguyen

Top Cabinet Manufacturers in Arizona | Best Arizona Kitchen ...

Cabinet manufacturers in Arizona have gained increasing attention as construction activity accelerates across Phoenix, T...

01/06/2026 | David Nguyen

Top Cabinet Manufacturers Indiana | Best Indiana Kitchen Cab...

Cabinet manufacturers Indiana have become increasingly relevant as contractors and developers look for dependable Midwes...

01/04/2026 | David Nguyen

Contact us

Casta is always ready to listen and answer all customers' questions